Fangyu(shanghai)Automation Technology Co.,Ltd |

|

Welding robotic work station Robot workcell For Welding Tricycle, Bicycle, Bike, Frame

NUMBER OF AXES | 6 |

PAYLOAD | 12 kg |

MAX. WORKING RANGE | 2,010 mm |

REPEATABILITY | 0.03 mm |

WEIGHT | 260 kg |

POWER SUPPLY | 2 kVA |

MOUNTING OPTIONS | Ceiling, Wall, Floor |

Welding robot workcell

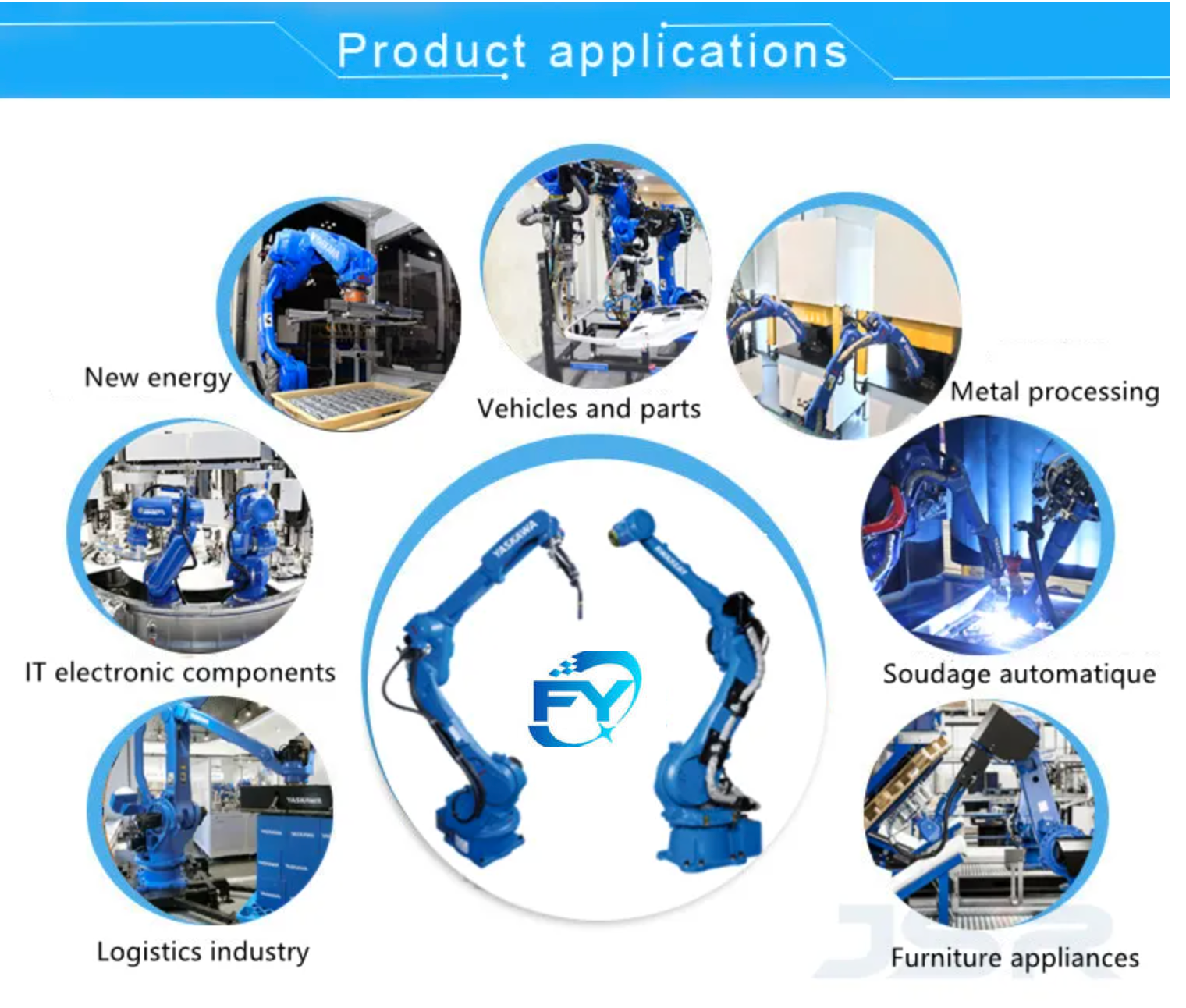

Welding robot workcell can be used in manufacturing, installation, testing, logistics and other production links, and are widely used in automotive vehicles and auto parts, construction machinery, rail transit, low-voltage electrical appliances, electricity, IC equipment, military industry, tobacco, finance, medicine, Metallurgy, printing and publishing industries have a wide range of applications. It not only facilitates corporate supervision, saves costs, but also guarantees welding quality, stable efficiency, and high safety performance. It is the choice of a wide range of users.

Shanghai FangYu Welding Technology Co., Ltd. is a comprehensive high-tech enterprise specializing in the research and development, production, and marketing of equipment and materials in the fields of industrial robots, welding and cutting, and providing comprehensive technical services. The company's main products: Yaskawa robots, Panasonic robots, spot welding robots, arc welding robots, Panasonic welding machines, OTC welding machines, aluminum welding wires, welding equipment accessories, etc.

Products are widely used in arc welding, spot welding, gluing,

cutting, handling, palletizing, painting, scientific research and

teaching. Provide automation equipment design, installation and

manufacturing services for many auto parts manufacturers.

Company strategy: Provide Chinese automation solutions for global

customers

Our philosophy: Become a high-quality supplier of robotic

automation equipment;

Our value: Competitive team, pioneering and enterprising,

continuous innovation, and the courage to challenge;

Our mission: We provide customers with high-quality products and

high-quality services;

Our technology: Supported by a senior technical team;