Quanzhou Weforging Machinery Manufacturing Co., Ltd. |

|

Verified Suppliers

|

|

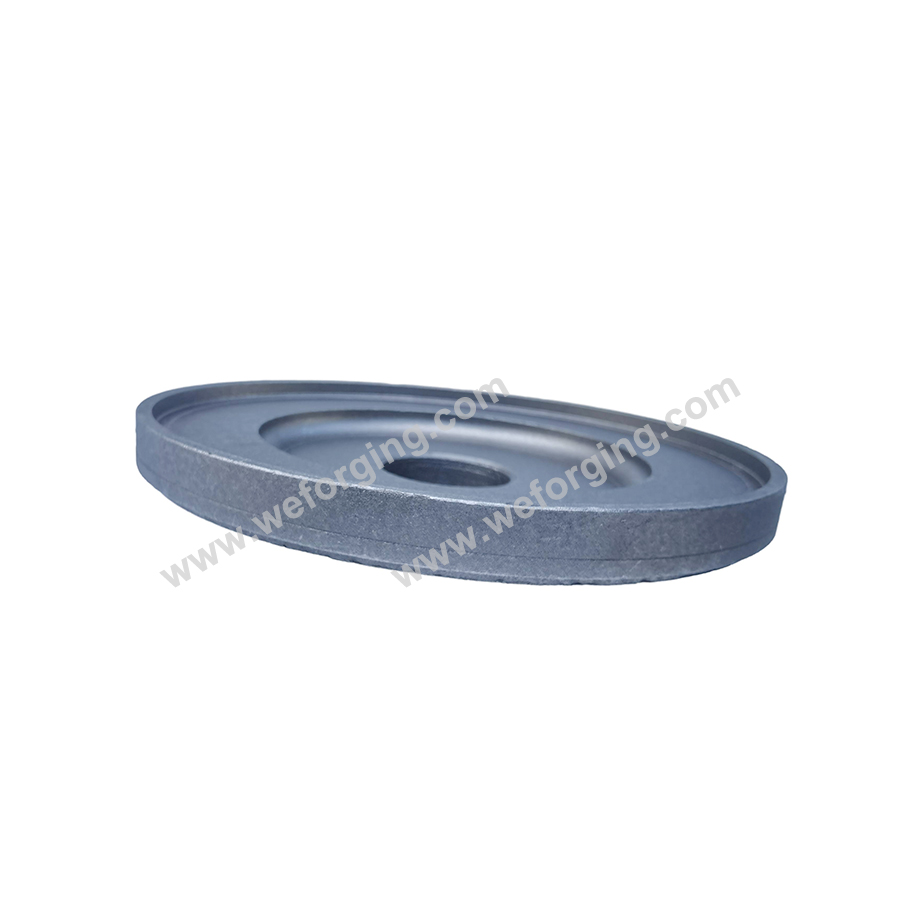

Custom Stainless Steel Rings And Aluminum Alloy Forging With SAM 4340 4140 316L 304L 8620H 42CrMo

Alloy Steel Forging is a process of rolling and forging steel shafts and components, made from alloy steel, which provides superior corrosion resistance, high ductility and a weight range from 0.5kg to 200kg. This process allows for customized sizes and shapes, making it a great option for a wide range of applications. The forged steel shafts and components are highly resistant to corrosion and abrasion, and can be customized to meet specific requirements. The forging process helps to increase the strength and durability of the alloy steel, making it a popular choice for industries such as automotive, aerospace, and marine.

Alloy Steel Forging has many advantages over traditional forging processes, such as lower cost, higher precision, and increased efficiency. The forged steel shafts and components produced are of superior quality and are more resistant to wear and tear. This makes them ideal for industrial and construction applications. The process is also very efficient and can be completed in a short amount of time, making it a great choice for large scale projects. The process also helps to create highly complex shapes and components, which can be customized to meet specific requirements.

