NINGBO NIDE MECHANICAL EQUIPMENT CO.,LTD |

|

Verified Suppliers

|

|

Natural Electric Motor Spare Parts Standard Ring Roller Hub Bearing Ball Bearing

Standard Bearing Material

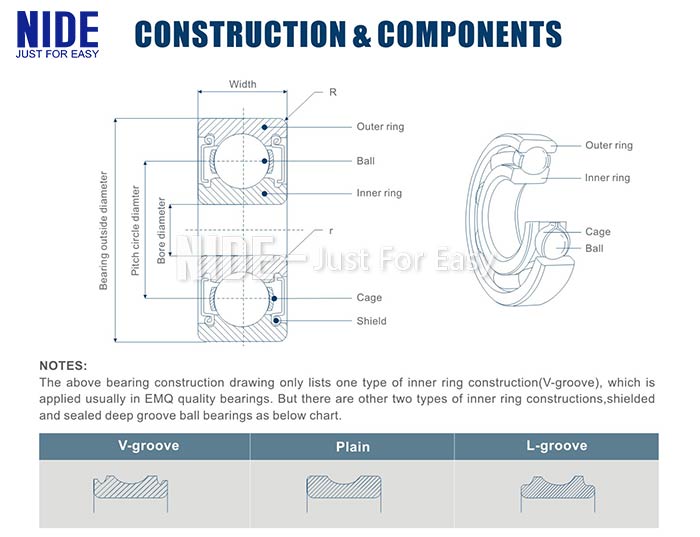

NIDE rolling bearings basically consist of two rings, rolling elements and a cage which keeps the rolling elements at equal intervals. Seals are applied to prevent the bearing from outside affect such as dust or oil invasion. The main purpose of lubricants in rolling bearing is to reduce friction and wear of each elements. Choosing the right material for bearings is especially important for bearings’ application function.

Rings & Rolling Elements

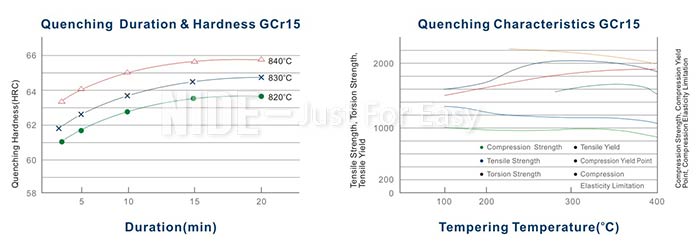

Vacuum degassed, chromium bearing steel Gcr15 is the standard material for precision bearing rings and rolling elements. The material has uniform specification as AISI 52100(America), DIN 100 Cr6(German), JISSUJ2(Japan).

| Chemical Composition % | |||||||||

| Steel NO. | C | Si | Mn | P | S | Cr | Mo | Cu | Ni |

| GCr 15 SAE52100 | 0.95-1.05 | 0.15-0.35 | 0.25-0.45 | ≤0.025 | ≤0.025 | 1.40-1.65 | - | ≤0.25 | ≤0.30 |

NIDE takes special care with its raw material used in its bearings. The raw material applied in the bearing rings and rolling elements is from the companies that sell same quality material to world top class bearing manufacturers in Japan and Europe. Also, NIDE’s latest computerized heat treatment system and technology distinguish NIDE brand bearings form others. It helps the bearing material to reach the characteristics of high level of hardness, high rolling contact fatigue resistance, excellent wear resistance, dimensional stability and excellent mechanical strength which is essential to delay the advent of material fatigue.

Cage Material

Material for NIDE bearing cages is required to have properties of good wear resistance, dimensional stability and good mechanical strength.

Cold-rolled steel is used for pressed cages. (Specification see the below table)

| Chemical Composition % | |||||||

| Sheet Steel NO. | C | Si | Mn | P | S | Ni | Cr |

| JISG 3141 SPCC | <0.12 | - | <0.5 | <0.01 | <0.045 | - | - |

Polyamide resin is applied depending on the type of bearing and the application, but should not be used at temperatures above 120℃or below -40℃. Polyamide cages may be affected by the use of specific lubricants. Brass cages are not suitable in Ammonia (e.g. In refrigeration) Because Ammonia causes season cracking in brass.

So for selection of cage material, it is important to consider the operation conditions.

Shields Material

NIDE bearings employ carbon steel as standard. And the option of AISI-300 stainless steel is available when needed.

Seals Material

NIDE bearings use a variety of sealing materials to meet the requirements of high temperature operation and compatibility with greases. Buna Nitrile is the standard material used, while fluorocarbon, silicone, and Teflon seals are commonly specified for high temperatures.