Benenv Co., Ltd |

|

Verified Suppliers

|

|

Sludge Scraper Clarifier Flotation In Wastewater Treatment Dissolved Air Flotation Thickening

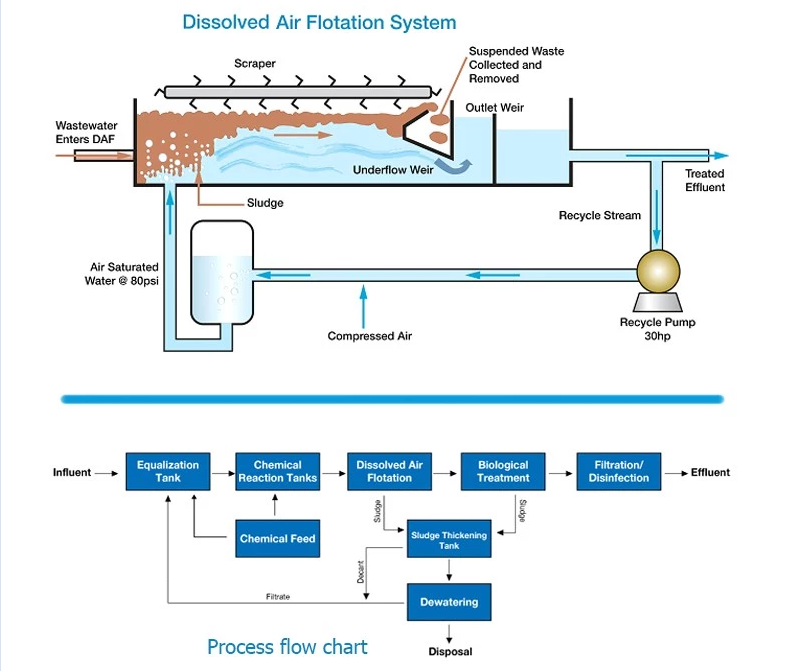

Brief Introduction of Dissolved Air Flotation

Oil Water Separator Wastewater Plant Treatment DAF Dissolved Air Flotation is an efficient flotation method for water clarification. The term refers to the method of producing flotation by dissolving air in the water under pressure and then releasing the pressure. When the pressure is released the solution becomes supersaturated with air as millions of small bubbles form. These bubbles attach to any particles in the water causing their density to become less than that of water. The particles then rapidly float to the surface for collection and removal, leaving the clarified water behind.

| Model | Capacity | Power(kw) | Dimension(m) | Pipe connection(DN) | ||||||

| (m3/h) | Recycle pump | Air compressor | Skimming system | L/L1 | W/W1 | H/H1 | (a) Water inlet | (b) water outlet | (c) sludge outlet | |

