Guangzhou Kinte Electric Industrial Co., LTD |

|

Verified Suppliers

|

|

Flexible Main Line Welding System

1. Process introduction:

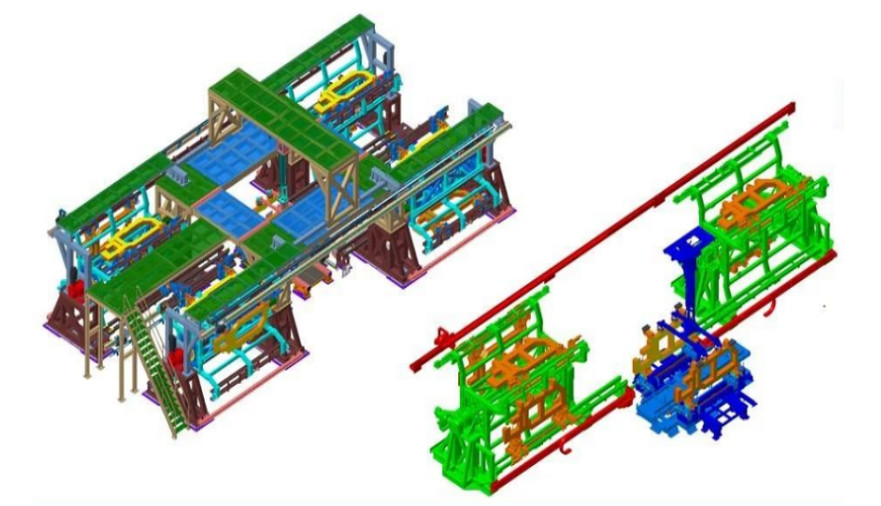

The main welding wire flexible system is mainly to complete the assembly and welding work of the lower body, side wall, roof and other assemblies. It is possible to switch flexible production lines for more than 4 types of models; using core technologies such as hub-type flexible assembly, warehouse-type flexible assembly, and robot flexible assembly, through technical transformation, the production cycle can be increased to 65JPH, and the automation rate can reach 95%. above.

Pic1

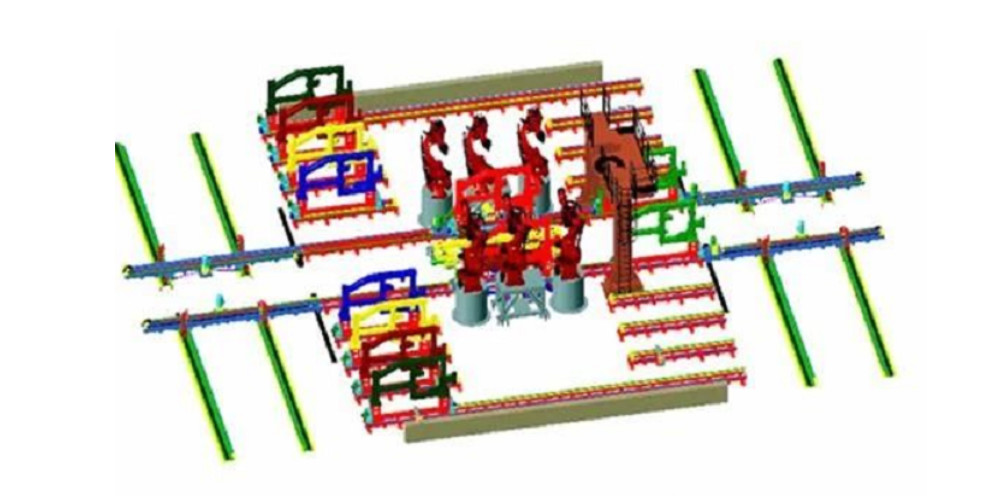

Pic2

2. Project case:

Pic1-4

3. The development trend of automobile welding production line

At present, the development trend of the world's automobiles is from mass production to multi-variety and small-batch production. In order to meet the extensive and diverse needs of automobile consumers and adapt to the fierce competition in the automobile market, major automobile manufacturers in the world continue to shorten the model change Cycle, to speed up the update of vehicle types, so the modern automobile welding line is gradually becoming more flexible in function.

In a narrow sense, the flexible production line generally refers to the mixed production of various models. Various models can adjust the proportion of the entire model arbitrarily according to changes in market demand and under the premise that the total output remains unchanged. Various flexible transmission devices such as elliptical ground circular lines and elevated upper and lower circular lines (as shown in Figure 9) have appeared successively. For example: the T100S/FINR ASSYLINE of Daewoo Motor Corporation of South Korea is to produce the car bodies of three different models of T-100, 3-door, 4-door and 5-door, in mixed flow on the same transmission line.

4. Analysis of the structure and working principle of the transmission device of the automobile welding production line

The following takes the transmission device of the automobile side panel assembly line as an example to analyze its structure and working principle in detail

The transmission device of the side panel assembly line of a certain vehicle type adopts a four-station reciprocating rod device, which can realize horizontal and vertical movement.