Quanzhou Weforging Machinery Manufacturing Co., Ltd. |

|

Verified Suppliers

|

|

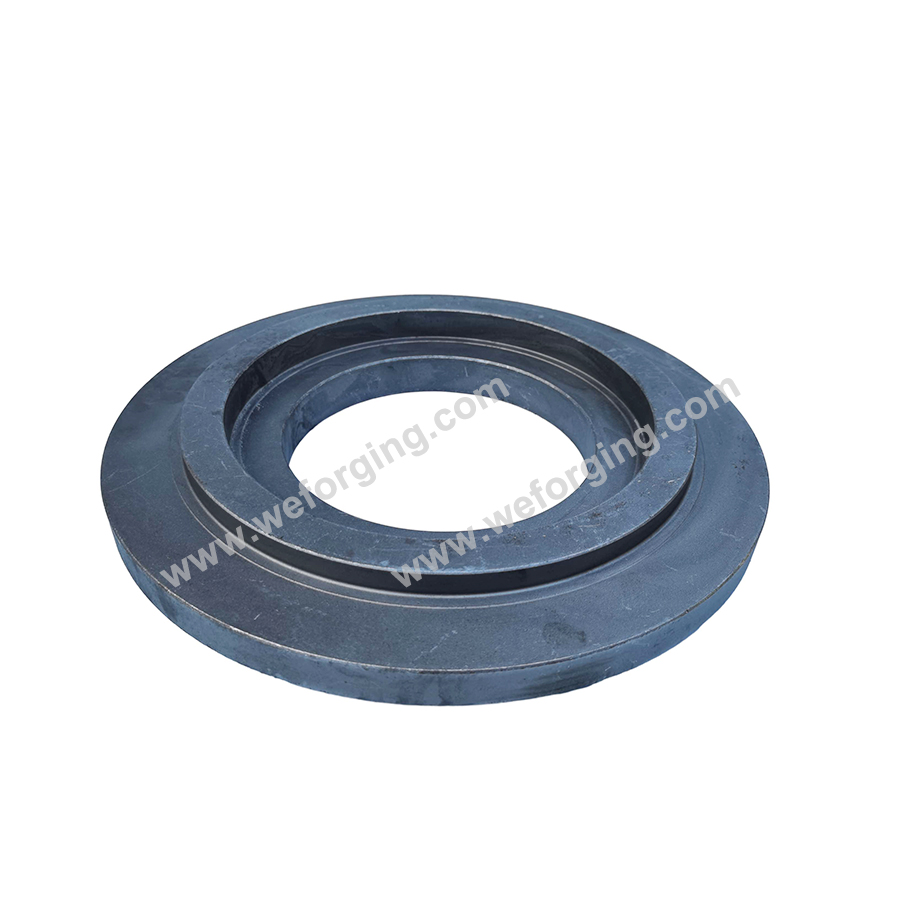

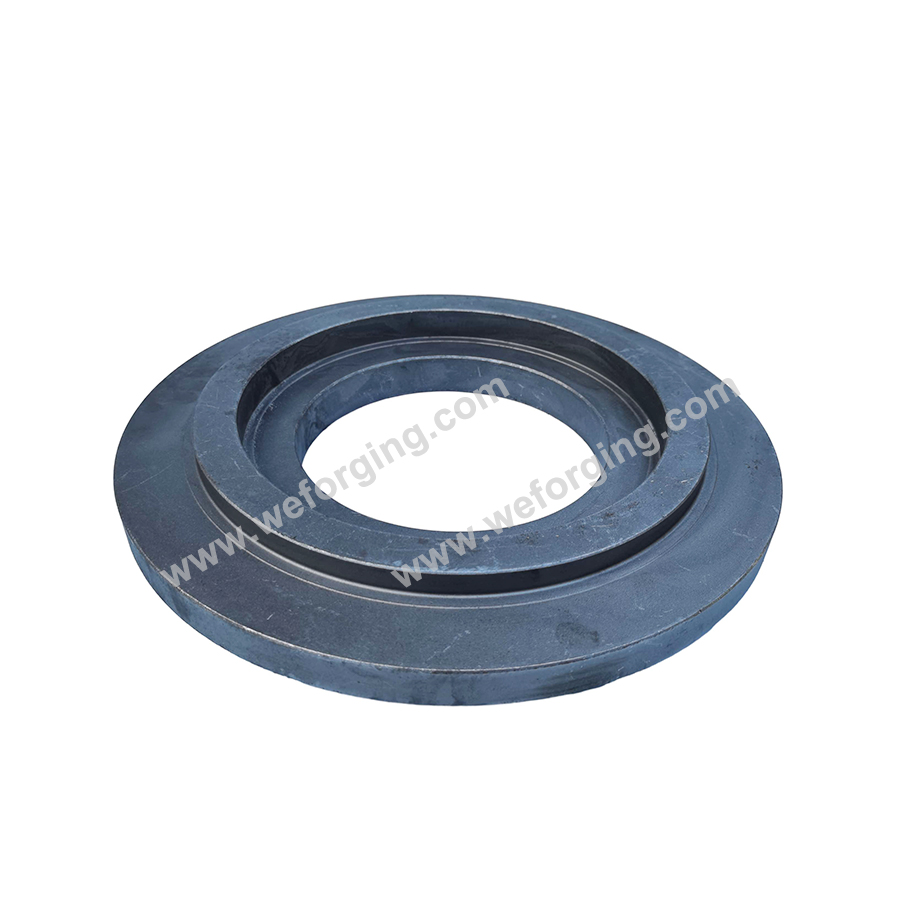

Versatile Rolled Steel Rings Customized To Your Industrial Needs Axle Shaft Forging And Forged Steel Ring Factory

Rolled Ring Forging is a kind of forging technique used to produce circular parts, such as circular forge, rolled steel rings and 4340 forged. It is widely used to make machinery parts, such as forged steel rings. The weight of the parts can be customized to meet the customers' requirements and the packaging can be either carton or wooden box. Payment term is usually T/T.

| Parameters | Value |

|---|---|

| Process | Forging, CNC, Gear Shaping |

| Packaging | Carton, Wooden Box |

| Shape | Ring |

| Size | Customized |

| Payment Term | T/T |

| Heat Treatment | Quenching And Tempering |

| Application | Machinery Parts Forged Parts |

| Weight | Customized |

| Material | Steel, Alloy Steel, Stainless Steel, Aluminum Alloy, Copper, Titanium |

| Forged Ring | Rolled Steel Rings, 4340 Forged Rings |

Rolled Ring forging is a metalworking process that is used to produce high-precision cylindrical parts. It is a specialized form of forging that is suitable for manufacturing parts with tight tolerances and complex geometries that are often found in aerospace, automotive, and medical industries. The process involves heating metal to a high temperature and then shaping it into a ring shape using a mechanical press. The metal is then rolled, or forged, to its desired shape and size. ODM/OEM offers Rolled Ring forging with Brand Name, Place of Origin from Quanzhou China, Certification of ISO 9001:2005, Minimum Order Quantity of 200, Price for Negotiation, Packaging Details based on Customer requirements, Delivery Time of 25-60 days, Payment Terms of TT, Supply Ability of 3000-5000 T per month, Size and Weight Customized, Material of Steel, Alloy Steel, Stainless Steel, Aluminum Alloy, Copper, Titanium, Process of Forging, CNC, Gear Shaping and Payment Term of T/T. It provides a great solution for Ring Metalwork, Forged Cylinder, Ring Metalwork, CNC Machining and Gear Shaping.

