Dongguan Xinlong Non Woven Machinery Equipment Co., Ltd. |

|

Verified Suppliers

|

|

15PCS/Min 7.5KW Ultrasonic Filter Bag Slicer With Freely Selectable Teeth For Side And End Fusion

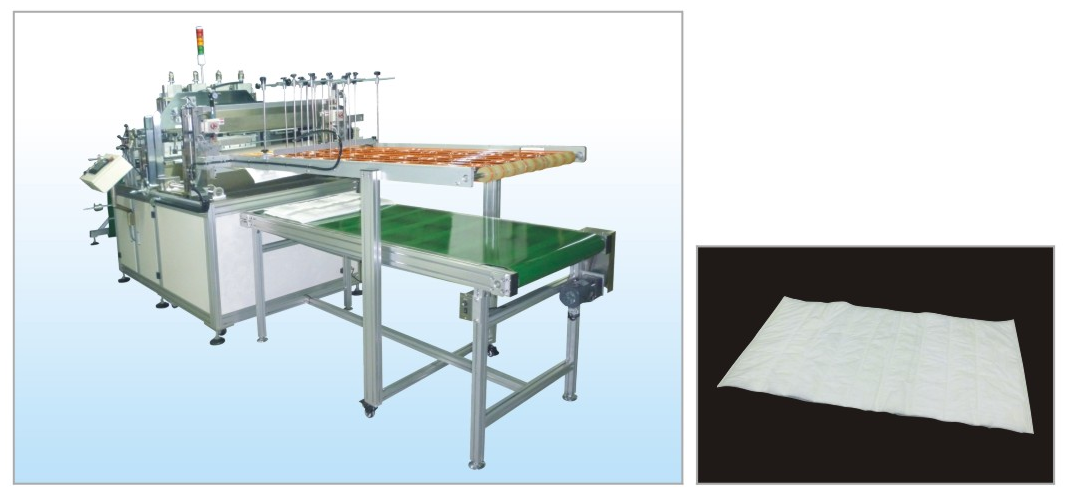

XL-60 Ultrasonic Nonwoven Filter Bag Dust Bag Slicing Machine

XL-60 is a special machine for cutting non-woven primary and secondary filter bags, from raw material to finished product is an automatic operation. It is neat, time-saving, and the cutting length can be adjusted freely.

Operator Safety: The machine incorporates safety features such as safety interlocks and emergency stop buttons to ensure operator safety during operation.Easy-to-use Controls: The machine is equipped with user-friendly controls and a graphical interface, making it easy for operators to set slicing parameters and monitor production.

Quality Assurance: The ultrasonic slicing technology ensures consistent and precise cuts, resulting in high-quality nonwoven filter bag dust bags that meet industry standards.Durability: Constructed with high-quality materials, the machine is designed for durability and longevity, ensuring reliable performance over an extended period.Integration with Production Lines: The machine can be easily integrated into existing production lines, enabling seamless and automated production processes.

MACHINE CHARACTERISTICS:

1. the whole machine is made of aluminum alloy structure, which is oxidized and sturdy without rust.

2. PLC program control, servo motor drive, human-machine interface operation, high stability, excellent performance, no material can automatically stop. If there is any problem during production, the human-machine interface will automatically show the place for troubleshooting, saving time and making the production capacity more efficient.

