Active Member

|

[China]

Address: No. 56, Chang'an Road, Baiyan Science and Technology Park, High-Tech Zone, Hefei City, Anhui Province, China, 230088

Contact name:Amy Zheng

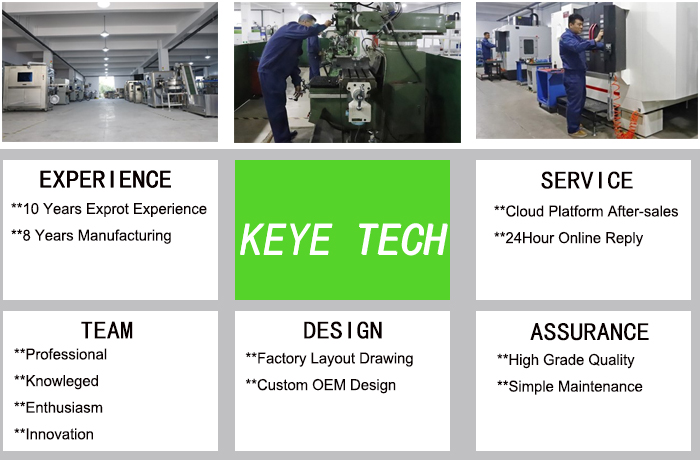

Anhui Keye Intelligent Technology Co., Ltd |

|

Instant Noodles Disposable Fork Defect Detection Equipment With Industrial Lens

Detection principle

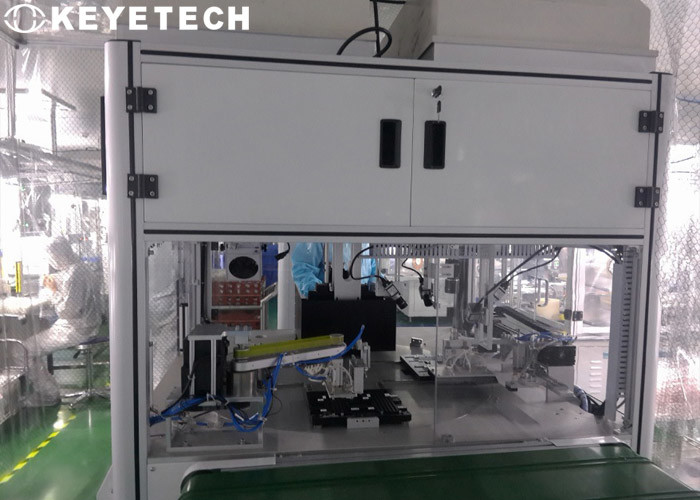

The appearance defect detection equipment of disposable fork is designed for the comprehensive detection of the defects of disposable fork in the production process. However, in the production process, due to some disadvantages of automatic production, the possible problems in the production process of forks cannot be found in time. Manual inspection will cost a lot of time, manpower and material resources, so many manufacturers need to equip professional equipment to carry out comprehensive inspection of product.

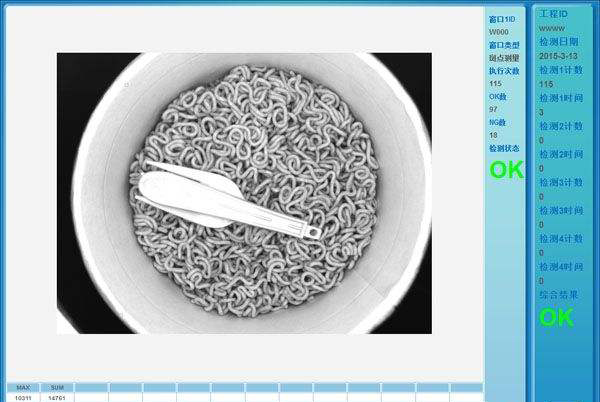

Disposable forks are stably transmitted to a specific detection station.Then transmitted the shooting high-pixel sample image to image processing software by industrial camera, detecting and determining a good product and defective product via AI manually intelligent algorithm, and controlling the corresponding pneumatic components to remove the defective product, and finally get the qualified product. The detecting machine rear end conveying platform can interface the automated packaging mechanism.

Equipment overview

-Online high speed detection, improve detection efficiency and accuracy, reduce human cost.

- High-pixel industrial camera accurate identification, the number of cameras is designed, accurate 0.1mm, speed 300 / min (can be customized according to the detection requirements).

- Compatible with multiple specifications, cost savings.

-Perform online detection and exclude for disabled fork defects:black spots, color difference, impurities, gaps, residues of material, overlaps, bubbles, air cavities, deformation, thickness, sizes, etc.

| Name | Disposable fork defect detection equipment | Model | Kvis-Sc02 |

| Software Algorithm | Deep Learning | Voltage | Ac220/50Hz |

| Voltage | 200w | Air Pressure | Mpa |

| Transfer Method | Lossless Delivery | Detection Status | Online Real-Time Detection |

| Detection Method | High-Speed Industrial Camera | Number Of Camera | 1 |

Our Advantages

|