Guangzhou Ribo Plastic Packing Machinery Co.,Ltd. |

|

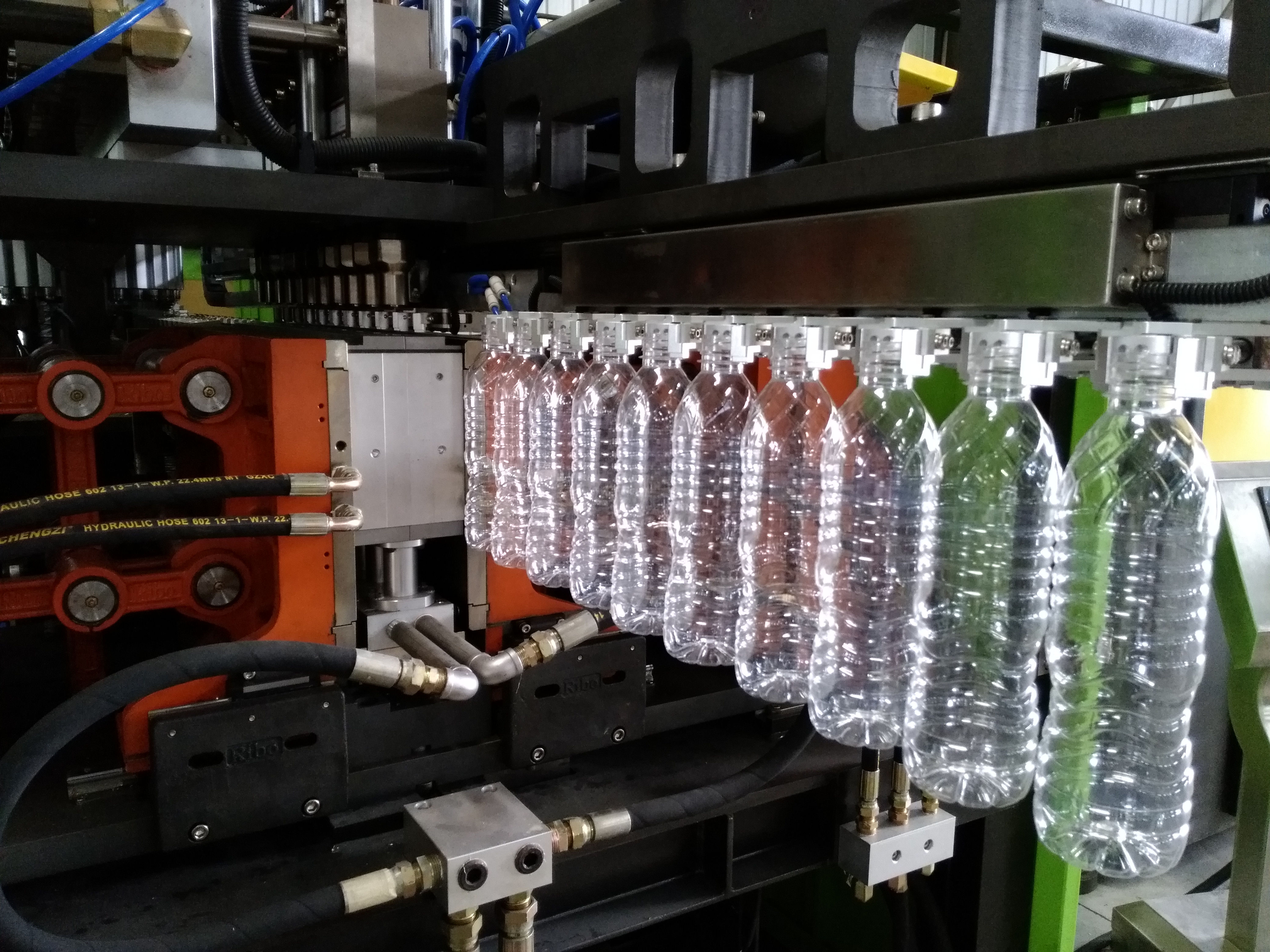

Juice Bottle / CSD Bottle / Edible Oil Bottle / PET Stretch Blow Molding Machine

This series is widely used for making PET bottle for drinking water, carbonated soft drink, medium temperature filling drink, milk,

edible oil, food, daily chemical……ect.

