CHANGSHA SUPMETER TECHNOLOGICAL CO.,LID |

|

Span And Speed Calibration Belt Coveyer Lcd Display Indicator With RS232 And Accuracy Grade 0.5

| Main Menu | Second Menu | Description |

| F1 Setting | 1 Scale[Basic] | Basic scale parameters setting. |

| 1+Scale[Extra] | Extra scale parameters setting. | |

| 2 Control[Basic] | Basic feeding control parameters setting. | |

| 2+Control[Extra] | Extra feeding and batching control parameters setting. | |

| 3 Flow | Flow parameters setting. | |

| 4 Speed | Speed parameters setting. | |

| 5 Load | Load parameters setting. | |

| 6 Save/Print | Weight record parameters setting. | |

| 7 Comm. Port | Communication port parameters setting. | |

| 8 I/O | Input&output parameters setting. | |

| 9 Display | Display and operation interface parameters setting. | |

| 10 Date/Time | Date/Time parameters setting. | |

| F2 Calibration | 1 Zero Cal. | Zero Calibration without loading for correcting Zero Value. |

| 2 Span Cal. Dyn. | Dynamic Span Calibration with loading measured materials or Poise Weights for correcting Span Coefficient. | |

| 3 Span Cal.Stat1 | Static Span Calibration with a measured chain weight as a continuous and steady load on the running belt weigher for correcting Span Coefficient. | |

| 4 Span Cal.Stat2 | Static Span Calibration with a measured Hanging Weight as a steady load on the running belt weigher for correcting Span Coefficient. | |

| 5 Span Cor. Seg. | Segmenting Span Correction. After doing Dynamic or Static Span Calibration, further corrections for 3 [AD Value: 0~60000] linear segments are optional for correcting Correction Coefficient 1~3. | |

| 6 Speed Cal. | Speed Coefficient Calibration. Keep the belt weigher running at a constant speed. After the running time of a revolution being measured with using a stopwatch, do this operation for correcting Speed Coefficient. | |

| 7 Length Cal. | Belt Length Calibration. Keep the belt weigher running at a constant speed. After the running time of a revolution being measured with using a stopwatch, do this operation for correcting Belt Length. |

Suitable for Ration Belt Weighfeeder with Ration Flow Feeding &

Ration Weight Batch Control.

EMC design with high anti-jamming capability, suitable for

industrial environment.

32-bit ARM CPU with 72MHz & higher arithmetic speed.

128×64 LCD display screen with 7 background colors for English

display.

16-key English keypad.

Menu&Shortcut mode operation with key tone.

24-bit High-precision and high-speed ∑-△A/D conversion module with

1/1,000,000 internal resolution and sampling frequency 400Hz.

Broad-range speed pulse input circuit.

Special anti-vibration digital filtering algorithm for ensuring the

weighing stability and accuracy when there is strong vibration on

the load receptor, and the rapid response capability when the

weight signal changes.

Max. Connection Quantity: 8 Loadcells (350Ω).

Auto-locking, Key-locking, Key-unlocking, Digital

Setting&Calibration and I/O Testing functions available.

Auto Zero Tracking, Speed Calibration and Belt Length Calibration

functions available.

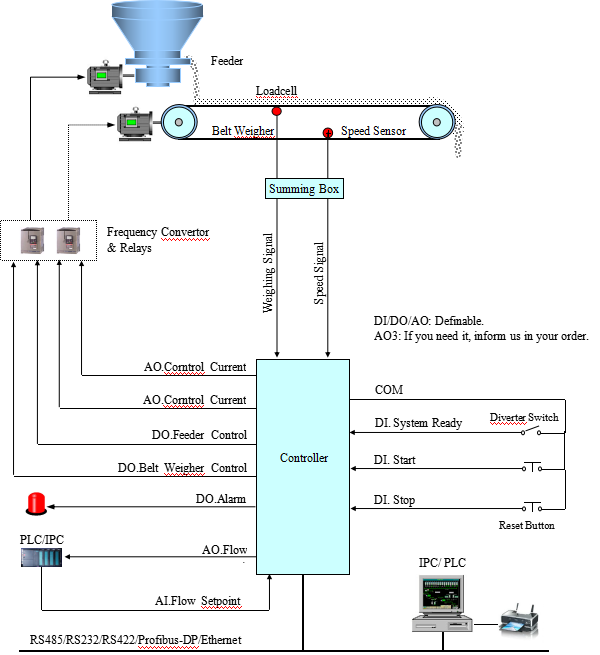

One optional 'Flow Setpoint' analog signal input [AI: 4~20mA].

Max.3 definable 'Flow/Control Current /...' analog signal outputs

[AO: 4~20mA].

Quick and steady PID ration feeding control.

3 Definable normally open switch inputs [DI] and 4 definable

normally open relay switch outputs [DO].

The feeder and belt weigher can be started and stopped by DI&DO

signal.

1 'Totalized Weight High-speed Pulse' output [PO].

2 Optional communication ports for connecting IPC/PLC, LED Remote

Display, Serial Printer and Wireless Module.

Weight Records per shift/day/month of a year can be queried and

printed.

With the multitasking mode, the weighing&control process will

not be interrupted by parameter setting and the other operations.

Main Menu | Second Menu | Description |

| F3 Weight Record | Query and print Weight Records. | |

| F4 Data Clearing | 1 Clear Screen | Clear Totalized Weight and Totalized Weight Pulse Count. But Totalized Weight of Current Shift will not be cleared, so this operation has no effect on recording of weight per shift. |

| 2 Clear Weight | Clear Totalized Weight, Totalized Weight Pulse Count and Totalized Weight of Current Shift. The cleared value of Totalized Weight of Current Shift will not be recorded. | |

| 3 Clear Records | Clear History Records of Totalized Weight. But Current Totalized Weight, Totalized Weight Pulse Count and Totalized Weight of Current Shift will not be cleared. | |

| F5 Security | 1 Auto-locking | If there is not any keypad operation in one minute and it’s not in the processes of ‘F2 Calibration’ & ‘F6 Factory Adj.’, the controller will lock the keypad and return to ‘Main Display Interface’ automatically. |

| 2 Key-locking | Locking keypad. | |

| 3 Key-unlocking | Unlocking keypad. | |

| 4 Password Set | Exfactory Password: 000001. | |

| 5 RAM Reset | Restore to factory defaults. | |

| F6 Factory Adj. | Special for manufacturer. | |

| F7 Product Info. | Only for query. | |

| 1 Version No. | Version No. | |

| 2 Serial No. | Serial No. | |

| 3 Exfactory Date | Exfactory Date. | |

| 4 Audit Counter | Audit Trail Counter [0~99999999] for Scale parameter’s modification. | |

| 5 Auth. Code | Authorization Code. | |

Ration Flow Auto-Feeding System

Delivery Time : Three days after got payment .

Main Features: