Changzhou Victory Technology Co., Ltd |

|

Verified Suppliers

|

|

Pure nickel belt is a belt-shaped material made of higher purity

nickel metal.

Pure nickel tape typically has excellent chemical stability, good thermal and electrical conductivity, and excellent corrosion resistance. This makes pure nickel tape widely used in many industrial fields.

Pure nickel tape is commonly used in the electronics, electrical and telecommunications industries to make resistors, inductors, cable shielding materials, thermistors, battery connectors, etc. Because pure nickel strip has high-temperature strength and corrosion resistance, it is also often used in applications in high-temperature environments, such as gas turbines, nuclear power plants, and chemical equipment.

In addition, pure nickel strips can also be used in the manufacturing of automotive parts, aerospace equipment, chemical equipment and medical equipment. Its high temperature performance and good mechanical properties make pure nickel belt play an important role in these fields.

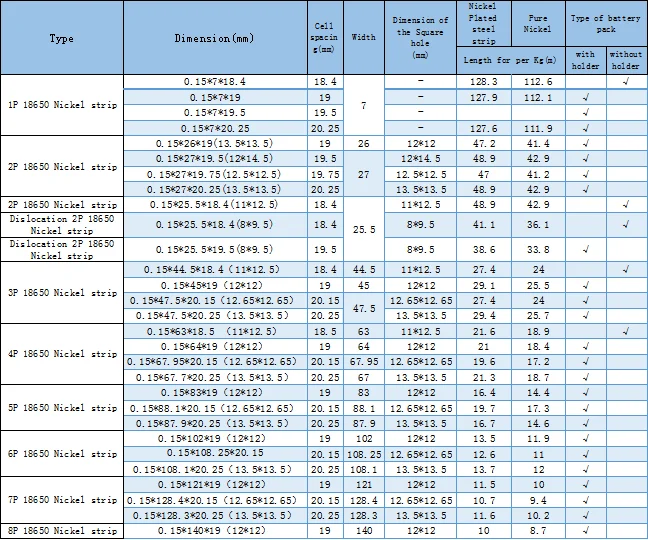

Pure nickel strip sizes and specifications can be customized to meet specific application needs. Common specifications include belt thickness, width and length, etc. In addition, pure nickel strip can also be processed and its properties adjusted through processes such as cold rolling, hot rolling and annealing.

1. Cold rolling: Cold rolling is a process in which pure nickel strip is cold deformed multiple times through a series of rollers, thereby changing its shape and size. Cold rolling can increase the hardness and strength of pure nickel strip and improve its surface quality and dimensional accuracy.

2. Hot rolling: Hot rolling is a process in which pure nickel strips are heated to a higher temperature and then plastically deformed through rollers. Hot rolling can significantly change the shape and size of pure nickel strip and improve its mechanical properties.

3. Annealing: Annealing is a process in which the cold-rolled or hot-rolled pure nickel strip is heated to a certain temperature and then slowly cooled. Annealing can eliminate the residual stress of pure nickel strip, improve its plasticity and toughness, and improve its processing performance.

4. Shearing: Shearing is the process of cutting pure nickel strips to a certain size through shearing machinery. Shear cuts long roll stock into the required length to meet the requirements of a specific application.

5. Bending: Bending is the process of bending pure nickel strip into the desired shape through mechanical or heat treatment. Bending can be used to manufacture parts and components of various shapes.

6. Welding: Welding is the process of joining two or more strips of pure nickel together by melting or pressure. Common welding methods include arc welding, laser welding, resistance welding, etc.

| Attribute | Value |

|---|---|

| Application | Chemical Industry, Battery Assembly |

| Conductor | Pure Nickel Connector |

| Melting Point(℃) | 1435-1446 ℃ |

| Ultimate Strength (≥ MPa) | 462 |

| Power Or Not | Not |

| Type | Pure Nickel Strip |

| Material Purity | >99.9% |

| Purity | 99.5%Min/ 99.9%Min(customized) |

| Elongation (≥ %) | 45 |

| Resistance (μΩ.m) | 1.5 |

| Keyword | Description |

|---|---|

| Nickel Strip Price | The cost of purchasing nickel strips for various applications. |

| Fused Nickel Strip | A type of nickel strip that has been fused or welded together for added strength and durability. |

| Pure Nickel Strip Price | The cost of purchasing pure nickel strips, which are made from 99.9% pure nickel. |

contact us

email:victory@dlx-alloy.com

Oem service:

Welcome customized size

We are experience factory for OEM&ODM service

|  |

What are the main components of pure nickel belt?

Pure nickel belt is mainly composed of pure nickel element.

In what fields are pure nickel belts widely used?

Pure nickel belts are widely used in aerospace, electronics,

chemical industry, energy, medical and other fields.

What is the typical delivery time for pure nickel strip?

The lead time for pure nickel strip depends on the size of the

order, customization requirements and the supplier's production

capabilities, and is usually between a few weeks to a few months.