| BNDAF-002 | ~2 | 0.75 | 0.55 | 0.2 | 3.2/2.5 | 2.4/1.16 | 2.2/1.7 | 40 | 40 | 80 |

| BNDAF-003 | ~3 | 0.75 | 0.55 | 0.2 | 3.5/2.8 | 2.4/1.16 | 2.2/1.7 | 80 | 80 | 100 |

| BNDAF-005 | ~5 | 1.1 | 0.55 | 0.2 | 3.8/3.0 | 2.4/1.16 | 2.2/1.7 | 80 | 80 | 100 |

| BNDAF-010 | ~10 | 1.5 | 0.55 | 0.2 | 4.5/3.8 | 2.7/1.36 | 2.4/1.9 | 100 | 100 | 100 |

| BNDAF-015 | ~15 | 2.2 | 0.75 | 0.2 | 5.5/4.5 | 2.9/1.6 | 2.4/1.9 | 100 | 100 | 100 |

| BNDAF-020 | ~20 | 3 | 0.75 | 0.2 | 5.7/4.8 | 3.2/2.2 | 2.4/1.9 | 150 | 150 | 150 |

| BNDAF-030 | ~30 | 3 | 0.75 | 0.2 | 6.5/5.5 | 3.2/2.2 | 2.5/2.0 | 150 | 150 | 150 |

| BNDAF-040 | ~40 | 5.5 | 0.75 | 0.2 | 7.7/6.7 | 3.6/2.6 | 2.5/2.1 | 200 | 200 | 150 |

| BNDAF-050 | ~50 | 5.5 | 0.75 | 0.2 | 8.1/7.1 | 3.6/2.6 | 2.5/2.1 | 200 | 200 | 150 |

| BNDAF-060 | ~60 | 7.5 | 1.5 | 0.2 | 9.5/8.4 | 3.8/2.8 | 2.5/2.1 | 250 | 250 | 150 |

| BNDAF-070 | ~70 | 7.5 | 1.5 | 0.2 | 10.0/9.0 | 3.8/2.8 | 2.5/2.1 | 250 | 250 | 150 |

| BNDAF-080 | ~80 | 11 | 1.5 | 0.2 | 10.5/9.5 | 4.0/3.0 | 2.5/2.1 | 250 | 250 | 150 |

| BNDAF-100 | ~100 | 15 | 2.2 | 0.2 | 11.7/10.6 | 4.2/3.2 | 2.5/2.1 | 300 | 300 | 150 |

| BNDAF-120 | ~120 | 15 | 2.2 | 0.2 | 12.5/11.4 | 4.4/3.4 | 2.5/2.1 | 300 | 300 | 150 |

DAF equipment is liquid/solid or liquid/liquid separation process to remove tiny suspended solids that density close to the water, colloid ,oil and grease etc. Benenv DAF equipment is an innovation combined with traditional dissolved air flotation concept and modern technology.

Application Industry

The aim of dissolved air flotation is to separate the fine suspended solids in water, algae and micro-floc. And dissolved air flotation can be used in the following industries:

l Separate or recycle waste oil or grease in : oil exploration and refining, biodiesel, machining , food production and catering and so on.

l High concentration organic wastewater treatment: paper, printing and dyeing, textile, leather, pharmaceutical, fermentation wastewater and so on.

l Biochemical effluent liquid separation: the anaerobic effluent solid-liquid separation, aerobic (activated sludge process, contact oxidation, filter) biochemical water solid-liquid separation, the secondary settling tank Effluent treatment and so on.

l Farm and slaughter house wastewater treatment: cattle, pigs, chickens farm, slaughter house wastewater.

l Manufacturing waste: electroplating, painting, etc.

l Purification: river, landscape, recycle water and so on.

Packing and Delivery

1.The normal package is wooden box(Size: L*W*H). If export to European countries,the wooden box will be fumigated.If container is too tighter,we will use pe film for packing or pack it according to customers special request.

2.We also support 20',40' container delivery, use soft packaging to protect machine well. If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

Why Choose Us?

1. BENENV has more than 2 decades of experience in wastewater and sludge treatment.

2. We introduce Japanese technology and hire Japanese experts, thus our product is far more better than other Chinese manufacturers.

3. We only use the best parts from best supplier.

4. We have our own R&D center and complete manufacture system.

FAQ:

Q: Are You Trading Company Or Manufacture?

A: We Are Both Manufacture And Trading Company. We Have Over 30

Years' Professional Experience As a Waste Water Treatment Equipment

Manufacturer And Engineering Service Enterprise.

Q : What Are Your Main Products?

A:Keywords :Sludge Dewatering Machine Equipment, Screw Type Sludge

Dewatering Press Sludge Screw Press, Dewatering Sludge Machine

Screw Press ,Sewage Treatment Equipment ,Sludge Treatment

Plant,Screw Press Sludge Dewatering ,Dewatering Sludge,Dewatering

Machine For Sludge, Dewatering Sludge Machine Screw Press, Rotary

Drum Bar Screens, Equipment DAF, DAF Price ,Dissolved Air Flotation

System Price, Sludge Shaftless Screw Conveyor,Chemical Dosing

Device ,MBBR Price,MBBR Media,Disc Diffuser, Polymer Preparation

Chemical Dosing System,

Q: How Can I Find The Suitable Model?

A: Please Provide Flow Rate, Solids Content And Sludge Type, We Can

Assist You In Model Selection.

Q: Where Is Your Factory Located?

A: Yixing City, We are in the famous city of environmental

protection equipment ,professional for Sludge screw press

dewatering Machine ,Which Is Very Close To Shanghai With Only Less

Than 3 Hours' Driving. Welcome for your visiting.

Q: Do You Provide OEM Service?

A: Yes. We Can Do The Customized Design According To Your Different

Request for sludge Dewatering.

Q: How About The Production Capacity Of Your Company?

A: Our Factory Covers Area Over 22,000M2 And Produces Machines 2000

Sets Per Year.

Q: How Could We Trust You And Your Company? Is This Your First Time

Transaction?

A: A: Our Company Has More Than 30 Years Professional Experience.

We Cooperate Over 1000 Customers.In China And Overseas. We Export

Nearly 60 Countries All Over The World.And We Have More Than

60+Patents, CE,ISO 9001,SGS Certificates. And We Have Company In

Japan , Great Technology And Great Quality.

Q: Do You Offer After-Sales Service?

A: Video Technical Support, Online Support,Spare Parts,Field

Maintenance Repair Service

Q: How Long is Your Warranty?

A: 2 Years After The Arrival Of The Goods. During This Period, As

Long As It Is Not a Man-Made Damage, We Send The Damaged Parts Free

Of Charge.

Q: What About Your Produce Time?What Kind Of Transportation Do You

Offer?

A:Within 30 Days Against Down Payment. Air, Land & Sea .

Q: What Kind Of Payment Do You Accept?

A: T/T, L/C, Paypal, Cash, D/P, D/A, Western Union, Money Gram