Rolled Ring forging is a specialized metal forming process that produces seamless rings of custom shapes and sizes for a variety of applications. We offer technical support and service to help our customers understand the process and ensure they are getting the most out of their rolled ring forging. Our team of experts are available to provide technical advice, troubleshooting, and design assistance to ensure your project is successful.

We offer product design and engineering services to help our customers create the most efficient and cost-effective rolled ring forging solutions. We can provide guidance on material selection, design optimization, and production methods. We also offer full-service production and machining capabilities to ensure the highest quality end product.

Our team of experienced metallurgists can provide detailed analysis and testing services to ensure your rolled ring forging meets all your specifications. We can also offer metallurgical and failure analysis to determine the cause of any defects or problems you may encounter.

For any questions or inquiries about our rolled ring forging services, please contact us today.

Packaging and Shipping for Rolled Ring forging:

Rolled Ring forgings are packaged and shipped in standard wooden crates, which are bolted and strapped for extra security. The crates are designed for easy handling and are marked for proper identification. Additionally, the packages are marked appropriately with the customer’s name and address, the weight and the number of the pieces contained in the package.

A1: Rolled Ring forging is a manufacturing process in which a metal is heated to a specific temperature and then rolled into a circular ring shape.

A2: The Brand Name of Rolled Ring forging is ODM/OEM.

A3: The Place of Origin of Rolled Ring forging is Quanzhou China.

A4: The Minimum Order Quantity for Rolled Ring forging is 200.

A5: The Payment Terms for Rolled Ring forging is TT.