Changzhou ADV Heat Exchanger Co., Ltd |

|

4.5~271kw compressor after cooler of plate fin air to air heat exchanger

To Selected the appropriate model, simply determine compressor horsepower, and select the model from the chart

(All dimensions and technical characteristics can be designed according to your requirement, please contact us if you need customization)

Material Description & Working Situation

Main Cooler Body | Aluminum |

Housing | Powder painted steel |

Fan Guard | Galvanized plate |

Fan Blade | Polypropylene |

Maximum Working Pressure | 250 PSI |

Maximum Working Temperature | 110℃ |

Compressor After Cooler Technic Specification : (took from 220 KW)

| SPECIFICATION | OIL/Air after cooler | |

| Item number | ADV-CMP009 | |

| Technical data(Standard values) | ||

| Compressor driving power | KW/HP | 160/220 |

| Oil cooling power | KW | 122 |

| Air cooling power | KW | 37 |

| Oil flow | Lit/min | 120 |

| Air flow | Kg/hr | 2100 |

| Cooling Air flow | Kg/hr | 18,000 |

| Approximate cooler dimensions | ||

| A | mm/inch | 840 |

| B | mm/inch | 382 |

| A+B | mm/inch | 1222 |

| C | mm/inch | 1120 |

| D | mm/inch | 1270 |

| E | mm/inch | 95 |

| Max working pressure | bar(g)/psig | 15/218 |

| Test Pressure | bar(g)/psig | 20/290 |

| Air cooler connecting slot[G"] | inch | 2(M+P) |

| Oil cooler connecting slot[G"] | inch | 1-1/2(N+O) |

| Cooler weight approx. | Kg/lb | 108.5 |

| Fan speed | rpm | |

| Fan diameter | mm/inch | |

| Oil inlet temperature | ℃ | Max 120 |

| Air inlet temperature | ℃ | Max 120 |

LAB & Test

1.Leak Test of Every Unit

2.Performance Test ( Optional)

| Performance Test: | Compressed Air System | Water Glycol System | Water Glycol System |

|---|---|---|---|

| Flow: | 0-48Nm3/min | 400L/min | 600L/min |

| Temp: | ≤200°C | ≤100°C | ≤110°C |

| Max. heating power: | 110KW | 180KW | 240KW |

3. Pulse Test ( Optional)

4. Viberation Test ( Optional)

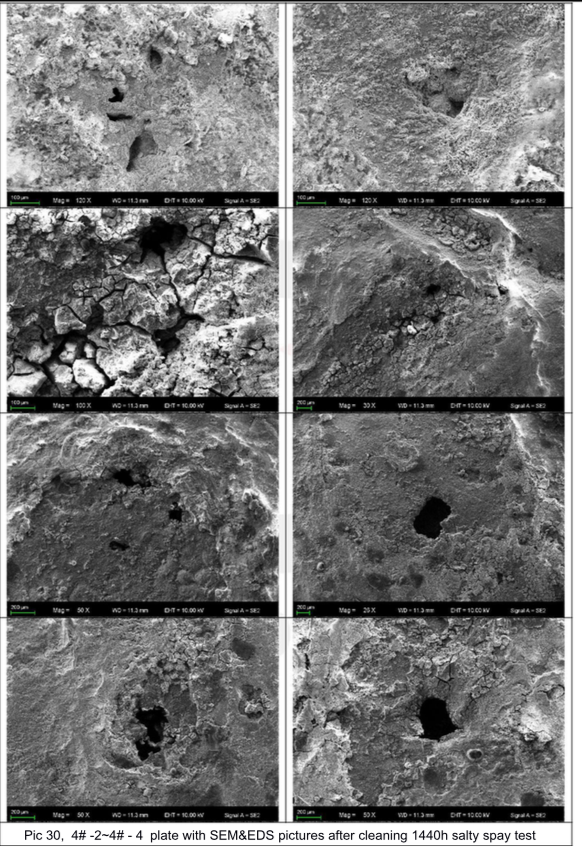

5. Salty Spay Test ( Optional)

we can offer C5 standard preservative treatment preservative treatment, please contact us fr more information

