16 Material Single Scale TFT -Touch Ration Batching Controller

TFT -Touch Ration Batching Controller 1-16 Materials [Single-scale]

Main Applications

Ration Batching Scale with 1-16 materials

[Single-scale].

Loss-in-weight Ration Mixture-dumping Control.

Main Features:

- Suitable for Ration Batching Scale with 14-Material&2-Speed

Feeding or 16-Material&1-Speed Feeding [Single-scale Mode].

- EMC design with high anti-jamming capability, suitable for

industrial environment.

- Cortex-A8 CPU with 600MHz Clock, 128M RAM and 128M Flash.

- 7”/10.2” Ultralight and ultrathin TFT touch screen with embedded

weighing/control module.

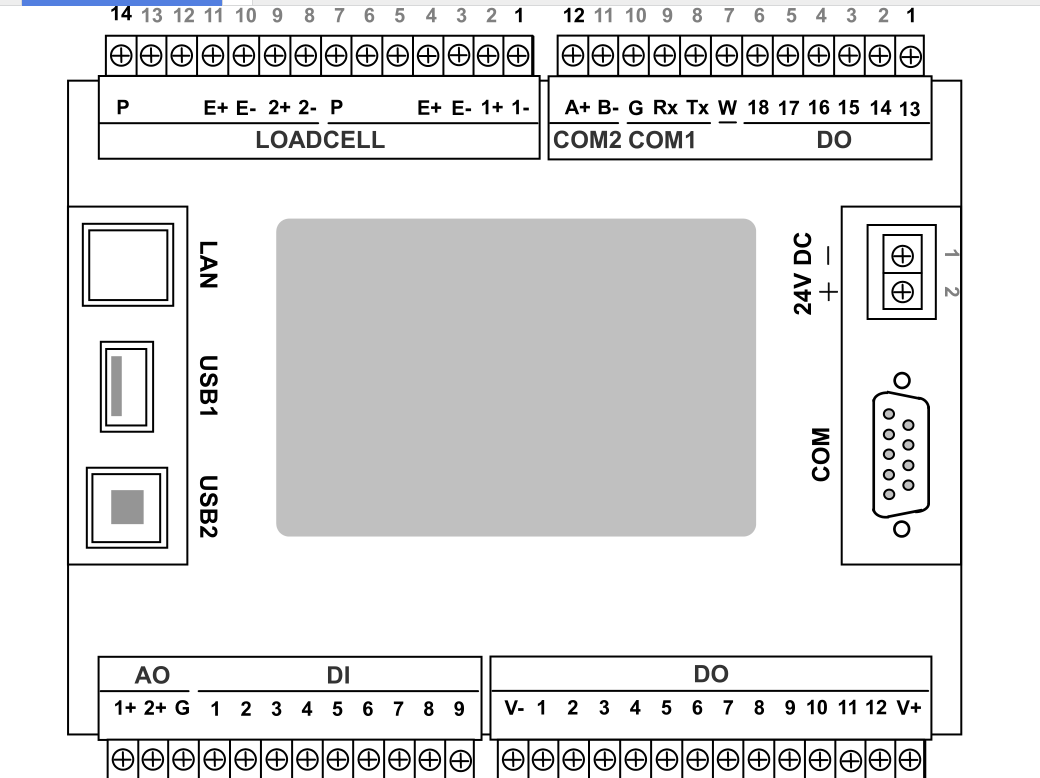

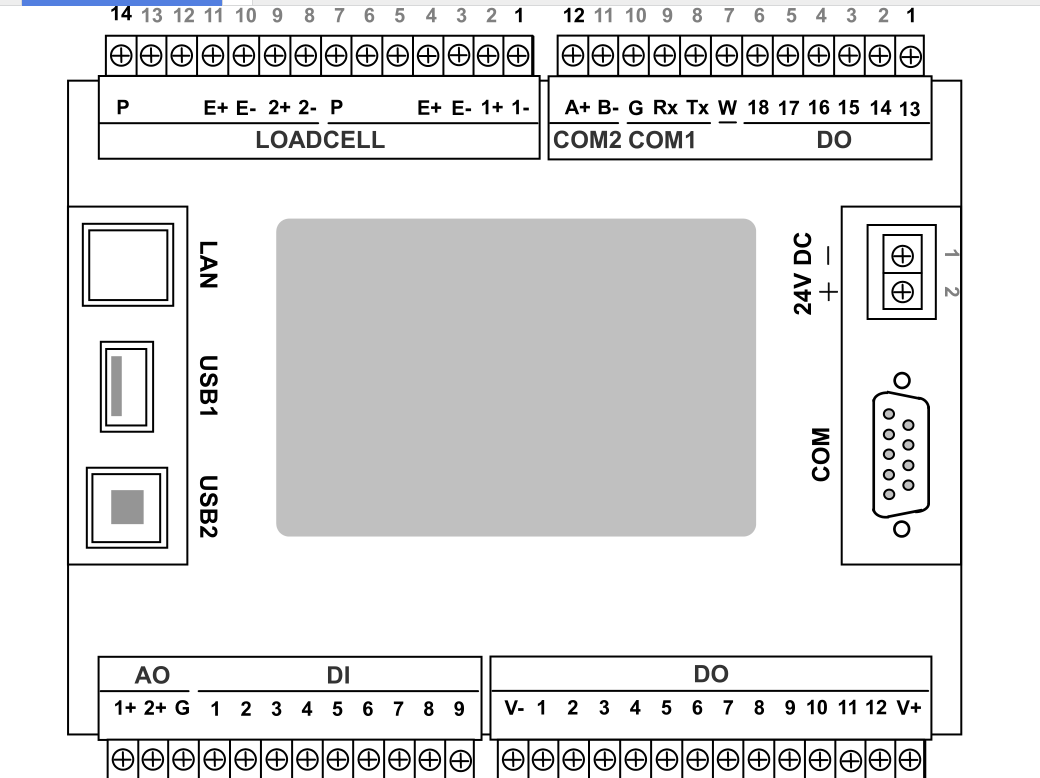

- Loadcell Interface

- Max. Connection Quantity: 16 Loadcells (350Ω).

- 24-bit High-precision and high-speed ∑-△A/D conversion module with

1/1,000,000 internal resolution and sampling frequency 800Hz.

- Special anti-vibration digital filtering algorithm for ensuring the

weighing stability and accuracy when there is strong vibration on

the load receptor, and the rapid response capability when the

weight signal changes.

- 9 Definable normally open switch inputs [DI] and 18 definable

normally open transistor switch outputs [DO].

- Optional ‘High/Low Speed Feed’ DOs for feeding control. Optional

Low-speed Feeding Modes: Continuous Feeding Mode and Inching

Feeding Mode.

- 2 Definable analog signal AO[0~10V] for weight signal output or

‘High/Low Speed Feed’ control.

- Digital Communication Interface

- COM1[RS232]&COM2[RS485] for connecting Host IPC/PLC and LED

Remote Display.

- COM[RS232] for connecting RS232 Serial Printer.

- USB1 for connecting USB mouse, downloading HMI software from U-disk

and copying data to U-disk.

- Manual Screen-locking/Screen-unlocking, Auto Screen-locking,

Digital Setting&Calibration and I/O Testing functions

available.

- Initial Zero Adjustment after Power-on, Auto Zero Tracking, Zero

Fine Adjustment and Zero Calibration functions available.

- Load Calibration and Loss Calibration functions available.

- 10 Recipes for batching control.

- Optional ‘Fall Value Auto Correction’ function.

