Anhui Keye Information & Technology Co., Ltd. |

|

The aluminum cover is a part of the packaging for wine products, and also a part that reflects the brand characteristics and value meaning. The wine cover not only serves as a packaging, but also has various information such as trademarks, production batch numbers, and production dates. Concentrated. Many wine packaging brands will choose this type of wine lid. Therefore, people bear the brunt of the inspection item in the packaging inspection. However, due to the small size of the wine lid, the production is more mechanized. In the mass production process, Due to the influence of the production environment and production process, the wine cover may have black spots, burrs, stains, uneven thickness, shape variations and other problems. The manual inspection by workers is relatively slow and the accuracy rate is also impossible. Guarantee, therefore, in order to improve production efficiency, improve product quality, and increase their output value, it is an inevitable choice for many wine packaging manufacturers to choose high-tech visual inspection machines.

Test object: all kinds of alcohol aluminum bottle caps

Inspection Details

Inspection Standard

| Model | Number of camera | Inspection scope | Inspection content | Detection precision | Accuracy | Capacity |

KVIS- SC08 | 1 set(inner) | Inner side | Contamination | ≥0.5mm | 99.5% | 400pcs/mins |

| 1 set | Inner bottom | No Gasket | - | 99.9% | ||

Gasket dirty , not smooth | ≥0.3mm | 99.5% | ||||

| 1 set | Lip area | Transformation, not smooth, broken | ≥0.5mm | 99.5% | ||

| 1 set | Top area | Contamination | ≥0.3mm | 99.5% | ||

Bad printing | 99.9% | |||||

Scratches | ≥1*1mm | |||||

| 4 sets | Side area | Contamination | ≥0.3mm | 99.5% | ||

Bad printing | ≥0.5mm | 99.5% |

Functions

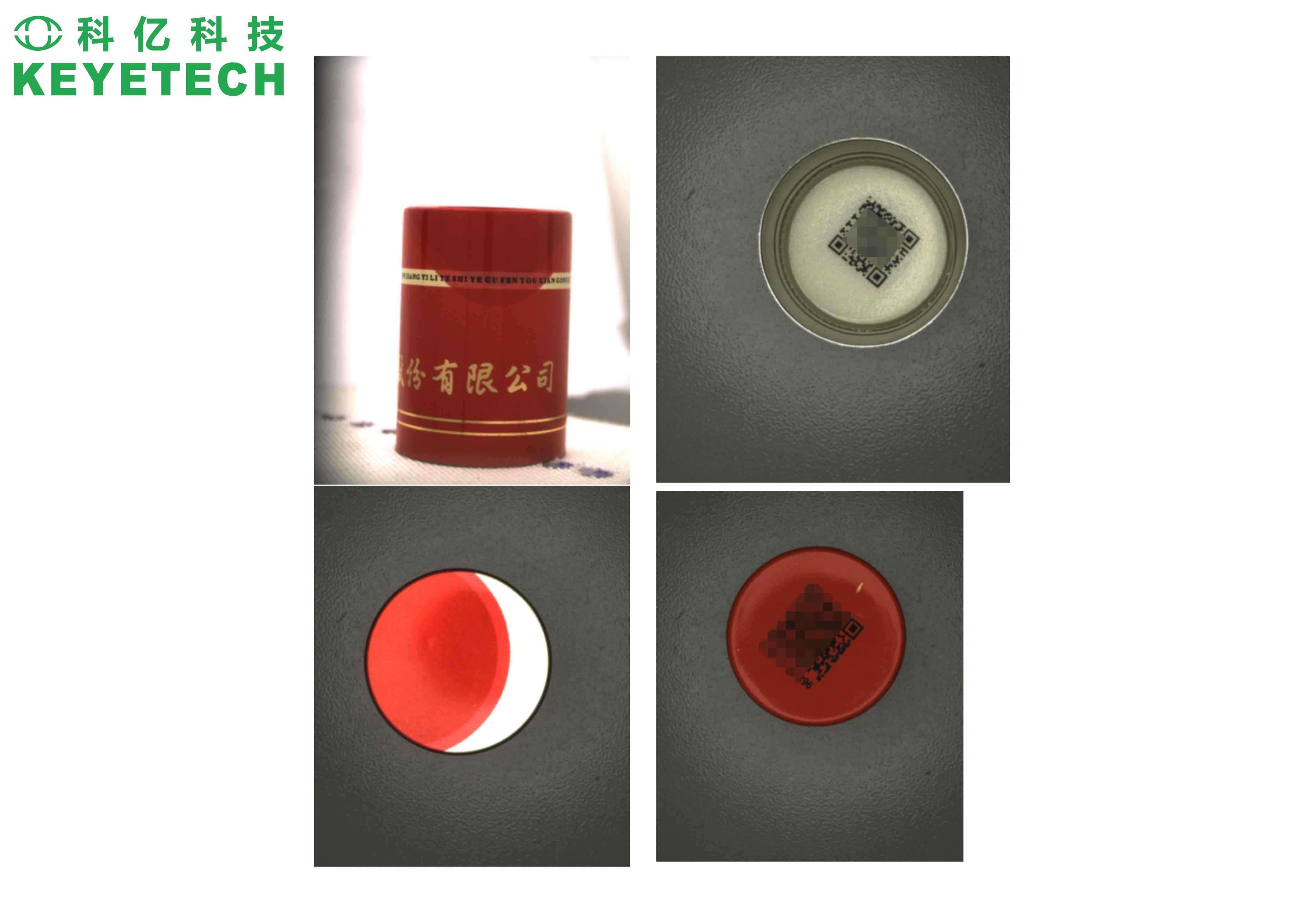

Image capture samples

The following patterns show some examples of defective sample patterns, including but not limited to the defects shown in the following images

Summary

Our design plan uses 8 sets of high-pixel industrial cameras and high-performance stroboscopic light sources to conduct a full range of defect inspections for the appearance of red wine bottle caps. The whole set of inspection equipment includes material handling equipment, mechanical transmission parts, visual electronic hardware and inspection systems The software, the whole equipment can be independently arranged on the customer site, the inspection speed is 400 pieces per minute, the equipment can realize 7*24 hours operation, and the unqualified products can be automatically rejected online.

The software will open the sample comparison standard, and the production personnel on the customer site can control the comparison accuracy and choose the accuracy standard most suitable for their own production conditions, thereby controlling the defect rate.