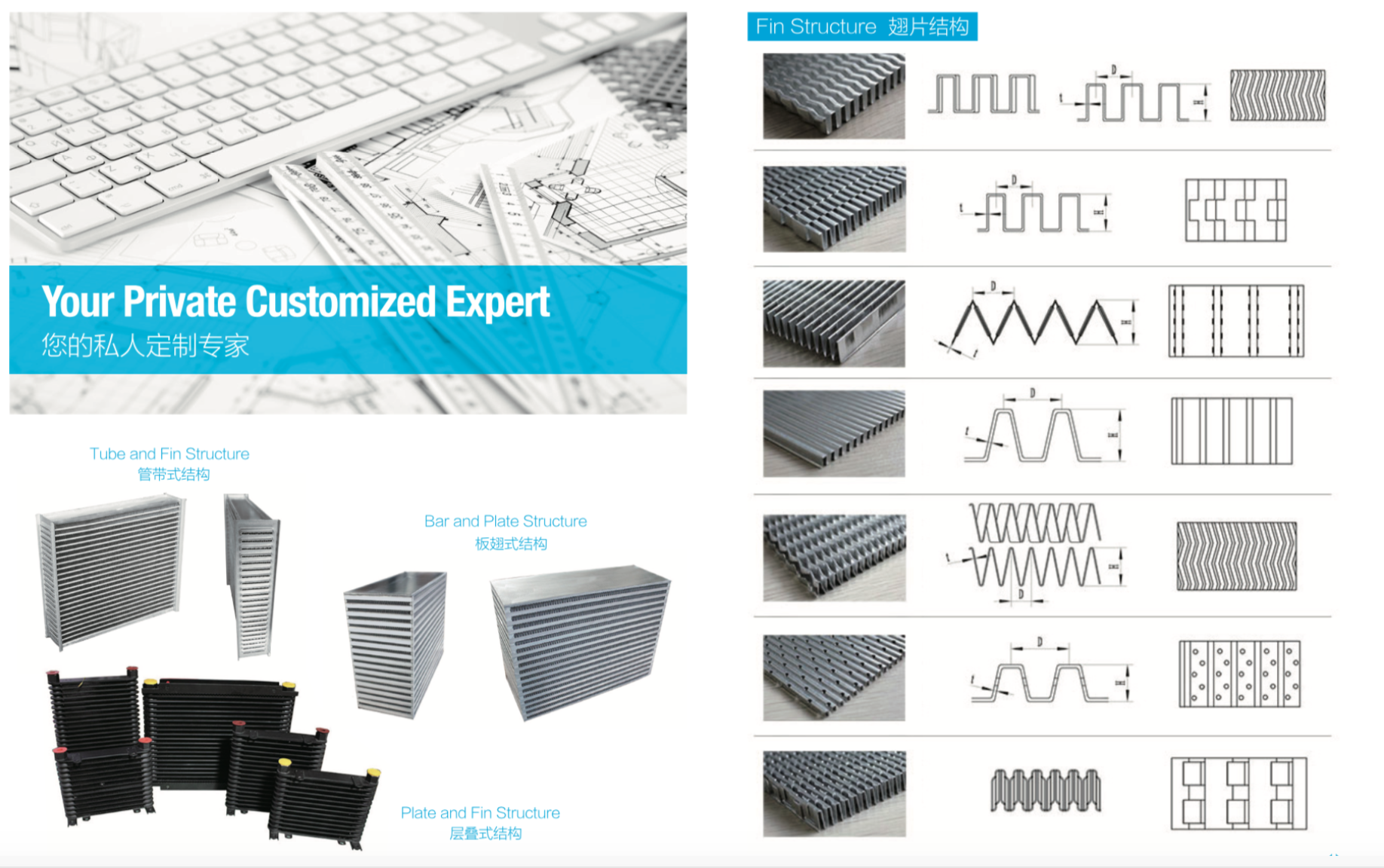

Customization Service

Compressor after cooler Custom Service Guide

You just need to tell us your specific requirements and environmental parameters for your compressor, so that we can make professional quotations accordingly.

Please advise:

| Oil parameter | Fluid | |

| Flow | ||

| Inlet temperature (℃) | ||

| Cooling power (kw) | ||

| Max. allowable pressure drop | ||

| Max. work pressure (MPa) | ||

| Air parameter | Flow | |

| Inlet temperature (℃) | ||

| Cooling power (kw) | ||

| Max. allowable pressure drop | ||

| Max. work pressure (MPa) | ||

| Cool air parameter | Flow & Pressure curve | |

| Inlet temperature (℃) | ||

| Air trace | ||

| Mounting | Max overall dimension | |

| Location of connections | ||

| Requirement of structure | ||

| Working condition | ||

Be free to contact us if you need any further information, thank you!