Changzhou Aidear Refrigeration Technology Co., Ltd. |

|

| 1 | Tube Material | Copper tube / Aluminum tube /Bundy tube |

| 2 | Tube Diameter | Φ3-12mm |

| 3 | Tube Wall Thickness | 0.3-1.0mm |

| 4 | Bending Capacity | Single tube |

| 5 | Bending Angle | 1~180 degree |

| 6 | Bending Radius | R11~R30 |

| 7 | Bending Times | Up to 110 times/cycle |

| 8 | Feeding length | 0-700mm/time, max. 3 times |

| 9 | Rotary Table Size | Φ2000mm |

| 10 | Control System | PLC control / Touch Screen |

| 11 | Air Pressure | 0.5-0.6MPa |

| 12 | Motor Power | 13KW |

| 13 | Electric System | 380V, 50Hz, 3Phae (Customized) |

| 14 | Dimension | 4800 x 1300 x 1680 mm (Excluded Table) |

| 15 | Weight | About 3000 KG |

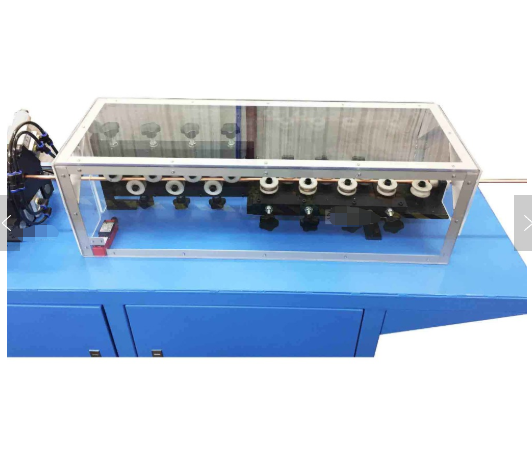

Main Features

1. Three-part clamping die to minimize tube distortion, get smooth

cutting end surface.

2. High accuracy concentricity ensures to get good welding quality

in following process.

3. Chipless cutting with 360°rotary cutting and stretching with two

points clamping.

4. Patented special designed servo control bending system for

different bending direction and bending angle in exact size.

(Patent No.: ZL 2011 1 0092227.X)

5. Patented special designed bending tools ensure exact bending

radius, less deformation and good appearance (Patent No.: ZL 2011 2

0107426.9)

6. Patented special designed bending structure ensures the stable

performance for up to 10-12 grouped tubes in one time. (Patent No.:

ZL 2009 2 0013741.8)

7. Servo drive system, PLC control system, and touch screen control

to get high accuracy product size with easy operation and

maintenance.

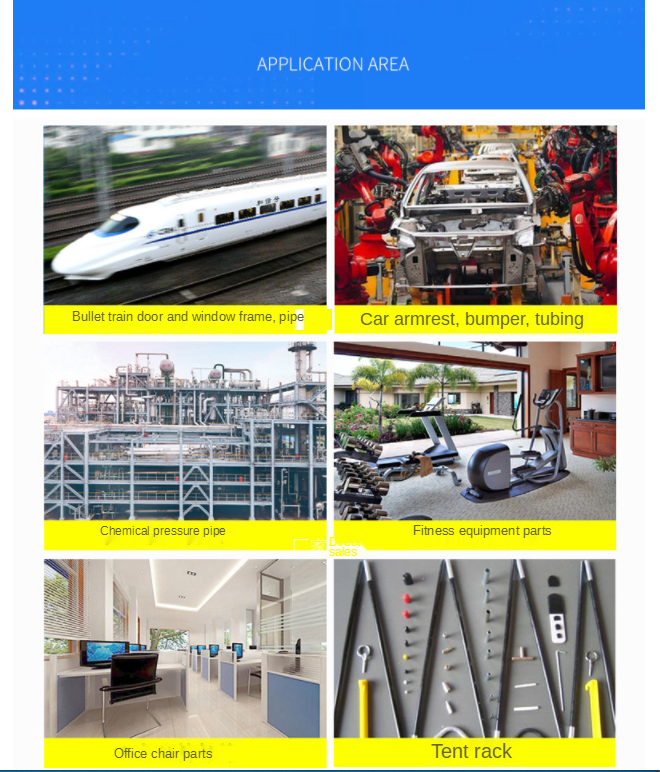

Application

Mainly used for bending non-ferrous or ferrous metal pipes, can be applied to building materials, shipbuilding, chemical industry, metallurgy, boilers and heavy machinery manufacturing and other sectors. The products are mainly used for construction of circular steel structures, tunnel supports, roof bending beams, underground projects, aluminum doors and windows, canopies, package cylindrical endoskeleton, lanai handrails, shower doors, production line tracks, fitness equipment and many other industries. Medium-frequency bending is widely used in the prefabricated pipeline of electric power, petroleum, chemical, marine, nuclear industry and other engineering fields. Frequency bending process is to be bent part of the steel pipe set on the induction circle, with a mechanical rotating arm stuck to the head, in the induction circle into the medium frequency current heating steel pipe, when the steel pipe temperature rises to a plastic state, the steel pipe in the back end of the mechanical thrust propulsion, bending, bending out of the steel pipe part of the rapid cooling with coolant, so that the side heating, side propulsion, side bending, side cooling, continuous bending out of the pipe.