Anhui Keye Information & Technology Co., Ltd. |

|

Fanta is one of the carbonated beverages that are often chosen by the public, and the good-looking packaging is the first step to attract consumers. The quality of packaging is often related to the image of a packaging company or a beverage company. In the current production environment with manual machines, high-efficiency production speeds often produce some subtle defects such as black spots, stains, and foreign objects. , label, mark, etc. The manual detection of these defects is not only inefficient, but also costly, and the false detection rate is relatively high. Therefore, the packaging visual detection of Keye Tech can imitate the human eye, and it has irreplaceable advantages in addressing packaging defects and bottle defects that are visible to the naked eye. In the use of enterprise production. It can also greatly save costs, improve efficiency, and increase benefits.

1. Detection principle

The system transports Fanta packaging bottle samples to the predetermined station in a stable and orderly manner, and then transmits the captured sample image to the GPU processing system through the high-pixel industrial camera, compares with the standardized sample and distinguishes the defective product and the good product, and controls the corresponding pneumatic components to reject defective products and collect qualified products.

The software sets the comparison standard for the samples, operators can control the comparison precision and choose the precision standard that best suits themselves, thereby controlling the defect rate and greatly reduce costs.

2. Detection details

Our design plan uses 11 sets of high-pixel industrial cameras and high-performance stroboscopic light sources to carry out comprehensive detection for bottle mouth, bottle bottom and bottle body defects. The whole set of detection equipment includes mechanical parts, visual electronic hardware and detection systems. The software, the entrance and exit of the detection machine can be integrated with the conveyor line, the detection speed is 9600 pieces/hour, the equipment can realize 7*24 hours of operation, and the unqualified products can be automatically rejected.

| System operating parameters | |||

| Dimensions | 2.3×0.85×1.8(m) | Power and frequency | 220V 20A 50HZ |

| Total power | 3.5kw | Air pressure | 0.5~0.8MPa Purify and oil-free |

| Working temperature | -20℃ ~ 60℃ | Working humidity | Below 50% relative humidity |

3.The detection standards are as follows:

| Model | Camera number | Detection range | Detection content | Detection accuracy | Detection precision | Detection speed |

| KVIS-C -SC11 | 1set | Bottle mouth | Black spots, stains, overlap, burrs, lack of material, etc. | ≥0.5mm | Qualified product 99.5% | 160 pcs/min |

False detection is less than 0.5% | ||||||

| 1set | Bottom of the bottle | Black spots, stains,foreign material, etc. | ≥0.5mm | 99.5%Qualified product 99.5% | ||

False detection is less than 0.5% | ||||||

| 4 set | Upper area of the bottle | Black spots, stains,missing, etc. | ≥0.5mm | Qualified product 99.5% | ||

False detection is less than 0.5% | ||||||

| 4set | Lower area of the bottle | Black spots, stains, etc. | ≥0.5mm | Qualified product 99.5% | ||

| False detection is less than 0.5% | ||||||

| 1set | Outer bottom of the bottle | Black spots, stains | ≥0.5mm | Qualified product 99.5% | ||

| Hole | ≥1mm | Qualified product 99.5% |

The counting function can be performed after detecting the finished product, and the counting accuracy is 100%.

Detection equipment requires regular maintenance cleaning (camera cleaning, etc.) during use, the equipment itself does not produce sources of secondary contamination (such as debris, fine foam, etc.).

4. Detection software function:

-Open and close the system detection function

-Adjustment of detection index parameters and accuracy.

-Template sampling and storage, sample detection information save and recall.

-Camera image calibration function

-The system displays real-time production information (qualification rate, total production, speed, etc.), historical production information browsing, export and save functions.

-Permission management based on the login account (such as general operation users disable parameter adjustment permissions)

-Operation and adjustment of the mechanical part of the system

(Such as open the transmission device, the adjustment of the air valve blow time, and the adjustment of the alarm signal)

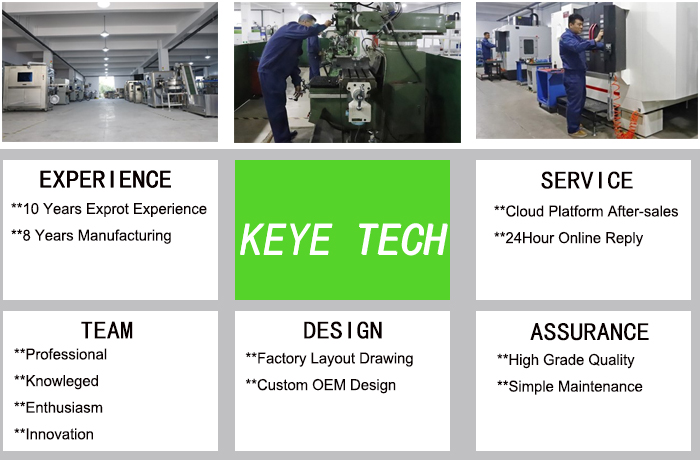

Our advantages