- Optional ‘Auto Pause for Deviation Alarm’, ‘Auto Pause while Gross

Weight Upper Limit Alarming’, ‘Manual Pause’ and ‘Auto Re-feed’

functions.

- Optional ‘Target Batch Control’ function [With Target Batch Count

finished, the batching process will stop automatically].

- The Batch Records can be printed automatically.

- Historical Batch Records, Totalizing Reports and Recipes can be

queried and printed.

- With the multitasking mode, the weighing&control process will

not be interrupted by parameter setting and the other operations.

- Main Features

- EMC design with high anti-jam for industrial environment.

- DC24V power input with reverse polarity protection.

- Cortex-A8 CPU with 600MHz Clock, 128M Flash.

- 7” [800×480] or 10.2” [1024×600] TFT touch panel.

- 24-bit ∑-△ADC with internal resolution 1/1,000,000.

- High sampling frequency 800Hz.

- Special Anti-vibration Digital Filtering Algorithm for precise

- weighing, stable display and rapid response.

- Auto Zero Tracking.

- Load Calibration and Loss Calibration.

- Fall Value Auto Correction.

- Auto Re-feed for negative deviation alarm.

- Target Batch Count Control.

- Auto Pause for Gross Weight Upper Limit & Deviation Alarm.

- ‘Manual Pause’ Operation.

- 2-speed[high/low] feeding control by DOs or AOs.

- Definable DI/DO/AO/COM[Communication Port].

- Recipe Number: 100

Technical Specifications

- Power Supply: DC24V±20%, Max. 10W.

- Loadcell Excitation Voltage/Current: DC5V/250mA.

- 16 Loadcells[350Ω] connectable.

- Weighing Signal Input Range: 0~12.5mV.

- 9 Normally Open Switch Inputs [DI].

- 18 Normally Open Transistor Outputs [DO]: DC24V, 500mA.

- 2 Analog Signal Outputs [AO]: 0~10V, Max.50mA.

- COM&COM1: RS232; COM2: RS485.

- USB1: Connect mouse, software download, data backup.

- LAN: Optional Ethernet.

- Outline Size [W×H×D]

- 7”: 226.5 × 163 × 36 mm.

- 10.2”: 274 × 193 × 40 mm.

- Panel Cut-out Size [W×H]

- 7”: 215 × 152 mm.

- 10.2”: 261 × 180 mm.

- Operating Temperature: -25℃~+45℃.

- Protection Level of Front Panel: IP65.

- Accuracy Grade: III.

- Verification Accuracy: 0.02%.

- Static Weighing Accuracy: 0.2%~0.5%.

- Batching Accuracy: 0.2%~0.5%