Shaanxi Zhongtuo Mine Equipment Co.,Ltd |

|

Verified Suppliers

|

|

Portable Electric Borehole Drilling Rig for Quarry

Description of Electric Borehole Drilling Rig

The essence of down-the-hole rock drilling is to make the impactor dive into the hole during the rock drilling process to reduce the energy loss caused by the impact energy transmitted by the drill rod, thereby reducing the influence of the hole depth on the rock drilling efficiency.

Technical Parameters of Pneumatic Hydraulic DTH Drilling

| Model | ZTD70 | ZTQ70 | ZTD100 | ZTQ100 | |

| Drilling Diameter | 50-90mm | 50-90mm | 90-130mm | 90-130mm | |

| Drilling Depth | ≤15m | ≤15m | ≤25m | ≤25m | |

| Working Pressure | 0.5-0.7Mp | 0.5-0.7Mp | 0.5-1Mp | 0.5-1Mp | |

| Rotation Speed | 110r/m | 110r/m | 110r/m | 110-160r/m | |

| Drilling Pipe | Diameter | 42mm | 42mm | 50-60mm | 50-60mm |

| Length | 1025mm | 1025mm | 1025mm | 1025mm | |

| Size | 1740*260*420mm | 1740*260*420mm | 2280*400*550mm | 2280*380*550mm | |

Working Description of Electric Borehole Drilling Rig for Quarry

The DTH rock drilling rig is to make the impactor dive into the hole during the rock drilling process to reduce the energy loss caused by the impact energy transmitted by the drill rod, thereby reducing the impact of the hole depth on the rock drilling efficiency.

Features of Electric Borehole Drilling Rig for Quarry

1. Drilling machine full hydraulic drive, easy operation and

flexible, easy to shift, good mobility, saving time and effort;

2. Drill rotator with dual hydraulic motor drive, the output

torque, greatly improving the drilling rig rigidity;

3. The new angle mechanism makes the hole more convenient, adjusts

the scope larger, can reduce the requirements of the face;

4. With a dedicated drill pipe with a drill (drill pipe, sleeve,

eccentric drill, etc.), in the unstable formation with casing wall

openings, conventional ball teeth drill hole;

5. The rig can be directly connected to the hydraulic station, the

structure is simple; the hydraulic station frame is equipped with a

roller, which is easy to move and relocate. The engine is composed

of three parts: a host, a hydraulic station, and a console.

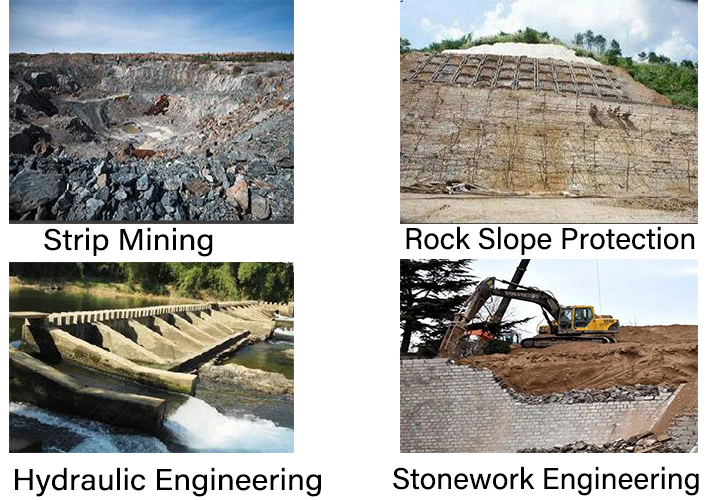

Application of Electric Borehole Drilling Rig

The Hydraulic DTH Rock Drilling Rig Machine is a submersible

electric rotary drilling rig, which is an ideal hole-forming

machine for drilling cast-in-place piles. It can also be used in

the construction of underground diaphragm walls and anti-seepage

curtains for shafts.

It is suitable for drilling in various formations such as silt,

clay, gravel layer, and weathered shale. It is widely used in the

basic construction of industrial and civil construction and other

projects.

DTH drilling rig is mainly used for drilling blasting holes in

open-pit mines, and can also be used for open-pit drilling

operations in construction, water conservancy, electric power

engineering, highway, railway, and military engineering. It is the

main perforating equipment for small and medium-sized open pit

mines.

Daily maintenance of Electric Borehole Drilling Rig

1. Wipe the outer surface of the DTH drilling rig clean, and pay attention to the cleaning and good lubrication of the surfaces such as the slideway of the base of the DTH drilling rig and the vertical shaft.

2. Check whether all exposed bolts, nuts, safety pins, etc. are firm and reliable.

3. Add lubricating oil or grease according to lubrication requirements.

4. Remove the dirt and mud on the tooth surface of the chuck and slip.

5. Clean up the oil and mud on the inner surface of the brake.

6. Clean the filter in the oil tank and replace the deteriorated or dirty hydraulic oil.

7. Check the integrity of the main components, if damaged, replace them in time, and do not work with injuries.