Greentech (Tianjin) Anti-corrosion Engineering Tech Co.,Ltd |

|

Chemical Resistance Epoxy Ral 1026 9016 9040 9010 White Epoxy Powder Powder Coating

Introduction:

This product adopts phenolic epoxy resin, and for the first time to join the independent research and development of conductive polymer and conductive materials, gather doped conductive and intrinsic conduction advantages as a whole, is specially designed for conductive heavy-duty powder coatings, the coating surface resistance value below 105 , can effectively eliminate the electrostatic accumulation on gas drainage pipeline, to avoid static electricity spark, improve safety performance. High reactivity, strong adhesive force, high crosslinking density, the coating has excellent chemical resistance, solvent resistance, resistance to cathodic stripping, excellent flexibility, impact resistance and other properties.

Feature:

Power Specification:

| Test Items | Technical Indicators | Test Method |

| Appearance | Even color, no caking | visual |

| density(g/cm³) | 1.3-1.7 | GB/T 4472 |

| Non-volatile matter content (%) | ≥99.4 | GB/T 6554 |

| Gel time(s) | 180℃ ≤ 120S 230℃ ≤ 60S | GB/T6554-1986 |

Coating Specification:

| Test Items | Technical Indicators | Test Method | ||

| Appearance | smooth,uniform color, no bubble , no cracking and sinkhole | visual | ||

| adhesion | 1~3 | CJ/T 120-2008 | ||

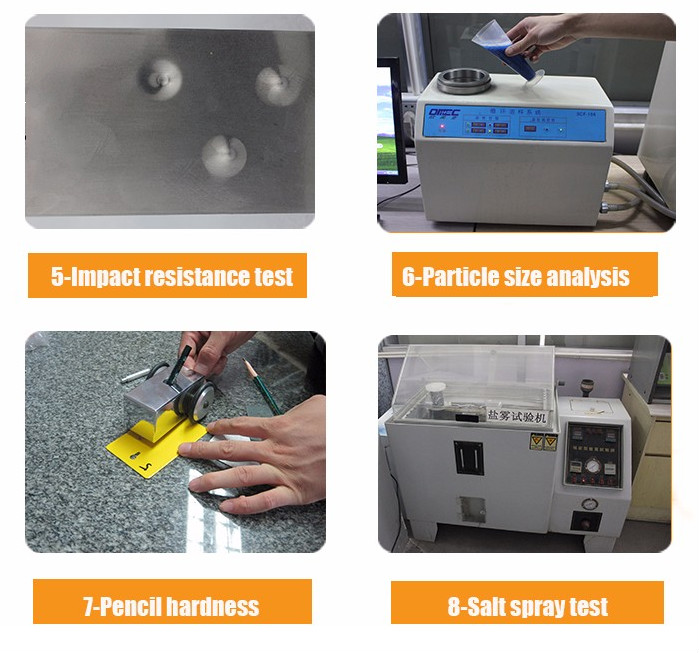

| impact strength | No spalling, no fracture | CJ/T 120-2008 | ||

| surface resistance(Ω.m) | ≤1×106(Ω.m) | GB/T 16906-97 | ||

| abrasion resistance 1000g.1000 turn | ≤20g | GB/T 1768-1979 | ||

| Alcohol flame spray fire test | with flame combustion time average | ≤ 3s | MT 181-88 | |

| with flame combustion time maximum | ≤ 10s | |||

| Flameless combustion time average | ≤ 20s | |||

| Flameless combustion time maximum | ≤ 60s | |||

| Bending test | No striping no cracking on internal coating | CJ/T 120-2008 | ||

| Flatten test (flatness ratio 4/5) | No striping no cracking | CJ/T 120-2008 | ||

Carried Standard: MT 181-88

Application Area: anti-static anticorrosion coating for coal mine gas ventilation and extraction pipe Applicable process: Electrostatic Coating,dip coating, roller coating

Notes: