Changzhou Victory Technology Co., Ltd |

|

Verified Suppliers

|

|

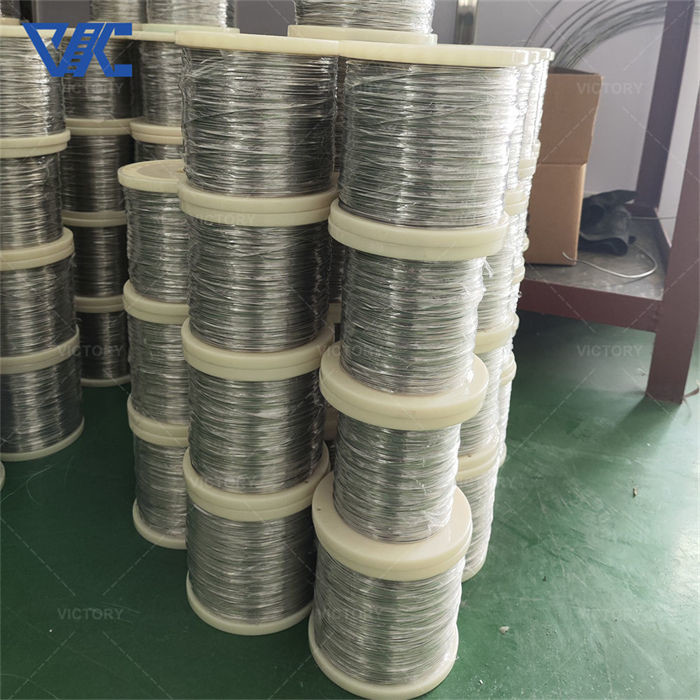

Electric Heating Element Cr10Ni90 Nichrome Alloy Wire NiCr Wire With High Resistivity

Product Description:

Cr10Ni90 Nichrome alloy wire is a high-performance material

composed of nickel and chromium, with a minimum nickel content of

89%. Its tensile strength reaches 637MPA, magnetic permeability

stabilizes at 0.78+/-0.05, and elongation exceeds 20%. It can be

used in hard or soft states and provides bright, oxidized, or

acidic surface treatment options. Widely used in fields such as

electric heaters, heating tubes, electric furnaces, and heat

exchangers, providing reliable support for various heating systems.

Cr10Ni90 nickel chromium alloy wire is renowned for its stable

resistance characteristics, excellent mechanical properties, and

diverse surface treatment options. Its high strength and high

elongation make it suitable for heating needs in various

high-pressure environments. Whether used as heating elements for

electric heaters, heating tubes, electric furnaces, or as materials

for heat exchangers, they can provide reliable support for heating

systems in different industries and meet diverse industrial needs.

Size dimension range:

Wire: 0.01-10mm

Ribbons: 0.05*0.2-2.0*6.0mm

Strip: 0.05*5.0-5.0*250mm

NiCr series: Cr10Ni90,Cr20Ni80, Cr30Ni70, Cr15Ni60, Cr20Ni35, Cr20Ni30

Technical Parameters:

| Performance material | Cr10Ni90 | |

| Composición | Ni | 90 |

| Cr | 10 | |

| Fe | - | |

| Temperatura máxima℃ | 1300 | |

| Punto de fusion ℃ | 1400 | |

| Densidad g/cm3 | 8.7 | |

| Resistividad μΩ·m,20℃ | 0.76±0.05 | |

| Alargamiento a la ruptura | ≥20 | |

| Calor especifico J/g.℃ | - | |

| Conductividad térmica KJ/m.h℃ | - | |

| Coeficiente de expansión de líneas a×10-6/(20~1000℃) | - | |

| Estructura micrográfica | - | |

| Propiedades magnéticas | - | |

| Form | Specification | |

| Wire | Diameter=0.025mm~8mm | |

| Flat wire | Width=0.40~6.0mm | Thick=0.03~0.50mm |

| Strip | width=8~250mm | Thick=0.05~3.0mm |

| Bar | Diameter=8~100mm | Long=50~1000 |

Cr10Ni90 characteristics:

Application:

NiCr alloy wire is widely used in various electric heating equipment, including heaters, electric furnaces, heating tubes, etc., due to its high electrical resistivity and excellent oxidation resistance. The following are the specific applications of Cr10Ni90 alloy wire in the field of electric heating elements:

Overall, Cr10Ni90 alloy wire has a wide range of applications in the field of electric heating components, and its excellent electrical and high-temperature resistance make it an important component of many electric heating equipment.

Shipping:

FAQ :

Q1: What are the advantages of Cr10Ni90 nickel chromium alloy wire

compared to other materials in the manufacturing of electric

heating components?

A1: Cr10Ni90 alloy wire has higher electrical resistivity and

better corrosion resistance compared to other materials, which

enables it to provide more stable and long-lasting thermal energy

output in electric heating elements, while also reducing

maintenance costs and replacement frequency.

Q2: What is the high-temperature stability of Cr10Ni90 alloy wire

and how high can it withstand?

A2: Cr10Ni90 alloy wire has excellent high-temperature stability,

which can work at temperatures above 1000 ℃ without losing

stability, making it an ideal choice for manufacturing

high-temperature electric heating elements.

Q3: What factors need to be considered when choosing Cr10Ni90

nickel chromium alloy wire as an electric heating element?

A3: When selecting Cr10Ni90 alloy wire, it is necessary to consider

its electrical resistivity, corrosion resistance, high temperature

resistance, and processability. In addition, factors such as the

specific application environment, required power, size

requirements, and safety standards of the electric heating element

should also be considered to ensure that the selected alloy wire

can meet all technical requirements and performance standards.

|  |