3. Maximum diameter of filter media: 1000mm.

4. Maximum working width of filter media: 720mm.

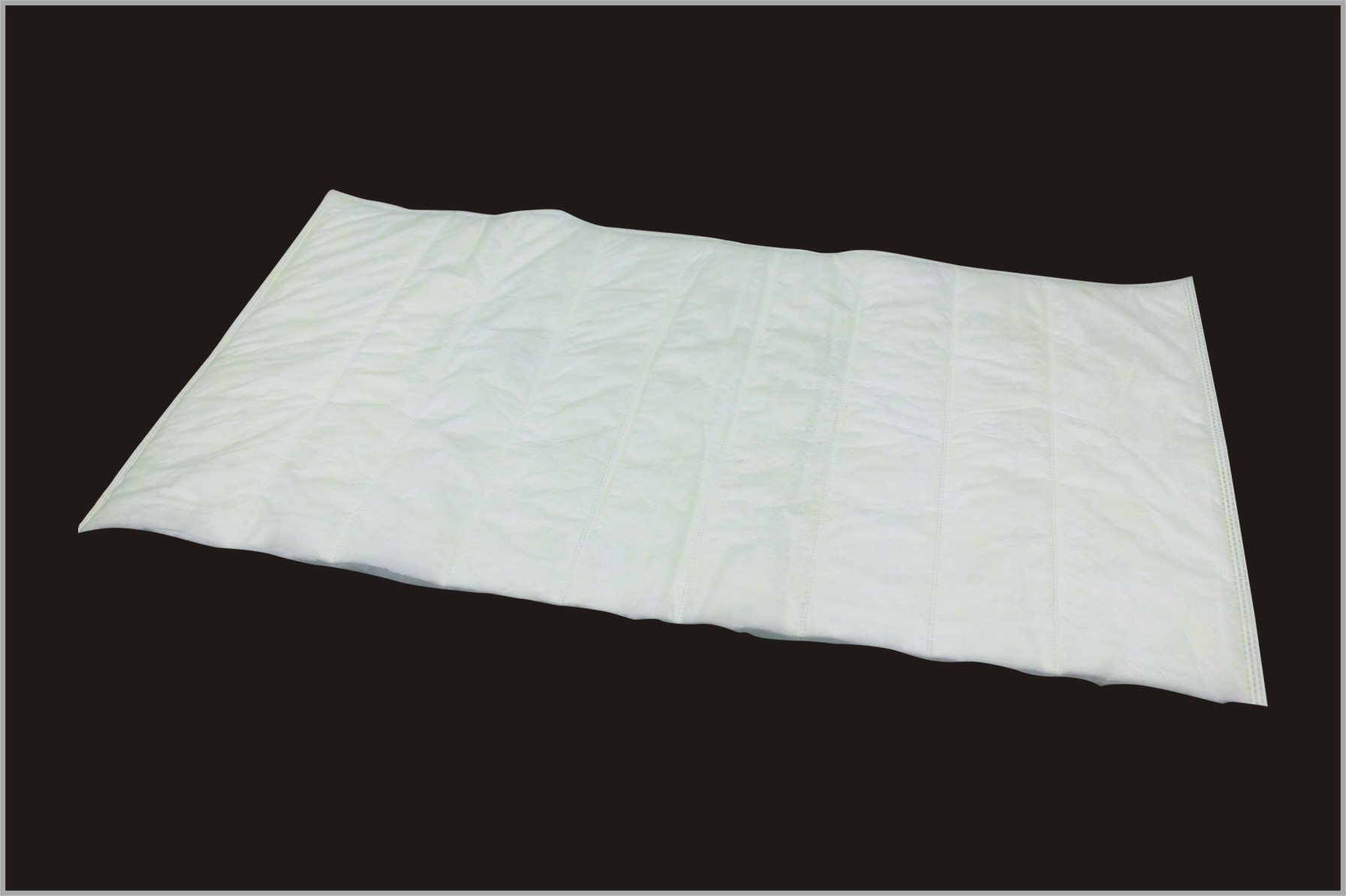

5. Width of finished product: 675mm.

6. Side fusion and end fusion can be freely selected.

7. Length of finished products (bags) can be freely selected.

8. 4 to 6 sets of ultrasonic synchronous welding.

| Machine size | 6400 (L) *1650 (W) *2100 (H) mm |

| Power supply | 1P 220V 3P 380V |

| Air pressure | 0.6-0.7MPa |

| Production capacity | Melt bottom slicing 15PCS/min |

| Power consumption | 7.5KW |

Our advantage

SCALE ADVANCED PRODUCTIVITY

The company has gathered a group of experts who have been engaged

in production site maintenance, operation control, and machine

debugging for many years. With experienced staff. For long-term

operation of industrial equipment due to disturbance Difficulties

and frequent detects, production and design put forward solutions,

let the solutiongs in the design Stages are field-tested to

maximize the effectiveness of the solution at the lowest cost.

PROFESSIONAL R&D TEAM

At the beginning of its establishment, Xinlong started to cultivate

a professional R&D technical team, always pay attention to the

latest development in the field of non-woven fabrics, and closely

track new technologies at home and abroad. The R&D team has

been accumulating for many years and has maintained professinoal

sensitivity.

EQUIPMENT MANUFACTURING TEAM

The company has gathered a group of staff with many years of rich

exerience. Aiming at some difficulties and frequent defects that

have caused long-term disturbance to the operation of equipment in

the industry, production and design propose solutions, allowing the

solution to undergo on-site inspection during the design stage, so

that the solution can achieve the strongest effectiveness and the

lowest cost.