CHANGSHA SUPMETER TECHNOLOGICAL CO.,LID |

|

Loss In Weight Weigh Feeder Controller Belt Speed Sensor With Ration Flow Feeding

Technical Specification

Executing Standard

Display

Keypad

Loadcell Interface

Speed Sensor Interface

Switch Signal Interface

Analog Signal Interface

Digital Communication Interface

Report Print

Weight Records per shift/day/month of a year can be queried and printed

Operating Specification

Operating Voltage: AC220V±15%, 50/60Hz

Max. Power Consumption: 5W.

Outline Size and Weight

Operating Temperature: -25℃ to +45℃.

Storage Temperature: -30℃ to +60℃.

Relative Humidity: Max. 85%RH.

Application Environment of Model Explosion-proof

Protection Level

Keypad Operation

If there is not any keypad operation in one minute and it’s not in the processes of ‘F2 System Calibration’ & ‘F6 Factory Adjustment’, the controller will return to ‘Main Display Interface’ automatically.

| Menu Operation | |

| Key Name | Description |

【MENU】 (【ESC】) | Enter Main Menu. Exit. |

| 【ENT】 | Enter/Save. |

| 【▲】 | Cursor shifts up or left. Display the previous interface or option. |

| 【▼】 | Cursor shifts down or right. Display the next interface or option. |

| 【0~9】 | Digit Input. |

| Quick Operation | |

| 【LOCK】 |

|

| 【F1】 | Return to the initial display interface. |

| 【SET】 | Flow Set Value Setting. |

| 【ADJ-】 | Control Current -1mA. |

| 【ADJ+】 | Control Current +1mA. |

| 【AUTO】 | ‘Manual/Auto’ Control Mode Selection. |

| 【EXT】 | ‘Internal/External’ Flow Set Mode Selection. |

| 【ZERO】 | Zero Calibration. |

| 【CAL】 | Dynamic Span Calibration. |

| 【CLS】 | Clear Screen: Clear display value of Totalized Weight. |

| 【REC】 | Query and print Weight Record. |

| 【PRINT】 | Print. |

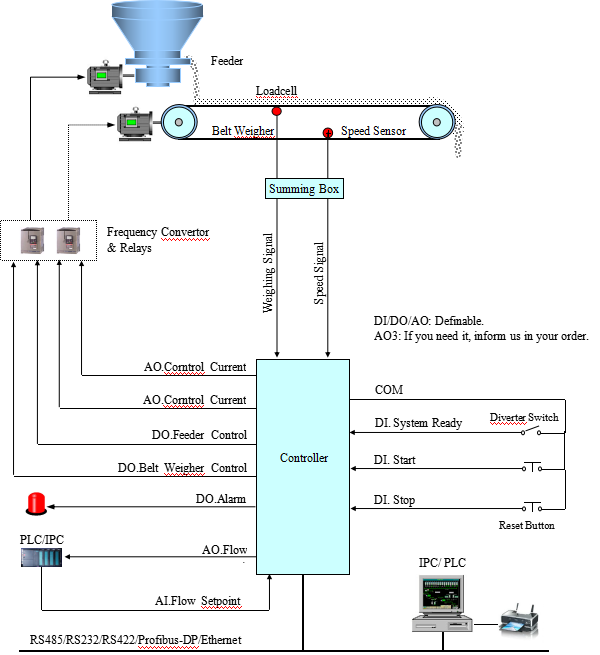

Ration Flow Auto-Feeding System: