Dongguan Fodor Technology Co., Ltd |

|

Verified Suppliers

|

|

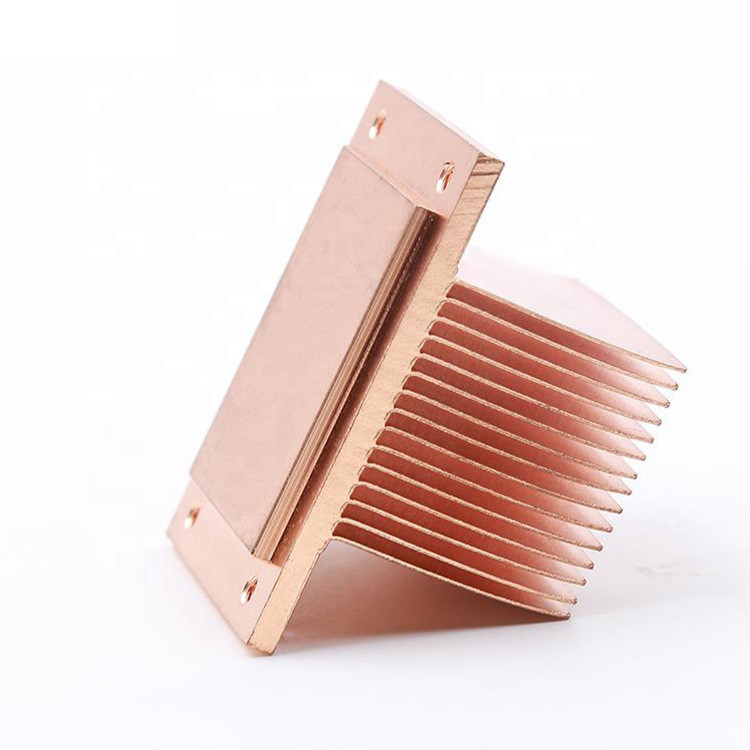

This heat sink is based copper /Aluminum aterial to processing, first of all, we check the raw material dimension is fine or not, the second is that according to the drawing, cutting right length, the third is that accroding to the drawing, use the wood machine to cut the outline dimension, the forth is that use the CNC to do exact dimension, the fifth is do anodizing clear, the last step is riveting, and then inspection/packing. First inspection and patrol inspection are done in processing .

The Skived fin, also known as skiving technology, simply takes an entire piece of aluminum or copper and uses the special skived machine to cut out fins with standard spacing and a certain thickness and height. Because of using high precision cutting technology, the integration of the forming, relative to other processing technology, the same volume of raw materials can be cut out more heat dissipation area, the heat transfer performance is more stable, in the same condition, the cooling performance is more than 1.5~2 times of the efficiency of traditional bonded fin or soldering heat sink, thus greatly improve heat dissipation efficiency and extend the service life of heating components.

| Raw Material | Copper/aluminum |

| Custom Service | Yes, OEM/ODM Service |

| Quality System | ISO9001:2015 |

| Processing Technology | CNC Gear /Wood machining/CNC/Riveting |

| Surface treatment | Deactivation |

| Packing Way | Blister packaging or special packing you would like |

| Application Scenario | Electronic equipment heat sink |

| MOQ Request | 100/500/1000 |

High aspect ratio, straight fin heat sinks that are ideal for compact PCB environments

Fabricated from extruded aluminum, which minimizes thermal resistance from the base to the fins, reduces weight and keeps costs low

Higher performance helps ensure reliable product life at a lower cost than other extruded heat sinks

Comes standard without interface material or with most common pressure sensitive thermal tapes as a custom option

Aluminum heatsink is light in texture, but its strength is relatively high. It is close to or exceeds high-quality steel. It has excellent thermal conductivity and corrosion resistance, good heat dissipation performance, and good energy-saving effect.

After the aluminum heatsink has been surface-oxidized, an oxide film is formed on the surface of the heatsink. This film is tough and dense, preventing further corrosion of the bulk material, increasing the corrosion resistance, wear resistance and appearance of the aluminum material. Aesthetics.

The application areas of aluminum heatsinks are

Power, electronics, communications, machinery, automobiles, solar photovoltaic power generation, wind power, construction machinery, air compressors, railway locomotives, household appliances and other industries.

RFQ

Which fin shape is best for heat sink?

In general, a wavy fin heat sink should perform better under

natural and forced convection due to the increased surface area

created by the fins. This feature can easily be manufactured with a

die. The “waviness” can be adjusted to increase surface area

resulting in a positive impact on thermal performance.

Does copper make a good heat sink?

A Copper Heatsink is sometimes used as a heatsink as it is a good

conductor of heat. This can be observed if you heat one end of a

piece of copper, the other end will quickly reach the same

temperature. Copper is used in many heating applications because it

doesn't corrode and has a high melting point.

What grade of copper do you use for a heat sink?

Copper Heat Sink

With a thermal conductivity of around 400 W/m-K, copper is used

when heat sinks need a performance boost. Typical alloys for copper

plate is CDA110 (391 w/mK). The drawback is copper is 3 times

heavier and twice the cost of its aluminum counterpart. It is also

slightly slower to work than aluminum.