Henan Zhengzhou Mining Machinery CO.Ltd |

|

Verified Suppliers

|

|

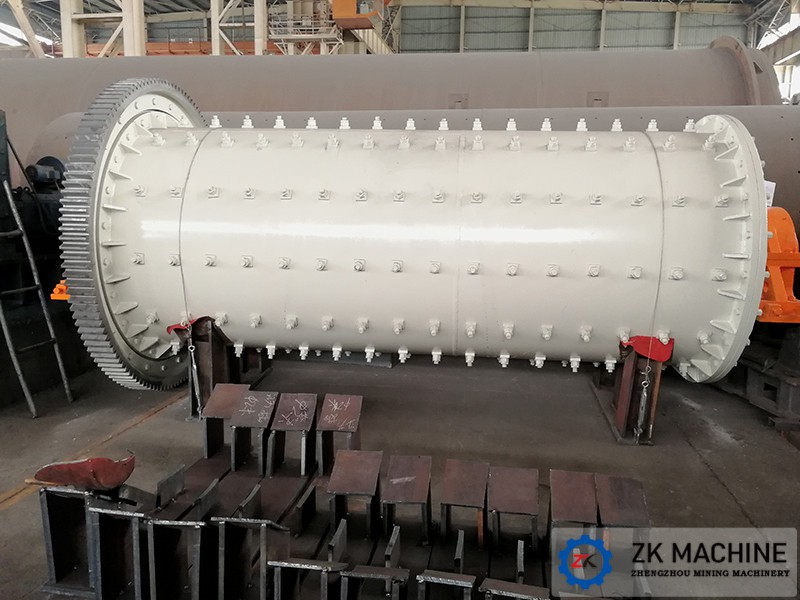

High Efficiency Gypsum Ball Mill Energy Saving For Preparation Of Phosphogypsum Powder

Gypsum Ball Mill Description

The phosphogypsum ball mill is improved on the basis of the general-purpose ball mill. After phosphogypsum is dehydrated and calcined, it often needs to be ground into building gypsum powder before it can be used as a building material to make blocks and boards. The phosphogypsum ball mill is a special mill developed by our company based on the performance of phosphogypsum and combined with a series of advantages such as energy-saving ball mills. This machine has the characteristics of energy saving, high efficiency and low pollution in the production of phosphogypsum grinding.

According to the phosphogypsum material particle size and grindability data, it focuses on the grinding characteristics and weakens the crushing performance. In the process of phosphogypsum grinding, a proper proportion of lime and other catalysts can be added to realize the modification of phosphogypsum.

Application

Used in the preparation of phosphogypsum powder by grinding.

Features

1. The phosphogypsum ball mill is highly adaptable: according to the industrial use of building phosphogypsum powder, it can grind products with different fineness suitable for various purposes such as gypsum blocks, gypsum mortar, etc., with high adaptability and stable output;

2. Energy consumption of phosphogypsum ball mill equipment: Compared with other materials, phosphogypsum has high output and low power consumption due to its small particle size and good grindability;

3. The maturity and reliability of phosphogypsum ball mill equipment. The grinding technology of the ball mill is mature and universal, and the grinding characteristics in the production process are optimized, and the operation is stable and reliable, and avoids various shutdown and downtime risks caused by immature technology after it is put into production;

4. During the grinding process of the phosphogypsum ball mill, other production processes can be added, such as a proper amount of lime or other additives to achieve the performance of phosphogypsum and optimize the strength.

Gypsum Ball Mill Specifications

| Specification (m) | Capacity (t/h) | Rotating speed (r/min) | Grinding body (t) | Motor | Reducer | Weight (t) | ||

|---|---|---|---|---|---|---|---|---|

| Model | Power (kW) | Model | Speed ratio | |||||

| Φ1.2x4.5 | 1.4 | 30.3 | 5 | YR250M-6 | 55 | ZD30-8 | 4.481 | 13.1 |

| Φ1.5x5.7 | 3.5 | 26.34 | 11 | JR127-8 | 130 | ZD40-7 | 4 | 25 |

| Φ1.83x6.4 | 6 | 23.9 | 18 | JR137-8 | 210 | ZD60-8 | 4.5 | 35.3 |

| Φ1.83x7 | 6.5 | 24.5 | 20 | JR138-8 | 245 | ZD60-8 | 4.5 | 37.2 |

| Φ2x9 | 9.5-10 | 23.88 | 31 | JR158-8 | 380 | ZD70-8 | 4.5 | 58.4 |

| Φ2.2x6.5 | 11 | 21.4 | 30 | JRQ158-8/YR630-8 | 380 | ZD70-9 | 5 | 46.2 |

| Φ2.2x6.5 | 14 Closed circuit | 21.4 | 30 | JRQ158-8/YR630-8 | 380 | ZD70-9 | 5 | 46.2 |

