Xinxiang AAREAL Machine Co.,Ltd |

|

Magnetic Powder Tumbler Screening Machine , High Accuracy Vibratory Separator

Introduction of Stainless Steel High Accuracy Tumbler Screening Machines for Magnetic Powder:

Stainless Steel High Accuracy Tumbler Screening Machines for Magnetic Powder is also known as the tumbler screen, tumbler screener, tumbling screen machine, tumbler sieve, swing screen etc.

It is used for the screening of bulk materials in all industries and is classified safely. Our Tumbler Screener is currently the most effective simulation principle of artificial screening motion (screening accuracy, efficiency, and screen life are 5-10 times that of conventional vibration screens), which meets all fine and ultrafine ranges of powders and particles Material, especially suitable for difficult materials. The imitation artificial design principle of the Tumler screening machine is a high-efficiency sieving machine specially designed to meet the needs of large-capacity and high-precision screening.

BALANCE IS IMPORTANT !! Pneumatic Lifting Device

Important Information About Stainless Steel High Accuracy Tumbler Screening Machines for Magnetic Powder:

| Motion | involute spiral motion |

| Screening Accuracy | upto 90%~99.9% |

| Diameter | 600mm, 800mm, 1000mm, 1200mm, 1500mm, 1600mm, 1800mm, 2000mm, 2300mm, 2600mm etc. |

| Mesh Cleaning Method | bouncing ball cleaning, ultrasonic de-blinding system, brush cleaning, air cleaning, ultrasonic air cleaning, air brush cleaning |

| Screen Structure | whole adhesive screen, or splicing segmented screen etc. |

| Layers of Screen | 1~5 layers of screen |

| Diameter | 600mm, 1000mm, 1200mm, 1400mm, 1500mm, 1600mm, 1800mm, 2000mm, 2100mm, 2300mm, 2600mm, 2900mm etc. |

| Advantages | soft rock screening will not destroy the particles original structure of the material and not easy to produce static electricity |

| Optional | quick clamps, pneumatic lifting devices etc. |

| Application | can be used for material that is flammable, explosive and easy to generate static |

| Motor Brand | Siemens, ABB, BEGEMA etc. |

| Surface Treatment | polishing, sandblast, paint spraying etc. |

Technical Parameters of Stainless Steel High Accuracy Tumbler Screening Machines for Magnetic Powder:

| Model | Screen Area (m²) | Layers of Screen | Motor Power (KW) |

| AM-600 | 0.28 | 1~5 | 0.25 |

| AM-1000 | 0.72 | 1~5 | 1.5 |

| AM-1200 | 1.10 | 1~5 | 1.5 |

| AM-1500 | 1.80 | 1~5 | 2.2 |

| AM-1800 | 2.30 | 1~5 | 4.0 |

| AM-2000 | 2.60 | 1~5 | 4.0 |

| AM-2300 | 3.90 | 1~5 | 4.0 |

| AM-2600 | 5.30 | 1~5 | 5.5 |

| AM-2900 | 6.40 | 1~5 | 5.5 |

Working Principle of Stainless Steel High Accuracy Tumbler Screening Machines for Magnetic Powder:

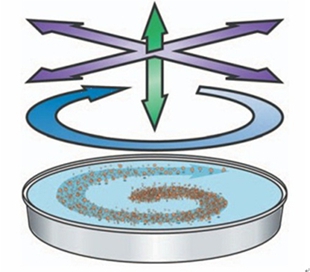

The tumbler screener machine is an artificial imitation of shaking low frequency vibration sieve. The adjustment of the machine in response to the product to be screened provides an exactly defined three dimensional eccentric motion pattern with radial and tangential inclination.

The basic rotary motion is similar to manual screening. Eccentricity is adjustable from 25 to 40mm, and low speed v-belt drive is adjustable from 120 to 360rpm. The residence time of each material can be adjusted by swinging the radial and corner cut of the sieve towards the driving axis.

So that build up a horizontal and throw 3D roll motion. Material from the center to the outer edge is evenly dispersed on the whole screen surface, thus propagating axially with spiral movement. This completes the whole screening process of fine particles.

The horizontal and vertical accelerations increase with the movement of the particles and the particles close to the size of the sieve hole separate successfully. The larger material is transported to the exit, where the flow is controlled by an adjustable guide which is another factor controlling the material residence time. This process is repeated between each screen.

Advantages of Stainless Steel High Accuracy Tumbler Screening Machines for Magnetic Powder:

1. Accurately separated six grades, screening efficiency as to 90-95%.

2. Using silicone rubber ball, ultrasonic and other high efficient

cleaning sieve device system, the sieve hole won't be blocked.

3. Enclosed to prevent dust, increased parts longevity, decrease

maintenance.

4. Noise is less than 75 dB.

5. Level and casting motion.

Application of Stainless Steel High Accuracy Tumbler Screening Machines for Magnetic Powder:

The tumbler sieve machine can be applied to the

processing of all the fine and ultra-fine powder and special

materials, particularly suitable for materials which are difficult

to classify.

Details are as follows:

Chemical, food and spices, plastics, mining, medicine, wood

and plywood, metallurgy, rubber, fodder, fertilizer, sugar, salt,

renewable industry.

Parameters