Alloy Steel Forging is a great choice for any application that requires durability, strength, and corrosion resistance. The process is cost-effective, efficient, and provides superior quality components. It is ideal for a variety of industrial, construction, and automotive applications.

| Parameter | Value |

|---|---|

| Material | Alloy Steel, Stainless Steel (316L), Aluminum Alloy, Copper, Titanium |

| Heat Treatment | Normalization, Tempering, Annealing |

| Corrosion Resistance | High |

| Process | Forging |

| Impact Resistance | High |

| Strength | High |

| Ductility | High |

| Roughness | Ra1.6 |

| Shape | Customized |

| Size | Customized |

ODM's Alloy Steel Forging is an ideal choice for a variety of industries, from automotive to aerospace and shipbuilding. Its excellent ductility and strength makes it ideal for applications that require precise and complicated shapes. The forged steel shafts also boast a high tolerance of ±1.5-2mm for superior performance. The alloy steel forging is certified to ISO 9001:2005 standards, ensuring quality and reliability. ODM's alloy steel forging is also available in sizes customized to fit your specific requirements. The material used for ODM's alloy steel forging is a combination of alloy steel, stainless steel, aluminum alloy, copper, and titanium. The weights range from 0.5-200kg, making it suitable for a wide variety of applications.

ODM provides the highest quality alloy steel forging for all of your forging needs. It comes with a minimum order quantity of 300 and prices that are negotiable. The packaging for ODM's alloy steel forging is also of the highest standard, with plywood pallets, steel frames, and cardboard boxes ensuring safe delivery. Delivery times vary from 25-60 days depending on the size and quantity of the order. Payment terms are TT and ODM has the ability to supply between 3000-5000 tons per month.

Forged steel shafts are used in a wide range of industries, including automotive, aerospace, and shipbuilding. The high strength and ductility of ODM's alloy steel forging make it a perfect choice for applications that require precise and complicated shapes. The high tolerance of ±1.5-2mm ensures superior performance for even the most difficult of tasks.

If you are looking for the highest quality alloy steel forging, then ODM is the perfect choice. With ISO 9001:2005 certification, you can be certain that you are getting the best quality product possible. The customizable sizes and negotiable prices make it easy to get the right product for your needs. So, when you need an expertly crafted alloy steel forging for your forging needs, look no further than ODM.

ODM provides custom alloy steel forging services for customers worldwide. Our forged steel products include 316L stainless steel, alloy steel forging, and other metal products. All products are manufactured to meet the highest quality standards, certified by ISO 9001:2005.

We offer minimum orders as small as 300 pieces, with competitive pricing and fast delivery time of 25-60 days. Payment terms are negotiable, and we can supply 3000-5000 tons of products per month. Our alloy steel forging process ensures high corrosion resistance, ductility and hardness (HRC50-60). We can also work with other materials such as stainless steel, aluminum alloy, copper, titanium and more.

Alloy steel forging is a manufacturing process that involves the shaping of metal using localized compressive forces. The forging process is typically used to produce components that require high strength and toughness. We provide technical support and service for alloy steel forging to ensure your parts are manufactured to the highest quality standards.

We provide technical support for alloy steel forging during the design and development stage. Our experienced staff can assist with product design and specification selection to ensure your parts meet all your requirements. We also provide guidance on how to maximize the benefits of alloy steel forging while minimizing costs.

Our staff is highly experienced in the selection and inspection of forging materials to ensure your parts are manufactured with the highest quality. We use the latest testing equipment to analyze material properties and verify dimensional accuracy. We also have the capability to inspect finished parts to ensure they meet specified requirements.

We provide timely delivery of alloy steel forged parts. Our experienced staff can provide project management and support to ensure all parts are delivered on time and to the highest quality standards. We also have the capability to arrange for drop shipping and expedited shipping if required for urgent orders.

Alloy Steel Forging Packaging and Shipping

Alloy Steel Forging is packaged and shipped in accordance with the customer's requirements. For large-scale orders, the product is typically packaged in wooden crates or metal containers for safety and security during shipment. For smaller orders, the product is usually packaged in cardboard boxes or bubble wrap. The product is then shipped via truck, train, or air depending on the customer's needs.

Q1: What is the brand name?

A1: The brand name is ODM.

Q2: Where is the place of origin?

A2: The place of origin is Quanzhou China.

Q3: What is the certification?

A3: The certification is ISO 9001:2005.

Q4: What is the minimum order quantity?

A4: The minimum order quantity is 300.

Q5: What is the packaging details?

A5: The packaging details are Plywood pallets, Steel frames,

Cardboard boxes.