CHANGSHA SUPMETER TECHNOLOGICAL CO.,LID |

|

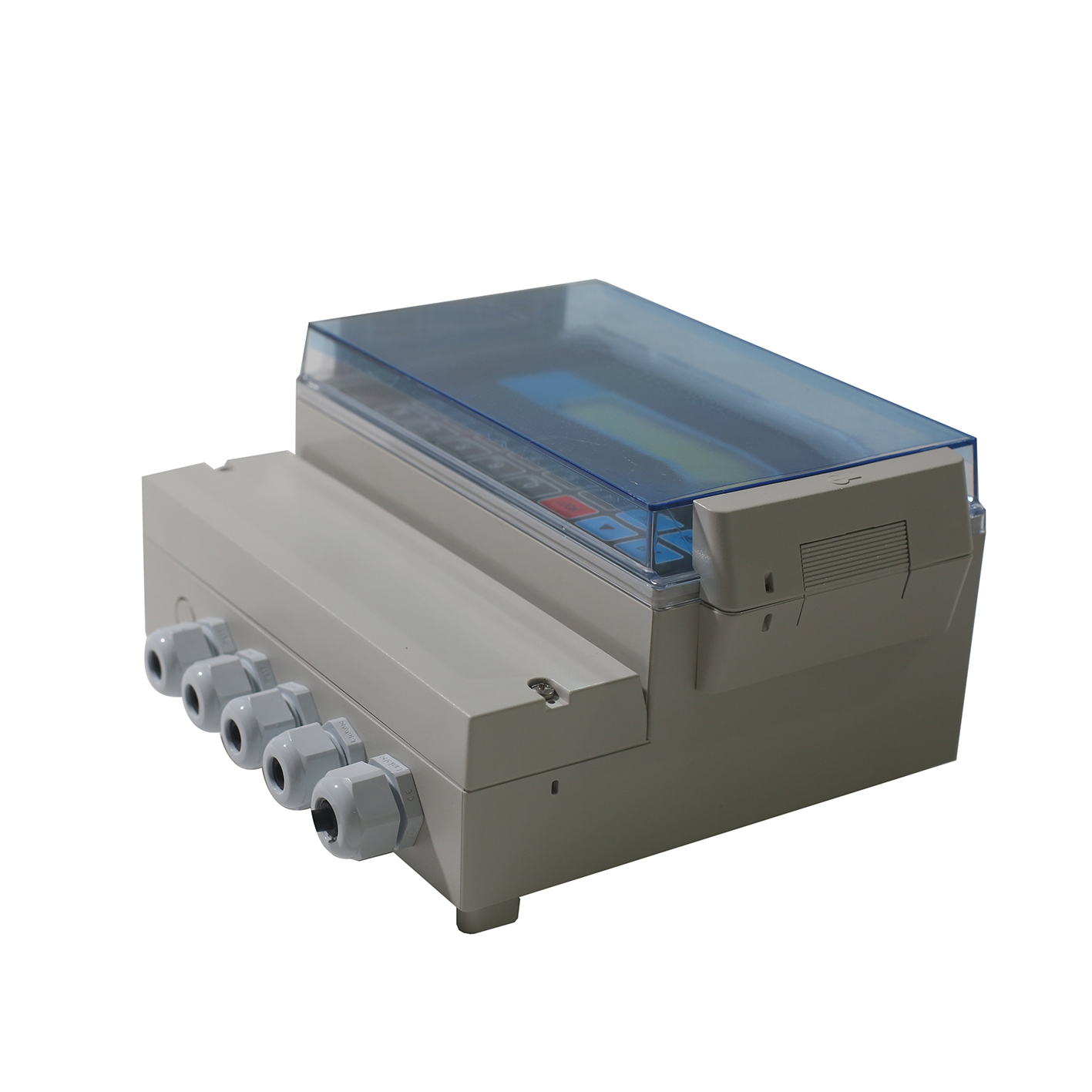

LCD Digital Belt Conveyer Scale Weighing Indicator Controller With RS232/RS485

Main Features:

Picture:

