CHANGSHA SUPMETER TECHNOLOGICAL CO.,LID |

|

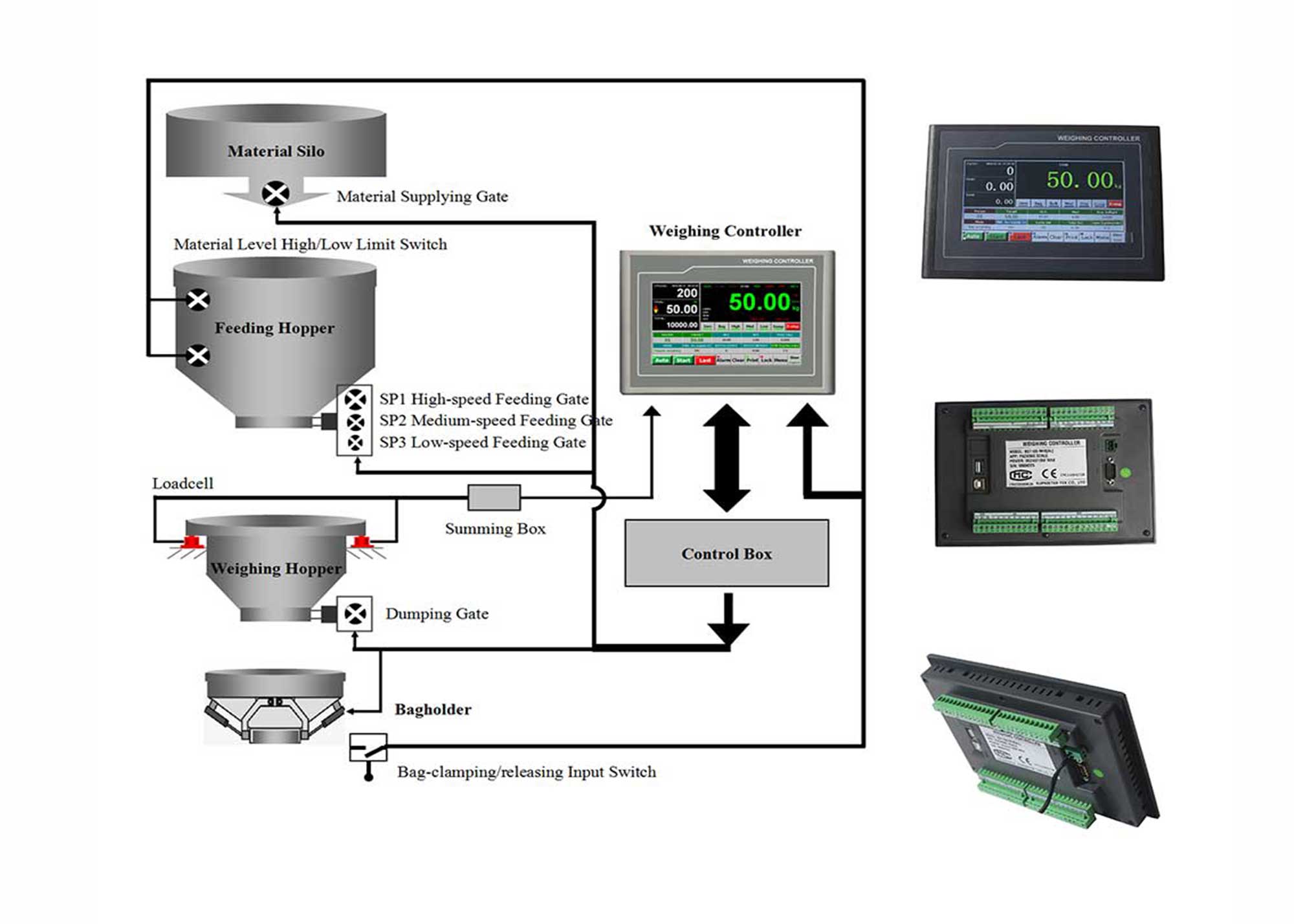

HMI Touch Screen Automatic Bagging Hopper Packaging Machine Controller BST106-M10(AL)

Main Features:

² Suitable for Ration Packing Scale with optional Hopper-weighing Mode, Bag-weighing Mode and Loss-in-weight Mode.

² EMC design with high anti-jamming capability, suitable for industrial environment.

² Cortex-A8 CPU with 600MHz Clock, 128M RAM and 128M Flash.

