Suzhou Drimaker Machinery Technology Co., Ltd |

|

Verified Suppliers

|

Full Automatic Mango / Blueberry Juice Tea Filling machine Production Line

Juice bottling machine description:

The equipment is integrated with washing, filling and capping, it is suitable for the filling and production of all kinds of fruit juice drinks, energy drinks and tea drinks. with simple adjustment of some parts, the machine can also be used for pure water, mineral water filling production. Microgravity negative pressure filling technology, filling more quickly, stable, accurate, equipped with a perfect reflux system; It is equipped with CIP cleaning system, which can clean the liquid tank, pipeline and other liquid contact places. Using human - machine interface touch screen control, PLC computer control, inverter control technology.

Juice bottling machine parameters:

| Item | RCGF12-12-6 | RCGF18-18-6 | RCGF24-24-8 | RCGF32-32-10 | RCGF 40-40-13 |

Capacity bottles per hour | 2000-3000 | 4000-5000 | 7000-8000 | 9000-11000 | 12000-14000 |

Suitable bottle diameter | 50-90mm 200-2000ml | ||||

Filling temperature ℃ | 85-92℃ | ||||

Machine weight KG | 2500 | 3500 | 4500 | 5000 | 7000 |

Machine size L*W*H (mm) | 2400*1600 *2400 | 2400*1850 *2400 | 3100*2200 *2400 | 3600*2500 *2400 | 4000*2800 *2400 |

Juice Bottling machine features:

Generally, carbonic acid containing gas beverage, filling is more positioning or quantitative, the material from the bottle mouth always has a specified distance. And fruit juice, tea beverage, especially the production of original drink, the material filling, that is, until the bottle is full, so that the residual air in the bottle is minimal, to ensure that the drink itself is not easy to oxidize, so that the drink can maintain its quality for a long time.

Because hot filling should have the function of high temperature filling and full filling, it requires to be equipped with automatic circulation system, which is convenient for low-temperature material circulation heating and CIP circulation cleaning.

Juice bottling machine details:

Whole process:

The main process of the machine is that the bottles are transferred to the bottle stamping machine in the three-in-one filling machine through the air channel and the bottle picking star wheel.

The rinsed and drained bottle is imported into the filling machine from the punching machine, and the filling is made by gravity filling. After the filling valve is opened, the material is filled through the filling valve, and then is imported into the capping machine. The rotary cap keeps rotating and rotating on the rotary cap machine. Under the action of CAM, it can grasp the cap, cover the cap, screw the cap and take off the cap. The bottle after sealing is output by the conveying chain three-in-one filling machine.

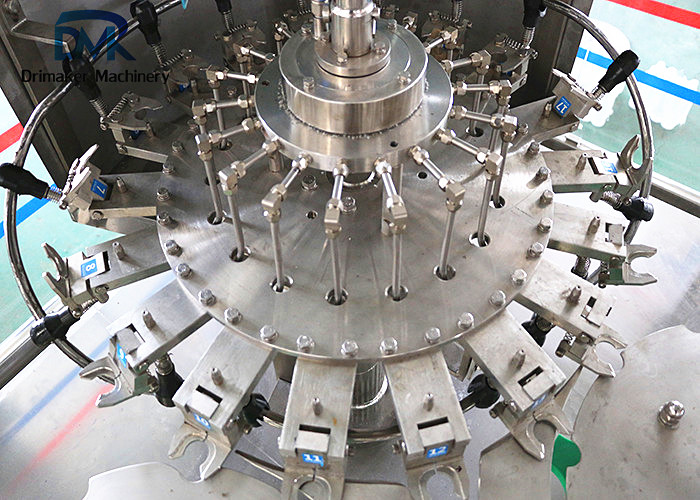

Bottle rinsing:

Bottles rinsing part clamps are made of SUS304, it wil grip the bottle neck to start the rinisng, so high quality stainless steel material makes

sure the rinsing area is clean and free from secondary contamination

Bottle filling:

Machine uses suspension type filling, different bottle type, bottle with different thickness can be used for it.

Liquid level in the tank can be automatic controleed, there is liquid leverl detection in the filling tank, and also level will be displayed on the

touch screen, if level is low, machine will control the valve of liquid inlet pipe open, and close it when liquid level is normal.

Screw capping:

High quality stainless steel capping head, there are several magnets inside, the magnetic twisting cover technology ensures the sealing is firm, and the torque is even and adjustable.

Equipped with missing cap detection system, if there are no enough caps in the capping system, machine will alert operator to feed caps in

advancem which ensures the continuous stability of production.

Thanks!

For more information please contact us!