Zhengzhou Hengyang Industrial Co., Ltd |

|

Verified Suppliers

|

|

Principle

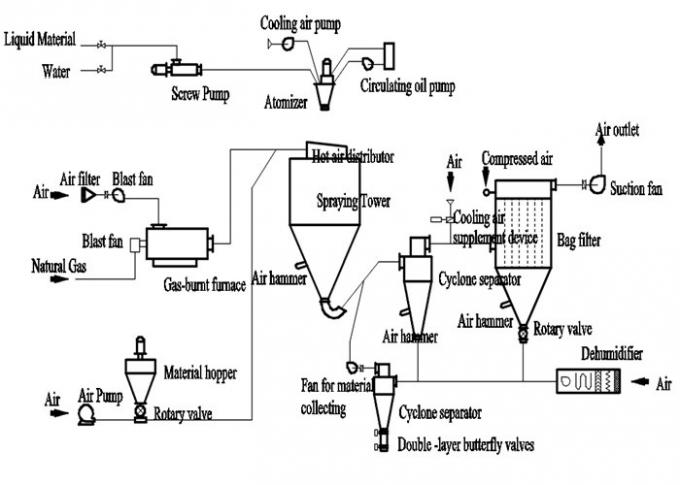

After been filtered and heated the air enters into the air

distrbutor on the top of the dryer.The hot air enters into the

drying room in the spiral form and uniformly. Passing through the

high-speed centrifugal sprayer on the top of the tower,the material

liquid will rotate and be sprayed into the extremely fine mist

liquid beads.Trough the very short time of contacting the heat

air,the materials can be dried into the final products.The final

products will be discharged continuously from the bottom of the

drying tower and from the cyclones. The waste gas will be

discharged from blower.

Features

1.compact structure, effective heat transfer area, small area

2.The mixing is uniform, high thermal efficiency, good drying

effect

3.the blade shaft can mesh with each other, with self-cleaning

effect, can prevent the material wall

4.Even of low energy consumption, small operating costs

5.small dust entrainment, less material loss

6.Indirect heating, no material pollution

7.The low rotation speed of liraglug impeller shaft, does not

damage the product shape and properties

8.Therefore the device to operate flexible, smooth and reliable

operation

Centrifugal spray atomizer Features

1.The drying speed is high when the material liquid is atomized,the

surface area of the material will increase greatly.In the hot-air

flow,95%-98% of water can be evaporated at a moment.The time of

completing the drying is only several seconds. This is especially

suitable for drying the heat sensitive materials.

2. Its final products own the good uniformity, flow ability &

solubility. And the final products are high in purity and good in

quality.

3. The production procedures are simple and the operation and

control are easy.The liquid with moisture contents of 40-60%(for

special materials,the contents might be up to 90%).can be dried

into the powder or particle products once a time. After the drying process, there is no need for smashing

and sorting,so as to reduce the operation procedures in the

production and to enhance the product purity.The product particle

diameters,looseness and water contents can be adjusted through

changing the operation condition within a certain range. It is very

convenient to carry out control and managment.

Technical parameters

| Model | HYG | |||||

| 5 | 25 | 50 | 100 | 150 | 200-2000 | |

| inlet temperatyre ℃ | 140-350 automatically controlled | |||||

| outlet temperatyre ℃ | 80-90 | |||||

| Max water evaporation capacity kg/h | 5 | 25 | 50 | 100 | 150 | 200-2000 |

| centrifugal spraying nozzle transmission mode | compressed air transmission | mechaical transmission | ||||

| rotation speed (r.p.m) | 25000 | 18000 | 18000 | 18000 | 15000 | 8000-15000 |

| spraying desc diameter (mm) | 50 | 100 | 120 | 140 | 150 | 180-340 |

| max electric heating power (kw) | 9 | 36 | 63 | 81 | 99 | settled by customer |

| overall dimensions | 1.8*0.93*2.2 | 3*2.7*4.26 | 3.7*3.2*5.1 | 4.6*4.2*6 | 5.5*4.5*7 | depends on tryer |

| dried powder collection | ≥95 | ≥95 | ≥95 | ≥95 | ≥95 | ≥95 |