| Φ2.2x7 | 12 | 21.4 | 30 | JR158-8 | 380 | ZD70-9 | 5 | 54 |

| Φ2.2x7.5 | 13 | 21.4 | 32 | JR158-8 | 380 | ZD70-9 | 5 | 63 |

| Φ2.2x8 | 14 | 21.4 | 37 | JR158-8 | 380 | ZD70-9 | 5 | 65 |

| Φ2.2x9.5 | 14-16 Closed circuit | 21.4 | 43 | JR1510-8 | 475 | ZD70-9 | 5 | 70 |

| Φ2.2x13 | 16 | 20.3 | 55 | YR630-8/1180/Y100L-8 | 630/11 | JD630/ZS82.5-7 | 6.3/99.96 | 114.4 |

| Φ2.4x7 | 14-16 Closed circuit | 20.4 | 36 | JR1510-8 | 475 | JDX450 | 5 | 67.9 |

| Φ2.4x8 | 16-17 Closed circuit | 20.3 | 41 | JR1512-8/Y180L-8 | 570/11 | JD630/ZS82.5-7 | 6.333/99.96 | 87.2 |

| Φ2.4x9 | 17-19 Closed circuit | 20.3 | 46 | YR630-8/1180/Y100L-8 | 630/11 | JD630/ZS82.5-7 | 6.333/99.96 | 93.5 |

| Φ2.4x10 | 18-19 Open circuit | 20.3 | 50 | YR630-8/1180/Y100L-8 | 630/11 | JD630/ZS82.5-7 | 6.333/99.96 | 99.4 |

| Φ2.4x11 | 19-21 Open circuit | 20.3 | 60 | YR630-8/1180/Y100L-8 | 630/11 | JD630/ZS82.5-7 | 6.333/99.96 | 99.4 |

| Φ2.4x12 | 25-27 Closed circuit | 20.3 | 61 | YR800-8/1180/Y100L-8 | 800/11 | JD630/ZS82.5-7 | 6.333/99.96 | 112.7 |

| Φ2.4x13 | 25-27 High fine open circuit | 20.3 | 66 | YR800-8/1180/Y100L-8 | 800/11 | JD630/ZS82.5-7 | 6.333/99.96 | 131.1 |

| Φ2.4x13 | 21-23 Open circuit | 20.3 | 66 | YR1000-8/1180/Y160M-4 | 1000/11 | JD630/ZS82.5-7 | 6.333/99.96 | 130.4 |

| Φ2.6x10 | 25-27 Closed circuit | 20.3 | 60 | YR800-8/1250 | 800 | JD800 | 5.5 | 150.5 |

| Φ2.6x13 | 27-29 | 19.1 | 80 | YR1000-8/1180/Y160M-4 | 1000/11 | 5.5/280 | 169 | |

| Φ3x9 | 33-34 Closed circuit | 19.6 | 79 | YR1000-8/1180/Y160M-4 | 1000/11 | NAL108/8/ZS110-19 | 8/280 | 156.5 |

| Φ3x11 | 35-40 Closed circuit | 18.3 | 97 | YR1250-8/1430/YR160M-4 | 1250/11 | YNL1210 | 6.3 | 178 |

| Φ3x11 | 47 Closed circuit | 17.7 | 97 | YR118/74-8 | 1250 | ZI314 | 42.39 | 169 |

| Φ3x12 | 38-40 Closed circuit | 18.1 | 90 | YR1250-8/1430 | 1250/11 | JS1100-00 | 41.27 | 196.26 |

| Φ3.2x11 | 40 Closed circuit | 18 | 103 | YR1400-8/1430/Y160M-4 | 1400/11 | YNL1210/ZS110-19 | 12.35/28 | 186.1 Without motor |

| Φ3.5x11.5 | 65-70 Closed circuit | 16.5 | 129 | TYD143/49-8 | 2000 | ZI370 | 36.239 | 138.3 Without motor |

| Φ3.5x11.5 | 50 Closed circuit | 17.2 | 126 | YR1800-8/1430/Y200L2-2 | 1800/37 | 43.02/318 | 252.27 | |

| Φ3.8x13 Double slipper | 70-75 Closed circuit | 16.6 | 170 | YRKK800-8 | 2500 | JS130/MFY250 | 44.9 | 203 Without motor |

| Φ3.8x13 | 60-62 | 16.3 | 170 | YR2500-10/1730 | 2500 | MFYX250 | 286 | |

| Φ4x13 | 65 Closed circuit | 15.95 | 202 | YRKK900-8 | 2800 | JS130-8 | 46.7 | 264 |

| Φ4.2x13 | 85 Closed circuit | 16.3 | 224 | YRKK900-8 | 3150 | MFY320 | 47.8 | 250 Without motor |

| Φ4.2x13 | 85-87 | 16.3 | 224 | YR1000-8 | 3530 | JQS3550 | 15.6 | 254 Without motor |

About Us

Henan Zhengzhou Mining Machinery Co., Ltd (hereinafter referred to as “Henan ZK Corp”)., founded in 1956.

After more than 60 years of development, it has gradually developed from a single mechanical equipment manufacturing enterprise into a high-tech enterprise which is integrating scientific research, engineering, manufacturing, installation, commissioning and operation guarantee, with a net asset of more than US$29 million.