Main MENU

| Main Menu | Second Menu | Description |

| F1 Setting | 1 Scale[Basic] | Basic scale parameters setting. |

| 1+ Scale[Extra] | Extra scale parameters setting. | |

| 2 Save/Print | Weight record parameters setting. | |

| 3 Comm. Port | Communication parameters setting. | |

| 4 Display | User interface parameters setting. | |

| 5 Date/Time | Date/Time parameters setting. | |

| F2 Calibration | 1 Zero Cal. | Zero Calibration without loading for correcting Zero Value. |

| 2 Span Cal. Dyn. | Dynamic Span Calibration with loading materials or Poise Weights for correcting Span Coefficient. | |

| 3 Span Cal.Stat1 | Static Span Calibration with a measured chain weight as a continuous and steady load on the running belt weigher for correcting Span Coefficient. | |

| 4 Span Cal.Stat2 | Static Span Calibration with a measured Hanging Weight as a steady load on the running belt weigher for correcting Span Coefficient. | |

| 5 Span Cor. Seg. | Segmenting Span Correction. After doing Dynamic or Static Span Calibration, further corrections for 3 [AD Value: 0~60000] linear segments are optional for correcting Correction Coefficient 1~3. | |

| 6 Speed Cal. | Speed Coefficient Calibration. Keep the belt weigher running at a constant speed. After the running time of a revolution being measured with using a stopwatch, do this operation for correcting Speed Coefficient. | |

| 7 Length Cal. | Belt Length Calibration. Keep the belt weigher running at a constant speed. After the running time of a revolution being measured with using a stopwatch, do this operation for correcting Belt Length. |

| Main Menu | Second Menu | Description |

| F3 Weight Record | Query and print Weight Records. | |

| F4 Data Clearing | 1 Clear Screen | Clear Totalized Weight. But Totalized Weight of Current Shift will not be cleared, so this operation has no effect on recording of weight per shift. |

| 2 Clear Weight | Clear Totalized Weight and Totalized Weight of Current Shift. The cleared value of Totalized Weight of Current Shift will not be recorded. | |

| 3 Clear Records | Clear History Records of Totalized Weight. But Current Totalized Weight and Totalized Weight of Current Shift will not be cleared. | |

| F5 Security | 1 Auto-locking | If there is not any keypad operation in one minute and it’s not in the processes of ‘F2 Calibration’ & ‘F6 Factory Adj.’, the Indicator will lock the keypad and return to ‘Main Display Interface’ automatically. |

| 2 Key-locking | Locking keypad. | |

| 3 Key-unlocking | Unlocking keypad. | |

| 4 Password Set | Exfactory Password: 000001. | |

| 5 RAM Reset | Restore to factory defaults. | |

| F6 Factory Adj. | Special for manufacturer. | |

| F7 Product Info. | Only for query. | |

| 1 Version No. | Version No. | |

| 2 Serial No. | Serial No. | |

| 3 Exfactory Date | Exfactory Date. | |

| 4 Audit Counter | Audit Trail Counter [0~99999999] for Scale parameter’s modification. Only for query. | |

| 5 Auth. Code | Authorization Code. | |

Technical Specifications

Power Supply: AC220V±15%, 50/60Hz, Max. 10W.

Loadcell Excitation Voltage/Current: DC10V/250mA.

8 Loadcells[350Ω] connectable.

Weighing Signal Input Range: 0~25mV.

Speed Sensor Excitation Voltage/Current: DC12V/100mA.

Speed Signal Input Range: 0.5~3000Hz.

COM1: Optional RS232/RS485/RS422/Profibus-DP/Ethernet.

COM2: RS232.

Connect Host IPC, Remote Display, Printer&Wireless Module.

Optional 4~20mA Analog Output [AO] Module by COM1.

Outline Size [W×H×D]: 235.5 × 227.5 × 119.5 mm.

Operating Temperature: -25℃~+45℃.

Protection Level: IP65.

Accuracy Grade: 0.5.

FAQ:

1. Sample is Available?

Yes. This product support free sample. As long as you can bear the freight charge.

2. What detailed information do I need to provide if I want to place an order?

We need to know the following information: accuracy, Quantity, special requirements if you have, etc.

3. Do you have any discount?

Yes, if you buy large QTY, please send us a email, we will give you a big discount.

4. What terms of payment are available?

We accept T/T, L/C, Trade assurance, Secure payment, Western Union,etc.

5.When will you arrange the production?

We will arrange the production immediately after receiving your payment.

6. How do you ensure good product quality?

We have a complete quality control system, all of our products are fully checked by IQC, OQC departments before shipping to our clients.

7. How long is the warranty period?

The warranty period for our products is 12 (twelve) months.

If the products from SUPMETER are proved to be unable to work normally due to unartificial reasons, and the problems can't be solved by customers under the technical support from SUPMETER, then customers can send the problematic items back to SUPMETER. SUPMETER is RESPONSIBLE to MEND (or REPLACE when necessary) them FREE OF CHARGE.

(Note: if after checking, the returned goods are proved to be in good condition, the trouble is resulted to be caused by improper operation by customers, SUPMETER is IRRESPONSIBLE to bear the shipping & other charges related to the returning.)