Shanghai Npack Automation Equipment Co., Ltd. |

|

Automatic olive oil filling machine ,adapts vacuum sucking filling nozzles

The NP-VF automatic olive oil filling machine is designed and

manufacturer by shanghai npack, the machine also suitable for

varies kinds of food oil ,edible oil.cooking oil,palm oil. the filling volume is from 100ml to 1000ml, and 500ml to 5000ml,

If your filling volume is from 100ml-5000ml, one machine is ok,

just need change one set of piston fro 100ml-500ml.

Competitive Advantage of olive oil filling machine

There are many advantages of the automatic oil oil filling

machine

1. PLC control, operation on touch screen

2. Panasonic servo motor driven , automatic adjust the Filling size

on HMI, eg. Users want

To fill 500g oil, users just input the number 500, then the machine

will automatic adjust

3. It is volumetric by piston, high filling accuracy

4. Easy adjustment, and tools free

5. The soft tubes or pipes on the filler are adapt world brand

Toyox from japan

6. Specially made rotary valve for oil transfer

7. O seals and Rings are specially chosen for oil

Technical Parameter:

Filling Nozzles | : | 1-16Nozzles |

Production Capacity | : | 800 -5000Bottles Per Hour |

Filling Volume | : | 100-500ml,100ml to 1000ml, 1000ml to 5000ml |

Power | : | 1500W to 3000W, 220VAC |

Accuracy | : | ±0.1% |

Driven | : | Panasonic Servo Motor |

Inerface | : | Schneider Touch Screen |

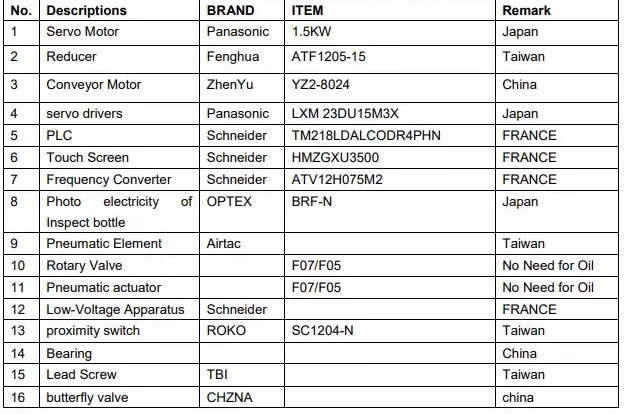

Configuration List

Installation and Debugging

-- We will send engineers to carry out installation and debugging

of the equipment in buyer's place if requested.

-- The cost for International double ways air tickets,

accommodations, food and transportations, medical shall be paid by

Buyer for the engineers.

-- The normal debugging term is 3-7days, and the buyer should pay

US$80/day per engineer.

-- If customer do not require above, then customer need to be train

in our factory. Before installation, the customer need read the

operation manual firstly. Meanwhile, we will offer an operation

video to customer.

Training

-- We offer machines training system; the customer can choose

training in our factory or in customer workshop. The normal

training days are 1-2 days.

Warranty

-- The sold machine will be guarantee in one year.

-- In the guarantee year, any spare parts broken due to supplier's

quality issue the spare parts will be supplied free for customer,

customer need to pay the freight cost if the parcel weight more

than 500gram.

-- The easy wearing out spare parts are not in the warranty terms,

such as O rings, belts which will be supplied with the machine for

one year using.