Jiangsu Sankon Building Materials Technology Co., Ltd. |

|

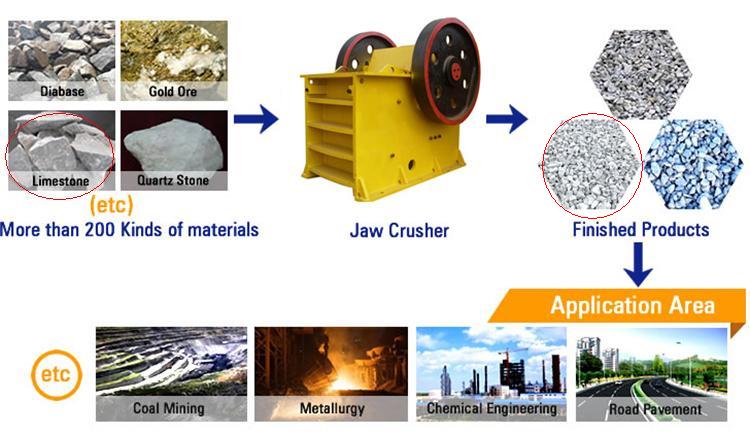

Semi Automatic AAC Panel Production Line-Jaw crusher

Description:

The JC series jaw crusher machine is a new type of jaw crusher with optimized and developed design on structure, material selection, manufacture process and assembly, which is based on absorbing the international advanced technology and applying our company's decades design concept and technology of jaw crusher. With the feature of smart structure and excellent performance, the machine is suitable for crushing all kinds of hard and abrasive rock and mineral ore. In order to meet the needs of different working conditions from the customers, this machine can apply modular bolt connecting frame without welding.

| Main technical parameter | |

| Name | Jaw Crusher Machine |

| Molding cycle | 1~3MONTHS |

| Type | CUSTOMIZED |

| Rated voltage | 380V |

| Certificate | ISO9001/CE |

| Factory Area | 48744㎡ |

Features:

STRONG STRUCTURE:

There are two types of frame for JC Jaw Crusher: welded frame and

modular bolt connecting frame. Generally we apply the welded frame

for the small and medium-sized jaw crusher and the modular bolt

connecting frame for the large-sized jaw crusher. The welding

method for the welded frame greatly reduces the stress

concentration to ensure the equal strength of the frame in

different directions. They have the features of impact resistance,

even force and low failure rate, etc. The modular bolt connecting

frame has the features of fatigue strength and high reliability.

The non-welded method for the modular bolt connecting frame is very

convenient for transportation and installation, especially suitable

for the underground mine, high altitude mine and other places which

are narrow or difficult for transportation.

OPTIMAL DESIGN OF CRUSHING CHAMBER:

Applying the V-type symmetrical design of crushing chamber, the

actual width of the feeding opening is consistent with its nominal

width. Also with the deep crushing chamer, tight nip angle and long

stroke, the machine has lower energy consumption and better

processing capacity and crushing performance.

SWING JAW ASSEMBLY:

The swing jaw assembly consists of forged eccentric shaft,

high-duty rolling bearings and the swing jaw optimized by FEM

analysis, which ensure the impact resistance and stability of swing

jaw assembly. By using the labyrinth seal and centrailized

lubrication system, there ensure no pollution to the bearing grease

and convenient lubrication, also ensure long operating time and

good stability.

PROTECTOR PLATE OF SWING JAW:

The protector plate installed on the swing jaw reduces the impact

force from materials, which effectively protect the swing jaw and

bearings inside.

QUICK AND CONVENIENT CSS ADJUSTMENT:

The JC Series Jaw Crusher applies mechanical or hydraulic discharge

asjusting device for CSS. Compared with gasket adjustment, its

double wedge adjustment is simple, safe and fast. It can also

reduce the downtime.

BEARING:

The special bearing design ensures the big loading capacity, long

service life and reliable operating.

ROD SPRING OR HYDRAULIC CYLINDER:

Eigher the hydraulic cylinder or rod spring will be used for swing

jaw tension device. The rod spring applies advanced friction

reducing devices which can make easy and qucik adjustment.

INTEGRAL BEARING HOUSE:

The integral casting bearing structure ensures the perfect match

with the main frame, which avoids the unnecessary radial load to

the bearings during the fastening process of integral bearing

house. This makes bearing running more smoothly.

INTEGRATED MOTOR DESIGN:

The integrated design of the motor base together with the main

frame not only saves the installation space of jaw crusher, but

also reduce the length of the V-belt. As a result of synchronized

motion of the frame, motor base and motor, adjustable motor base

realize V-belt tension adjustment, increase the life time of the

V-belt.

RUBBER DAMPING DEVICE:

The special rubber damping device effectively absorbs the equipment

vibration. Meanwhile it allows crusher vertical and longitudinal

displacement, which reduces the impact to the foundation base.