Easy Disassemble Differential Slip Ring Steel Material Key Type

High Speed

Brief introduction

Easy disassemble differential slip ring mostly used

in the machine which has big dust and the environment is not so good place. It is separate parts for the differential shaft and can replaced separately. The amount of slip exactly compensate for the difference in

speed, thus it can control the tension of each roll precisely,

which ensure the winding quality. And easy disassemble means the

customer can disassemble the ring easy and maintenance will faster and costly.

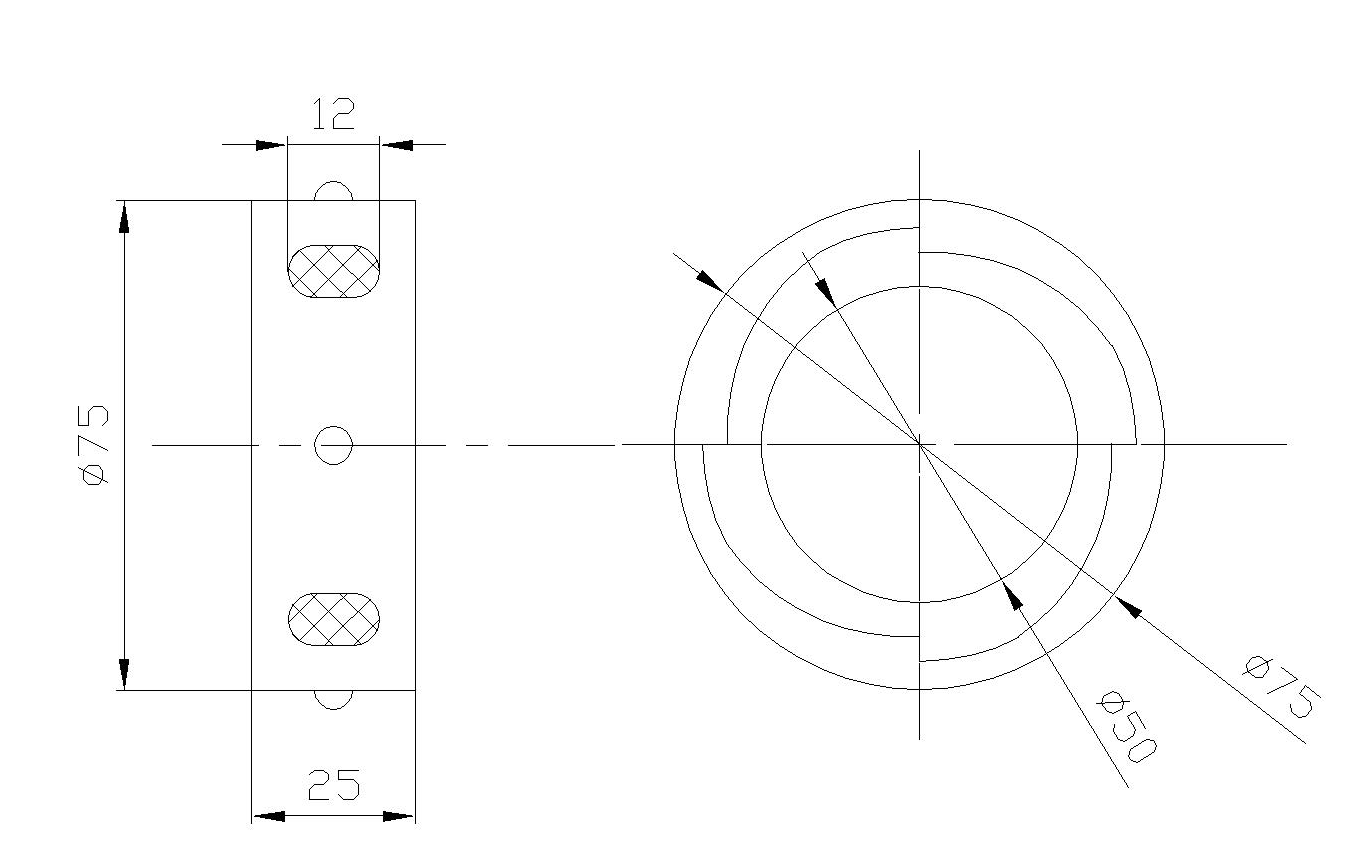

Size of normally differential ring

Outside diameter: Φ75.5mm

The maximum action diameter: Φ78mm

Standard width: 25mm(can change to other size if needed)

