Jiangsu Sankon Building Materials Technology Co., Ltd. |

Application of ball mill machine:

The ball mill is widely applied in mineral classification, cement,

fireproof materials, glass, pottery, chemical industry and so on.

The ball mill can grind all kinds of rocks and grinding materials.

There are two ways of grinding: the dry process and the wet

process.

1. Iron ore beneficiation line

2. Copper ore beneficiation line

3. Gold ore beneficiation line

4. Lead-Zinc ore beneficiation line

5. Fluorite ore beneficiation line

6. Iron slag grinding line

7. Cement clinker grinding line

8. Graphite powder grinding line

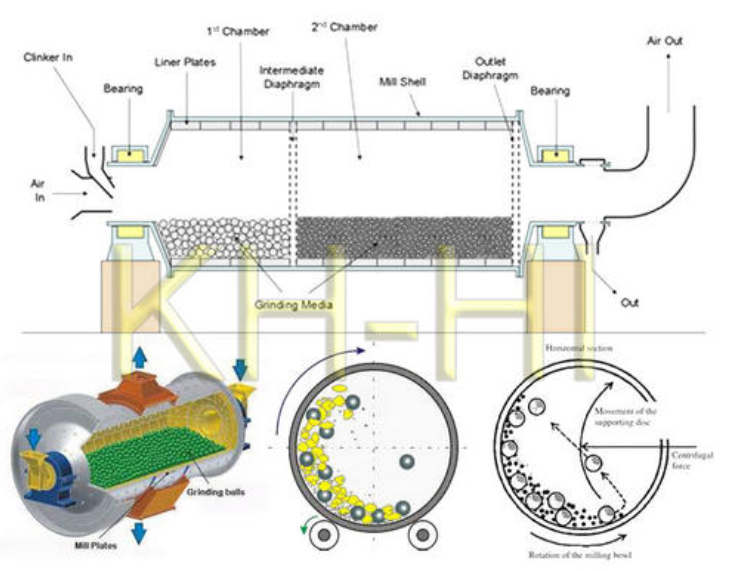

Ball mill working principle:

There are many grinding medium balls inside the continuous rotating

drum (there are many rods inside the rod mill). The continuous

feeding material is broken by the shooting balls which are coming

from a certain height of the wall of the drum; The falling medium

and material would produce irregular slip and roll during the

rotation of the drum, and the material is pulverized fine by the

grinding effect among medium, drum-lining and materials. The

dynamic material level different is produced by continuous forced

material charge and discharge, consequently more and more fine

material is slow out from the drum, and finish the grinding process

inside the drum.

| Type | Diameter of the tanks | Length of the tanks | Type of the motor | Power of the motor | Length | Width | Height | Processing power | Effective volume | Maximum ball loading | Weight |

| MQGg1212 | 1200 | 1200 | Y200L2-6 | 22 | 3512 | 2076 | 1620 | 0.17~4.1 | 1.14 | 2.4 | 9610 |

| MQGg1240 | 1200 | 4000 | JR117-8 | 80 | 7990 | 2210 | 2262 | 0.34~8.3 | 3.8 | 7.8 | 15932 |

| MQGg1515 | 1500 | 1500 | Y280M-8 | 45 | 5740 | 3075 | 2280 | 1.4~4.5 | 2.2 | 5 | 17125 |

| MQGg1545 | 1500 | 4500 | JR127-8 | 130 | 9680 | 3254 | 2370 | 3.5~12.5 | 7 | 12 | 27346 |

| MQGg1830 | 1800 | 3000 | JR136-8 | 180 | 8250 | 3620 | 2785 | 4.5~27 | 6.65 | 14 | 31850 |

| MQGg1870 | 1800 | 7020 | JR138-8 | 245 | 12404 | 3783 | 2735 | 7~50 | 15 | 31.5 | 45166 |

| MQGg2122 | 2100 | 3000 | JR128-8 | 155 | 7135 | 4137.7 | 3083 | 5~29 | 6.6 | 20 | 38340 |

| MQGg2140 | 2100 | 4000 | JR137-8 | 210 | 9654 | 4320 | 3083 | 7.5~45 | 12.8 | 22.5 | 47262.4 |

Ball mill structure:

The machine is composed of feeding part, discharging part, turning

part and driving part (reducer, small driving gear, electric motor

and electric control). The quill shaft adopts cast steel part and

the liner is detachable. The turning gearwheel adopts casting

hobbing process and the drum is equipped with wear-resistant liner,

which has good wear-resistance. The machine is with stable and

reliable working condition. Moreover, according to different

materials and discharging methods, there are dry ball mills and wet

ball mills for choice.

Ball mill parts introduce:

1. Ball mill bearing: China TOP3 brand. Wafangdian, Luoyang brand,

Ha'erbin brand

2. Liner: Manganese alloy. We can show you the material

certificate.

3. Shell: Q235, thicknesses reach the industry standard.

4. Motor: China first line brand, also we can adopt Siemens and

others.

Packing & Shipping:

Package conforms to the requirements of customs.

After-sales service:

1.Provide engineers abroad installation and commissioning service.

2.Held online or site training for workers to ensure the safe

operation.

3.Our expert will answer any inquiry within 24-48 hours and it will be solved as soon as possible.

4.We supplies the complete technical documents and the relative drawings of the electric components which were written in Chinese and English.

5.Service is available lifelong.