Hebei Junke Machinery Technology Co.,Ltd |

|

Verified Suppliers

|

|

1, hoist and tower crane in vertical transport machinery in the scope of application can be used together; There's no limit.

2, the scope of application of hoist and tower crane (characteristics) is different

Construction technology is not too complex, components can be zero points of the case, can use winch (such as brick structure). If large components cannot be separated, tower cranes shall be used (such as large steel molds must be used for cast-in-place cement shear wall structure).

Tower crane: large working space, light weight, small section, small wind resistance, high and falling tower safety problems, easy to operate, comfortable. The most important thing is that the operator is convenient, commanding, crystal clear, thus greatly improving the safety line, is the first choice for construction ~

The wire ropes on the crane drum should be arranged neatly. If overlap and oblique winding are found, they should be stopped and rearranged. It is forbidden to pull the wire rope by hand or foot in rotation. The wire rope shall not be completely released, at least three laps shall be reserved.

2, crane wire rope is not allowed to knot, twist, in a pitch break more than 10%, should be replaced.

3. In the crane operation, no one shall cross the wire rope, and the operator shall not leave the hoist after the object (object) is lifted. Objects or cages should be lowered to the ground when resting.

4. In the operation, the driver and signalman should maintain good visibility with the lifting object. The driver and signalman should cooperate closely and obey the unified command of the signal.

5. In case of power failure during crane operation, the power supply should be cut off and the lifting object should be lowered to the ground.

6, work to listen to the signal of the commander, the signal is unknown or may cause accidents

The operation should be suspended and the operation can be continued until the situation is clear.

7. In case of sudden power failure during crane operation, the brake knife should be opened immediately to put down the goods.

8. After the operation is completed, the material tray should be landed and the electric box should be locked.

9, crane wire rope in the process of use and mechanical wear. Spontaneous combustion corrosion of local damage is unavoidable, should be intervals coated with protective oil.

10. Overloading is strictly prohibited. That is, more than the maximum carrying tonnage.

This system is still the most effective and perfect method to prolong the life of wire rope. Tests have shown that the use with Wire rope specifications match the rope groove, Lebus drum can prolong the life of wire rope more than 500%.

LBS rope groove makes the load evenly distributed between layers, and the practice proves that it greatly prolongs the life of wire rope. In fact, the test surface can extend wire rope life by more than 500%. Reducing wire rope damage increases safety and reduces machine downtime.

Generally, the tighter the wire rope is, the better it is wound. The wire rope should withstand at least 2% of the breaking load or 10% of the operating load as recommended by LeBus. Of course, for safety factor and wire rope design, must be prepared to withstand the destructive load.

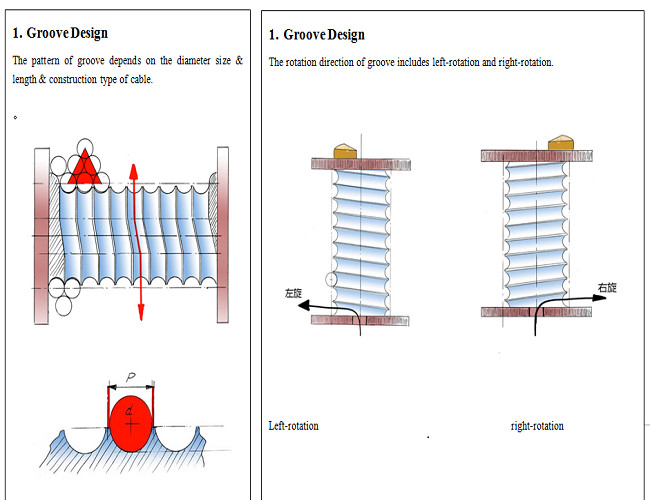

The design and manufacture of folding rope groove drum should meet the special requirements of lifting operation, and the type of rope groove should adapt to the length, diameter and structure type of wire rope. Mechanical design, machining, design software, mechanical engineer, equipment management, welding, hydraulic, casting, sealing.

Name:High Efficient Tower Crane Engineering Wire Rope Winch Drum Lebus Sleeve

Materials of the sleeves: Low-carbon steel 20#,16Mn,Q235B,Q355B/D/E

| No: | Wire diameter(mm): | Rotation direction | Main drum diameter(mm) | Main drum length(mm) | Application |

| 1 | 8 10 13 | Lefthand,Righthand | 430 | 763 | The oil workover rig winch, Towing winch Tower crane |

| 2 | 13 18 20 | Lefthand,Righthand | 623 | 1144 | Engineering winch, Lifting winch,Crawler crane |

| 3 | 22 25 26 | Lefthand,Righthand | 730 | 1220 | Oil workover rig , Logging Winch |

| 4 | 18 22 32 | Lefthand,Righthand | 670 | 1240 | Drilling Rig Winch, drawworks |

| 5 | 28 32 36 40 | Lefthand,Righthand | 560 | 630 | Rotating Drilling Rig winch, Lifting equipment |

| 6 | 26 28 32 45 | Lefthand,Righthand | 760 1146 | 1970 1765 | Offshore Crane, Marine crane,Mooring winch |