Standard internal diamete: Φ60mm (can change to 50mm or 55mm or other sizes if needed)

Types and Specifications of our differential ring (for normal

sizes)

1) Key type (central air pressure and mechanical side pressure type)

A. 3 inch

| 3 inch key type friction element |

| Outside diameter | Φ75.5mm |

| The maximum action diameter | Φ78mm |

| Standard width | 15,20,25,30,35,40,50mm |

| Standard internal diamete | Φ45,Φ50,Φ55mm |

B. 6 inch

| 6 inch key type friction element |

| Outside diameter | Φ151mm |

| The maximum action diameter | Φ156mm |

| Standard width | 20,25,30,35,40,50mm |

| Standard internal diamete | Φ60,Φ75,Φ80mm |

Features

- Difference in material thickness often arises when unwinding

plastic films or other material. In the process of constant

winding, this difference can lead to obvious discrepancy in outside

diameter of roll, and slight discrepancy in winding torque under

this situation. After some winding rotation, some rolls may

start to loosen, leasing to quality decline in product eventually.

- Our differential air shaft with slipping friction can ensure the

highest winding quality, and by keeping proper tension on all rolls

throughout the winding operation, materials will not show any

problem.

- It works under the theory that friction rings slip constantly to

keep same tension, some rings slip faster than others. So tension

of each roll can be controlled accurately, and permanent tension

can also be gained to guarantee the quality of roll.

Principle

- The differential shaft can meet the requirements of high-speed,

error in material thickness, multi-stage tension control, high

precision requirement on tension control, ,uniformity on the

winding end.

- The differential ring on differntial shaft can slip independently,

it is the main part for differential shaft which is with tension

adjustment.

- Controlled by the tension system, make the compressed air which has

a certain pressure come to shaft core, so that it will produce

friction torque between the friction parts and the slip ring.

Advantages

- The use of differential shaft ring improves the stablity of

the slitting machine,espceially for high speed machine.

- The differential shaft combined by differntial rings can make the

accuracy of the winding and the automation.

- Differential shaft ring to wind or unwind precious materials, metal

foil and special paper roll, can greatly reduce the cost

of production.

Application

Applicable to the rewinding or slitting of packaging

materials such as web, plastic sheet, aluminum foil, PVC, plastic

film, insulating material and so on. It is an ideal equipment for

fine cutting materials, Frame fixed good, small gap, high

precision, to ensure the slitting machine can operate in

high-speed.

Why choose CBB Chuangbo machinery

Long history and biggest manufacturer of machinery parts in East

China

Established in 1995 and more than 180 employees, we are biggest

manufacturer of machinery parts (aluminum guide roller, air shaft,

differential shaft) in East China.

High quality of the material

The steel material and the aluminum material supplier is one of the

biggest supplier locally, can make the delivery time faster and

quality stable

Within 24 hours reply for every problems and questions

We are manufacturere and we have 15 engineer in this area, all the

problems and questions will be solved within 24 hours

Inspection

We have a team of 20 workers for inspection department, not only

check the final products, the workers will inspect during the whole

production fromthe very beginning to the end

About CBB Ruian Chuangbo

Ruian Chuangbo Machinery Co., Ltd. established in

1995, is specialized in manufacturing of machinery parts. The

company has advanced production level and scientific research

equipment, the products are matched with printing, packaging,

plastics, paper, textile, pharmaceutical machinery and other

industries.