Machine Features

1). Stable performance with advanced PLC.

2). Automatic preform conveyer to save human cost and achieve the

environmental safe.

3).The thermostatic heating system ensure that the heating temperature of each preform surface and internal is

uniform.Hinged oven holders make it easy for the operators to

change infrared tubes and do maintenance.

4). High adjusting performance to enable heat the preforms perfectly by adjust the voltage on the touch screen, which could

adjust the temperature of the infrared lights in the heating ovens,

and keep the proper temperature and humidity invariable.

5). High safeties with security automatic detection device in each mechanical action, which will make the production into a

perfect safe environment, in case of the breakdown in certain

procedure.

6). The high pressure blowing system is equipped with the air recycling device which may reduce the air consumption to

achieve the energy-efficient and environmental safe.

7).Strong clamping force,and the high pressure air supercharged mold locking mechanism is applied which buffs the impact

between mold plates and effectively protects molds. Besides, it does help to reduce the visibility of parting lines on finished

bottles.

8). Two ways of operating: automatic and manual.

9). Low cost,high efficiency,easy operation and maintenance etc,

profited from the fully automatic technological process.

10). The circulating chilling water system can protect the bottle neck against deformation when the preform is being heated.

*The built-in continuous rotating infeed system effectively reduces the space occupied. The consistency of preform position

streamlines the process.This preform feeding system is same with rotary machine.

*Perfect heating system design decrease power consumption.

*Special oven design helps power saving and easy maintain.

*Each lamp position and temperature can be adjusted.

*The homothermal heater adopts auto reflection and closed loop adjusting system which have the power supplied constantly in proportion, not

affected by the fluctuation of voltage. The conveying chain is short pitched and paratactic, which helps to realize slow heating and low power

consumption. As a result, the preform can be heated evenly and easy to blow.

The transmission adopts servo motor for positioning that can orientate the preform-heating base quickly, accurately and steadily

when the machine starts and running.

*Servo motor driven the mold clamping system and triggering off a bottom mold linkage as well which can shorten the mold-clamping time

and improve productivity, and also solve the swelling mold and big

joint line problem with the effect of pressurize plate.

* Servo motor using for stretching to ensure the bottle blowing speed faster and more stable bottle quality.

*Drawer type mold structure design is easy for mold changing. Within one hour can change a mold on the condition of same

bottle neck diameter.

*Human-machine interface control, easy operate and monitor.

*Live production information supervise, auto record production data

everyday

*Failure warning and troubleshooting.

Machine Technical Parameter

| Items | Unit | Model | |

| RiBo-10CR1.5L | |||

| Molding Spec. | Preform Pitch | mm | 96 |

| Preform Heating Pitch | mm | 38 | |

| No.of Cav. | cav. | 10 | |

| Container Spec. | Max.Container Volume | L | 1.5 |

| Neck Diameter Range | mm | 18~30 | |

| Max.Containr Diameter | mm | 88 | |

| Max.Containr Height | mm | 320 | |

| ※※Theoretical Output | bph | 18000~15000 | |

| Power Spec. | Rated Power | KW | 147 |

| Power Consumption | KW | 48~68 | |

| Compressor Spec. | Blowing Pressure | Mpa | 2.5~3.2 |

| Air Consuming | m3/min | 8~10 | |

| Main Machine Spec. | Size | mm | 8480x3400x3000 |

| Weight | Kg | 11000 | |

| Note:*Due to continuous technical development specification would be improved without prior notice. | |||

| *Special designs correspond to customers needs. | |||