Quanzhou Weforging Machinery Manufacturing Co., Ltd. |

|

Verified Suppliers

|

|

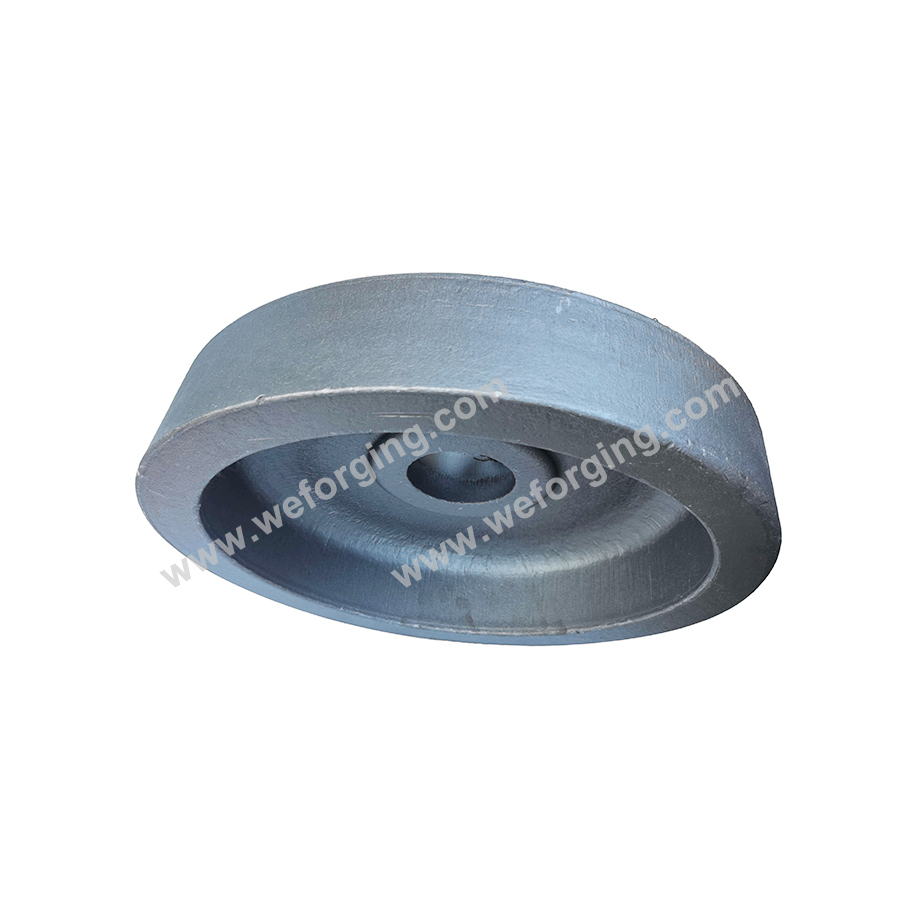

Gear Shaping Rolled Ring Forging Process With High-Strength Forged Gear Blanks Axle Shaft Forged Pipe Fittings

Rolled Ring Forging is a manufacturing process used to create rolled steel rings, rings that are customized in size and weight with materials such as steel, alloy steel, stainless steel, aluminum alloy, copper, and titanium. The process involves taking a solid steel ring and rolling it into a desired shape. The ring is then forged to create a seamless solid ring. This process is known as Rotten forging and it creates a strong, durable, and versatile product that is often used in industries such as construction and manufacturing. The rolled steel rings are also used in gears, sprockets, and other components. The custom size and weight can be tailored to meet individual specifications and requirements. After forging, the rolled steel rings are carefully packaged in cardboard boxes or wooden boxes for safe transport.

| Specification | Description |

|---|---|

| Payment Term | T/T |

| Weight | Customized |

| Material | Steel, Alloy Steel, Stainless Steel, Aluminum Alloy, Copper, Titanium |

| Packaging | Carton, Wooden Box |

| Process | Forging, CNC, Gear Shaping |

| Application | Machinery Parts Forged Parts |

| Size | Customized |

| Shape | Ring |

| Heat Treatment | Quenching And Tempering |

| Keywords | Forged Steel Rings, Circular Forge, Rolled Ring forging |

Rolled Ring forging is a kind of product mainly used in industrial machinery and equipment such as automotive, aerospace, mining, military and other industries. It is produced by ODM/OEM, a brand name from Quanzhou, China, with certification of ISO 9001:2005. The minimum order quantity is 200 and the price is negotiable. The packaging details can be tailored to customer requirements. Delivery time is 25-60 days and payment terms are TT. The supply ability is 3000-5000T per month. The size and weight of the product can be customized according to customer needs. Its shape is ring and the materials include steel, alloy steel, stainless steel, aluminum alloy, copper and titanium. Heat treatment is quenching and tempering, which can effectively improve the strength and hardness of the product. In conclusion, Rolled Ring forging is suitable for many fields and the product features are excellent. It is a reliable choice for customers.

We offer customized Forged Steel Rings, Rotten forging, Forged Ring, and Customized Forged Rings with the following attributes:

We are committed to providing technical and service support for our customers who use our Rolled Ring Forging products. Our technical and service support includes:

We are dedicated to providing the highest quality technical and service support for our customers. If you have any questions or need any assistance, please do not hesitate to contact us.

Rolled Ring forging is packaged and shipped in accordance with the customer’s specific requests. Depending on the size and complexity of the part, packaging may include wooden cradles, pallets, crates, steel bands, bubble wrap, shrink wrap, and other materials necessary for safe transport. The customer can also request additional protective measures such as rust-proofing and anti-corrosion treatments.

Shipping is usually done via truck, rail, or air depending on the size and urgency of the order. All packages are labeled with a tracking number, and customers can track their shipment in real time. We take extra care to ensure that all packages are handled with care and arrive in perfect condition.