ShenZhen Vector Technology Co., Ltd. |

|

380V Ac Servo System Position / Speed / Torque Control For Printing Machine

Servo Drive + Servo Motor

Power Covers 200W-110KW

Single/Three Phase 220V/380V

Modbus / CanOpen / EtherCAT

Location, Speed and Torque Control Mode

2500 line incremental + Hall encoder; 2500 line incremental; 17/23

bit Tamagawa absolute encoder;

24 bit Nikon absolute encoder

Products Description

| Products | Ac Servo System |

| Brand | Vector |

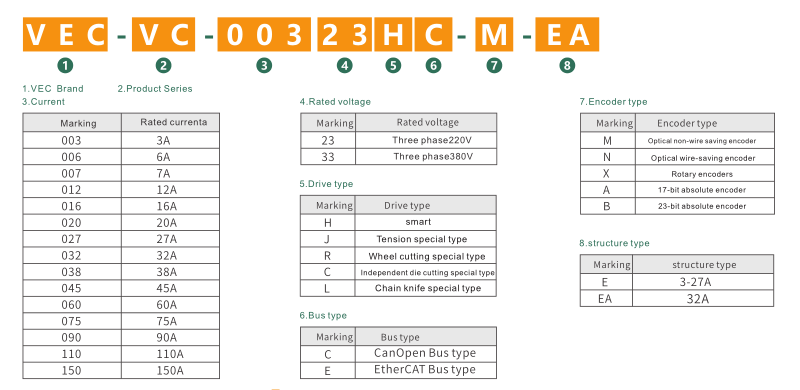

| Model No. | VEC-VC-00733HC-M-E / 130MB-00125A33F-MF2 |

| Power | 1KW |

| Voltage | 380V |

| Phase | Three Phase |

| Rated Speed | 2500 rpm |

| Rated Current | 2.6A |

| Rated Torgue | 4 Nm |

| Communication Protocols | Modbus/CANopen/EtherCAT |

| Encoder | 2500 line incremental + Hall encoder; 2500 line incremental; 17/23

bit Tamagawa absolute encoder; 24 bit Nikon absolute encoder |

How is the Servo System works? The Location control model, Speed control model and Trogue control model.

| Voltage | Control Mode | Single-phase / three-phase full-controlled rectification SVPWM modulation |

| Encoder | Encoder Feedback | 2500 pulse incremental + Hall encoder; 2500 pulse incremental; 17bit Tamagawa absolute encoder; 23bit Tamagawa absolute encoder; 24bit Nikon absolute encoder; |

| Pulse Command Input | Pulse Type | Differential input,Open collector |

| Frequency Range | Differential input:0-500kHz,pulse width greater than 1us Open collector: 0-300kHz,pulse width greater than 2.5us | |

| Pulse Mode | pulse + direction; AB pluses; CW+CCW; | |

| Analog Input | Voltage Range | -10V to 10V |

| Input Impedance | 10kΩ | |

| Maximum Frequency | 1.5kHz |

Servo Drive Description- Detaails about a Servo Drive, how to

select the Servo drive model and do installation?

● Install the driver on a dry and sturdy platform. Maintain good ventilation and

heat dissipation during installation and maintain good grounding.

● Please install in the specified direction to avoid malfunction.

● When installing, please ensure that the servo driver is kept at a specified

distance from the inner surface of the cabinet and other machines, otherwise it may cause fire or malfunction.

● Please install in the following environment:

1.places without direct sunlight;

2.Locations where the ambient temperature is in the range of 0 ° C to 55 ° C;

3.Relative humidity in the range of 0% to 95%, and no condensation;

4.Locations free of water droplets, vapors, dust and oily dust;

5.Locations where there is no high heat device;

6.Non-corrosive, flammable gas and liquid sites;

7.It is not easy to splash water, oil and medicine;

8.places that are not exposed to radioactive radiation;

9.Strong and vibration-free places;

10.Locations where there is no electromagnetic noise interference.

Accessories

| Accessory name | Image | ||

| Satandard Spare Parts | Power terminal |  | Adapt to E1,E2 structure drive |

| Cn3 encoder plug | Encoder plug on the driver side | ||

| Cn4 control terminal plug | Input/output signal terminals,user wiring | ||

| Encoder connection line | The standard cable length is 3, 5, 8, 10, 13, 15 meters, according

to customer needs Provide independent connector | ||

| Power line | The standard cable length is 3, 5, 8, 10, 13, 15 meters, according

to customer needs Provide independent connector | ||

| Drive monitoring line | Connect and adjust the software for remote monitoring and firmware update | ||

| Purchasing Spare Parts | USB to RS232 Adapter cable | If necessary, self purchase | |

| Ethernet communication line | If necessary, self purchase |

Certificates

1. CE (EU Safety Standard);

2. IEC/EN61800-5-1:2007 (Safety requirements for electrical,

thermal and energy in Section 5-1 of the variable

speed electric driver system), corresponding to the national standard GB12668.501-2013;

3, IEC / EN61800-3: 2004 + A1 (speed control electric driver system part 3 electromagnetic compatibility standards

and its specific test methods), corresponding to the national standard GB12668.3-2012.

Delivery Time and Shipping Way

| Quantity | 1-5 kits | 50-100 kits | 200-500 kits |

| Delivery time | Within 3 days | 5-10 days | 15-25 days |

1. For small order we always can delivery out within 1 week.

2. Our products can be shippied via Air, Land or Sea.