² 7”/10.2” Ultralight and ultrathin TFT touch screen with embedded weighing/control module.

² Loadcell Interface

l Max. Connection Quantity: 16 Loadcells (350Ω).

l 24-bit High-precision and high-speed ∑-A/D conversion module with 1/1,000,000 internal resolution and samplingfrequency 800Hz.

l Special anti-vibration digital filtering algorithm for ensuring the weighing stability and accuracy when there is strongvibration on the load receptor, and the rapid response capability when the weight signal changes.

² I/O Interface

l 9 Definable normally open switch inputs [DI] and 18 definable normally open transistor switch outputs [DO].

l Optional ‘High/Medium/Low Speed Feed’ DOs for feeding control. Optional Low-speed Feeding Modes: Continuous Feeding Mode and Inching Feeding Mode.

l 2 Definable analog signal AOs[0~10V] for weight signal output or ‘High/Medium/Low Speed Feed’ control.

² Digital Communication Interface

l COM1[RS232]&COM2[RS485] for connecting Host IPC/PLC and LED Remote Display.

l COM[RS232] for connecting RS232 Serial Printer.

l USB1 for connecting USB mouse, downloading HMI software from U-disk and copying data to U-disk.

² Software Function

l Manual Screen-locking/Screen-unlocking, Auto Screen-locking, Digital Setting&Calibration and I/O Testing functions available.

l Initial Zero Adjustment after Power-on, Auto Zero Tracking, Zero Fine Adjustment and Zero Calibrationfunctions available.

l Load Calibration and Loss Calibration functions available.

l 10 Recipes for packing control.

l Optional ‘Fall Value Auto Correction’ function.

l Optional ‘Auto Pause for Deviation Alarm’ and ‘Auto Re-feed’ functions.

l Optional ‘Target Batch Control’ function [With Target Batch Count or Target Batch Weight finished, the packing process will stop automatically].

l The Batch Records can be printed automatically.

l Historical Batch Records, Totalizing Reports and Recipes can be queried and printed.

With the multitasking mode, the weighing&control process will not be interrupted by parameter setting and the other operations.

Operation Interface of User Login

| Name | Operation | Note |

| 【Login】 | User Login. Exfactory Passwords:

| Operation ‘Main Menu / F5 User / Password / PSW Set’ for Modifying Password. |

| 【User Name】 | After password inputted, the matching User Name will be displayed. |

|

| 【Operate】 | Enter ‘Main User Interface’. | Operation ‘Main Menu / F5 User / Password / Login [Logoff]’ for Re-login and Logoff. |

Terminal Diagram

Button Operation

| Name | Operation | State Indicator | Authorization |

| 【Auto】 | Auto / Manual [Emergency Stop] switch. | Green: Auto state. Grey: Manual state. | All Users |

| 【Start】 | Start. | Green: Running state. Grey: Stop state. | |

| 【Re-run】 | Clear Alarm & Recover Running. | ||

| 【Stop】 | Normal Stop [Last Batch]. Stop after the present batch finished. | Flashing Red. | |

| 【E-Stop】 | Emergency Stop. | ||

| 【Alarm】 | Alarm Query / Clear Alarm. ‘Auto/Pause’ state: Recover Running after alarms cleared. | Red: Alarm state. | |

| 【Print】 | Report Print:

| ||

| 【Lock】 | Screen-locking: Locking/unlocking the operating buttons of main user interface. Auto Screen-locking: Refer to parameter [901]. | Flashing Red: Locked. Grey: Unlocked. | |

| 【Menu】 | Enter Main Menu. | ||

| 【User】 | User Login. Display: Operator / Engineer / Admin. | ||

| 【Zero】 | Manual Zero [No Power-down Protection]. | Flashing green. | |

| 【Bag】 | Bag-clamp/release Request. | Green: Bag-clamping state. Grey: Bag-releasing state. | |

| 【Bulk】 | Manual Start/Stop Bulk Feed. | Green: Working state. | |

| 【Med】 | Manual Start/Stop Medium Feed. | ||

| 【Drip】 | Manual Start/Stop Dribble Feed. | ||

| 【Dump】 | Manual Start/Stop Dumping. | ||

| 【Mat.】 | Manual Start/Stop Supplying Materials into Feeding Bin. | Flashing green. | |

| 【Clear】 | Clear Screen: Clear the display values of Feeding Weight, Totalized Weight, Batch Count and Cycle Speed. | Engineer Administrator |

Delivery