Changzhou Victory Technology Co., Ltd |

|

Verified Suppliers

|

|

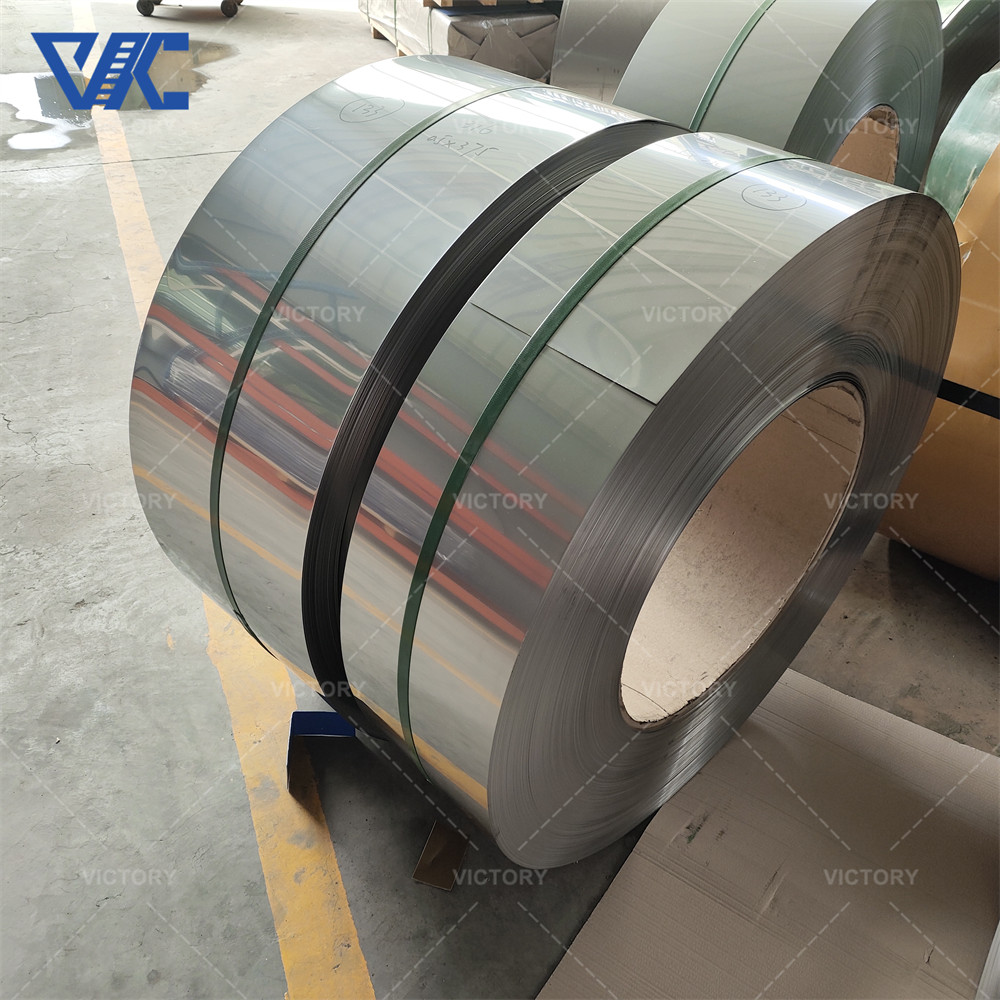

Vacuum Heat Treatment Cr20Ni80 Nickel Chromium Strip With Resistivity 1.09+/-0.05

Product Description:

Cr20Ni80 nickel chromium alloy strip is a highly favored

high-quality material in the field of vacuum heat treatment. Its

composition contains at least 77% nickel and a certain proportion

of chromium, which gives it excellent high-temperature stability.

Its melting point can reach as high as 1400-1450 ° C, and it can

still maintain the stability and performance of its structure under

extreme heating conditions.

