Anhui Keye Information & Technology Co., Ltd. |

|

Inspection Standard

| Model | Number of camera | Inspection scope | Inspection content | Detection precision | Capacity |

| KVIS-C-SC006 | 1 set | Top area | 0.2mm<Black spot | 99% | 150-200 Pc/min |

| 0.5mm<Rag | 99% | ||||

| 0.5mm<Oily dirty (with obviously color difference) | 99% | ||||

| 4 sets | Visible position of the side of the outer cover and the inner cover | 0.2mm<Black spot | 99% | ||

| 0.5mm<Oily dirty (with obviously color difference) | 99% | ||||

| 1 set | Cover bottom and inside of cover bottom | 0.2mm<Black spot | 99% | ||

| 0.5mm<Injection incomplete, flash | 99% | ||||

| 0.5mm<Oily dirty (with obviously color difference) | 99% |

About the inspection system

The maternal and infant industry is a relatively popular industry in recent years. With the current severe situation of environmental pollution, newborns are the most delicate. Therefore, the products used by infants are increasingly scrutinized by consumers in the market. Branded companies are also increasingly demanding manufacturers. However, during the production process of the nipple cover, due to the large production batch, the traditional manual inspection cannot meet the actual production requirements.

At the same time, due to the subjectivity of manual inspection, it

will affect the accuracy and false detection rate of the actual

product inspection to a certain extent. . Therefore, Keye Tech uses

its own industry advantages to formulate a complete set of testing

plans for the pacifier combination cover. Actually, the testing

plan can be adjusted according to the requirements of customers or

brands.

At the same time, due to the subjectivity of manual inspection, it

will affect the accuracy and false detection rate of the actual

product inspection to a certain extent. . Therefore, Keye Tech uses

its own industry advantages to formulate a complete set of testing

plans for the pacifier combination cover. Actually, the testing

plan can be adjusted according to the requirements of customers or

brands.

Test product sample description

This program is aimed at the detection of the pacifier combination cover, and the colors are transparent, red, and yellow. The product specifications are as follows:

Inspection Details

The inspection equipment includes mechanical parts, visual electronic hardware and inspection system software. Both parties need to predetermine the height of the conveyor line to facilitate the on-site equipment docking.

The counting function can be realized after the finished product is tested, and the counting accuracy rate is 100%.

The equipment needs to be regularly maintained and cleaned during use (such as conveyor belt cleaning, camera cleaning, etc.). The testing equipment itself will not cause secondary pollution sources (such as debris, fine foam, etc.) to the tested samples.

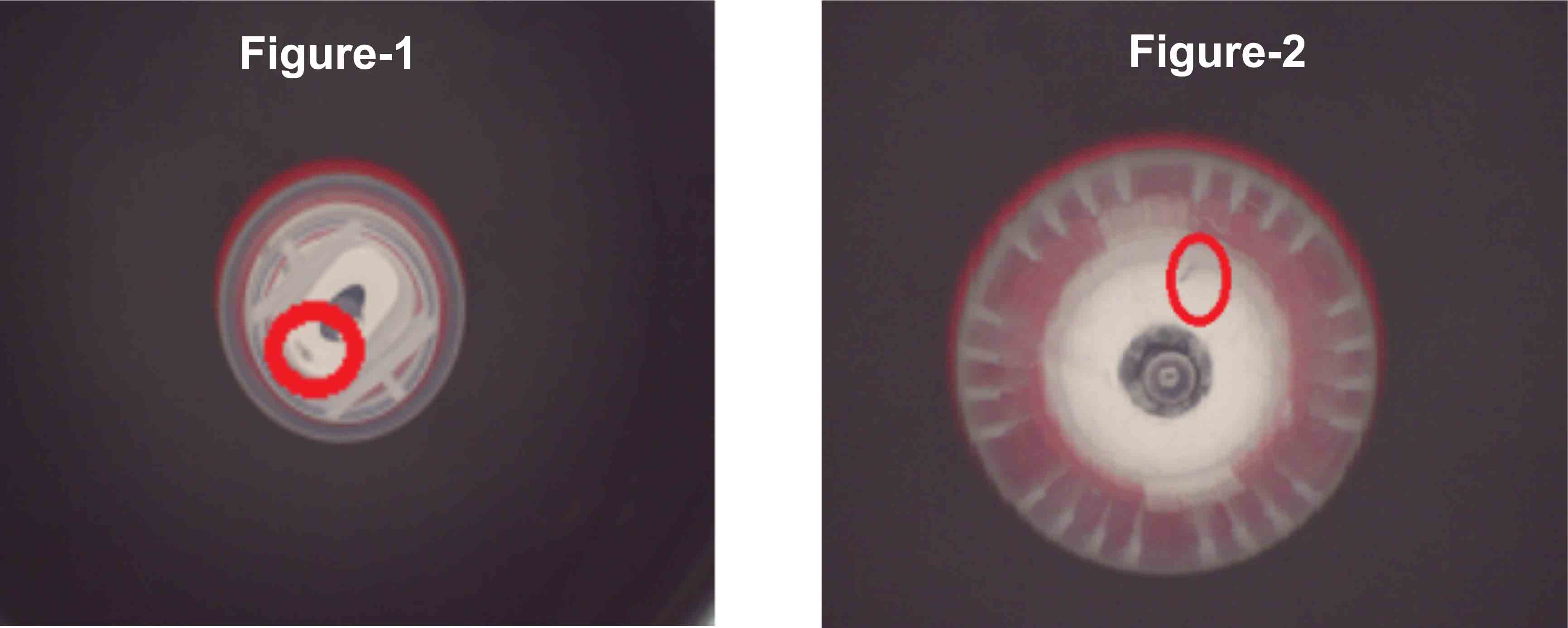

6, Picture reference

Figs. 1 and 2: Visible position of the side of the outer cover and the inner cover

Side position Edge of bottom lip and inside lip