Jinzhou City Shitan Machinery Equipment CO. LTD. |

|

Verified Suppliers

|

|

200 Meters Gold Mining Core Sampling Engineering Drilling Rig Machine

GK 200 Core Engineering Drilling Rig Information

It is a kind of hydraulic feed drilling rig, which has the characteristics of large power, large lifting force and large transmission torque. It is suitable for geological exploration, geological core drilling, small irrigation holes, blasting holes and small water wells of railway, water conservancy, bridge, dam foundation and other buildings. The drilling rig is light in weight, strong in decomposition, easy to move, and suitable for work in plain and mountainous areas.

GK 200 Core Engineering Drilling Rig Technical Data

| Drilling depth | 200m |

| Drilling Diameter | 91mm,110mm,130mm,150mm,300mm |

| Drilling rod diameter | 50mm |

| Drilling Angle | 90°-75° |

| Dimensions(L×W×H) | 1750×850×1300 (mm) |

| Weight | 880kg/set |

| Spindle Speed | 115, 230, 505, 790, 1010 r/min |

| Spindle stroke | 450mm |

| Spindle Dia. | Φ59mmx53mmx4350mm Kelly rod |

| Upward displacement speed of drilling vertical spindle | 0.05m/s |

| Downward displacement speed of drilling vertical spindle | 0.067m/s |

| Spindle pull-down max | 15KN |

| Spindle lifting capacity max | 25KN |

| Vertical maximum output torque | 1.5KN.m |

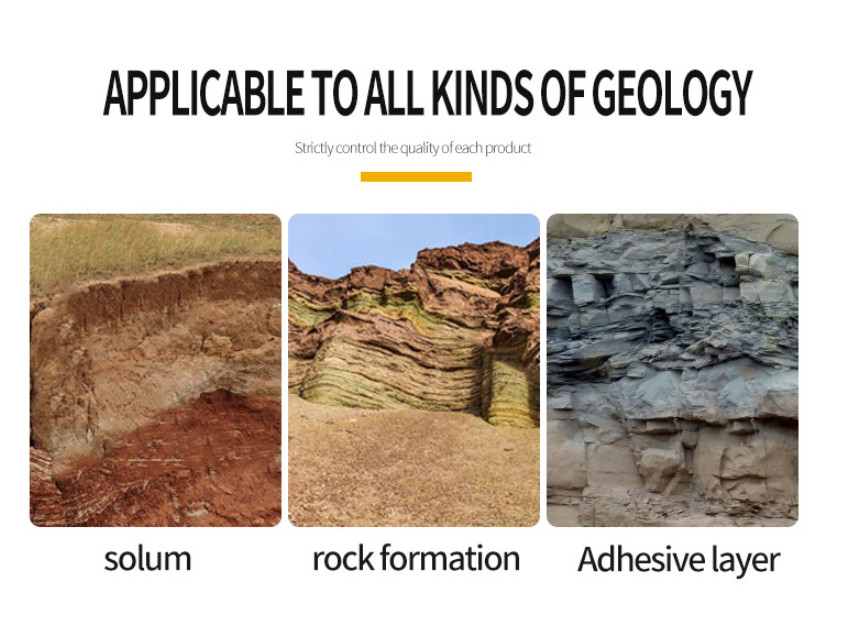

GK200 Engineering Drilling Rig Applications

1. Drillings for the general exploration and investigation of solid

mineral deposit, engineering geotectonic survey a

2.Diamond drill bit, alloy drill bit and steel roller drill bit and

so on are available for drilling according to different geological

structures.

3.When the final holes are respectively 75mm and 46mm in diameter,

the rated hole depths are separately 100m and 180m. The maximum

of depth may not exceed 110% of that drilled in each hole. The

maximum allowable hole diameter is 150 mm.

The main causes of drill pipe fracture

1, The bending moment of drill pipe is too large during reaming and pipeline pullback;

2, The causes of excessive bending moment are as follows: first, the actual curve of the guide hole deviates greatly from the theoretical curve; Second, the hole after reaming is irregular, which makes the pipe form an angle with the reamer and the drill pipe axis.

Other reasons:

1, In order to save investment, the directional drilling equipment used by the construction contractor (i.e. Party A) does not match the actual needs of the project construction. The tonnage of the directional drilling equipment is too small, the maintenance is not timely, and the failure rate is high, which makes the directional drilling force uneven. At the same time, the stop and go construction makes the hole forming quality poor, the hole irregular, the drilling tool is easy to lock, resulting in the fracture of the drill pipe;

2, The selection of reamer model is unreasonable. Failure to select the matching rule model according to the actual geological conditions, resulting in increased drilling torque, increased drill pipe wear and fracture;

3, When the rock reamer reams or cleans the hole, the drill pipe is not connected at the back, and the reamer swings greatly in the hole, which may cause the drill pipe and the main shaft of the reamer to break;