This type of alloy strip has good electrical resistivity, about

1.1-1.2 μ Ω m, and is suitable for various high-temperature

electric heating processing processes. Meanwhile, its strength is

also very impressive, with a tensile strength of 637MPA and a

hardness of HV400-500. Not only that, it also has a elongation rate

of over 20%, making it more resilient in processing and application

processes. In terms of heat conduction, The Cr20Ni80 alloy strip

exhibits excellent performance with a thermal conductivity of 15-20

W/mK, which is crucial for uniformly heating the sample in a

high-temperature environment.

In addition, this alloy strip provides a choice of hardness or

softness state, and can be subjected to surface treatment as

needed, such as brightening and oxidation treatment. This makes it

very suitable for various applications such as vacuum furnaces,

heat treatment rooms, temperature control systems, etc.

Overall, Cr20Ni80 nickel chromium alloy strip has become one of the

preferred materials in the field of vacuum heat treatment due to

its excellent performance characteristics, providing reliable

guarantee and flexible selection for high-temperature processing.

Size dimension range:

Wire: 0.01-10mm

Ribbons: 0.05*0.2-2.0*6.0mm

Strip: 0.05*5.0-5.0*250mm

NiCr series: Cr10Ni90,Cr20Ni80, Cr30Ni70, Cr15Ni60, Cr20Ni35, Cr20Ni30

Technical Parameters:

| Performance material | Cr20Ni80 | |

| Composición | Ni | Rest |

| Cr | 20.0~23.0 | |

| Fe | ≤1.0 | |

| Temperatura máxima℃ | 1200 | |

| Punto de fusion ℃ | 1400 | |

| Densidad g/cm3 | 8.4 | |

| Resistividad μΩ·m,20℃ | 1.09±0.05 | |

| Alargamiento a la ruptura | ≥20 | |

| Calor especifico J/g.℃ | 0.44 | |

| Conductividad térmica KJ/m.h℃ | 60.3 | |

| Coeficiente de expansión de líneas a×10-6/(20~1000℃) | 18 | |

| Estructura micrográfica | Austenite | |

| Propiedades magnéticas | Nonmagnetic | |

| Form | Specification | |

| Wire | Diameter=0.025mm~8mm | |

| Flat wire | Width=0.40~6.0mm | Thick=0.03~0.50mm |

| Strip | width=8~250mm | Thick=0.05~3.0mm |

| Bar | Diameter=8~100mm | Long=50~1000 |

Characteristics:

Application:

Cr20Ni80 nickel chromium alloy strip plays an important role in vacuum heat treatment. Vacuum heat treatment is a heat treatment process carried out in anaerobic or low oxygen environments, usually used to improve the mechanical properties, corrosion resistance, and thermal stability of metal materials. In this process, The Cr20Ni80 alloy strip has the following key application aspects:

In summary, Cr20Ni80 nickel chromium alloy strip plays an important role in vacuum heat treatment, mainly used in heating element manufacturing, sample heating, oxidation protection, temperature control and monitoring, providing a reliable heating solution and temperature monitoring means for vacuum heat treatment.

FAQ :

Why is Cr20Ni80 nickel chromium alloy strip widely used in vacuum

heat treatment?

The Cr20Ni80 alloy strip has excellent high-temperature stability

and oxidation resistance, and can maintain stable chemical

properties in high-temperature vacuum environments. It is suitable

for heating and temperature monitoring during heat treatment.

What is its role in the manufacturing of vacuum furnace heating

elements?

Cr20Ni80 alloy strip is commonly used in the manufacturing of

heating elements for vacuum furnaces, to achieve high-temperature

treatment of materials, such as annealing, sintering, etc.

During sample heating, What are the characteristics of Cr20Ni80

alloy strip?

The Cr20Ni80 alloy strip can provide stable heating capacity,

making the temperature of the sample uniform and stable throughout

the heating process, thereby achieving the required phase

transformation or structural adjustment.

|  |