Anhui Herrman Machinery Technology Co.,ltd |

|

630 Type Rigid Stranding Machine for copper wire and aluminum wire

1.Application

The machine is mainly used for stranding and compacting of copper or aluminum sector or round conductor, as well as pre-spiral sector conductor etc.

The whole machine is driven by separate motors, and each cage or capstan is driven by separate motor to drive the cage rotating by large modulus timing belt. Compared with the ground shaft transmission, the separate motor transmission leaves out the speed change gearbox and ground shaft transmission system, and solves the oil leakage and the noise problem fundamentally. It makes the maintenance more convenient. The ground shaft and transmission gear have been cancelled, so the transmission energy consumption reduces. The energy consumption of separate motor transmission is less than that in the ground shaft transmission in machine normal running.

2.Main technical specification:

3.1 Diameter of single wire Al: Φ1.8-Φ5.0mm

Cu:Φ1.5-Φ5.0mm

3.2 Max. Stranding OD Φ45mm

3.3 Max. Rotating speed (with full loading)

12B 170rpm

18B 150rpm

24B 132rpm

3.4 Stranding pitch (can be set on touch screen)

12B 45~602mm (non-stage)

18B 49~685mm (non-stage)

24B 56~877mm (non-stage)

3.5 Motor power of each cage

12B 90KW (AC variable frequency motor)

18B 90KW (AC variable frequency motor)

24B 90KW (AC variable frequency motor)

3.6 Meter counter (mechanical & electrical)

3.6.1 Circumference length of the meter counter πD=500mm

3.6.2 Meter counting precision error ±0.3%

3.6.3 Max. Counting length 9999.9m

3.7 Φ2000 Strong dual haul-off capstan (with pneumatic wire pressing device)

3.7.1 Capstan diameter Φ2000 (groove:5,6)

3.7.2 Max. Haul-off linear speed 40m/min

3.7.3 Max. Haul-off force 12t

3.7.4 Motor power 90KW(AC variable frequency motor)

3.8 Φ3150 Column type take-up with traversing stand

3.8.1 Loading weight 12t

3.8.2 Take-up bobbin PN1600~PN3150mm

3.8.3 Max. Traverse diameter Φ60mm

3.8.4 Max. T/U speed 50m/min

3.9 Line central height 1000mm

3.Main parts

2.1 12 &18,24 stranding cage each 1 set

2.2 Pre-twist & compacting device 3 sets

2.3 Side-bottom loading device 3 sets

2.4 Φ2000 Strong dual haul-off capstan 1 set

2.5 Meter counter (mechanical & electrical ) 1 set

2.6 Φ3150 Column type take-up with traversing stand 1 set

2.7 Electrical control system 1 set

2.8 Safety protection system 1 set

4.Relevant Photos

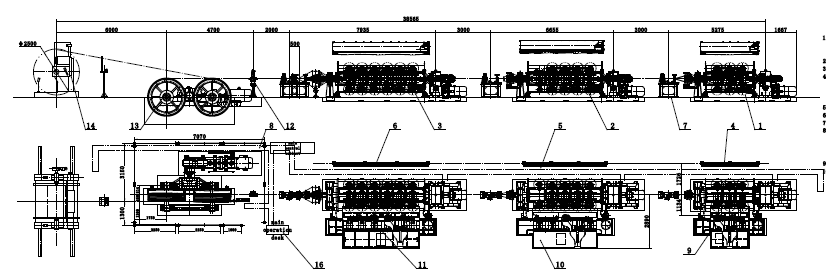

5.Drawing