|

|

[China]

Trade Verify

Address: No. 107, North of Dingguo Village, Xinpu Road, Muye District, Xinxiang City, Henan Province, China

Contact name:Magie

Xinxiang AAREAL Machine Co.,Ltd |

|

Verified Suppliers

|

|

Multi Layer Linear Motion Vibrating Screens Wood Pellets Screening Equipment

Introduction of Multi-layer Linear Motion Vibrating Screens for Wood Pellets:

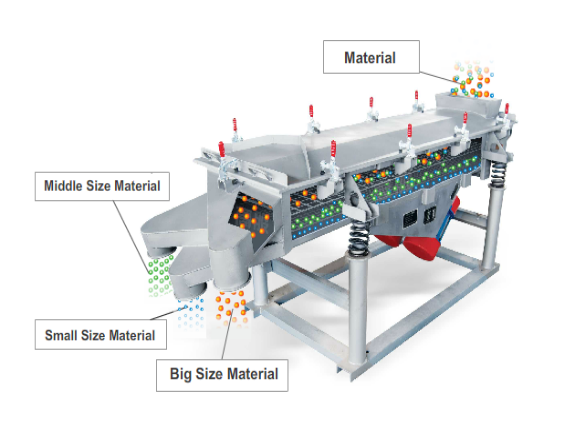

The Multi-layer Linear Motion Vibrating Screens for Wood Pellets adopts double vibrating motors as power source, with the specific working mode of these two motors make the materials be thrown up on the sieve and go forward in a straight line. It can be equipped with single or multi-decks to achieve different purposes like grading, removing impurity, removing dust, testing, washing selecting, dehydration and so on.

The rectangular separator can also be called linear vibrating screen, linear vibrating sieve, inclined vibrating screen, horizonal vibrating screen, rectangular vibrating screen, rectangular sifter, rectangular screener, linear screen etc.

Structure of Multi-layer Linear Motion Vibrating Screens for Wood Pellets:

The linear vibrating screen is composed of two vibration motors, a sieve box, a screen mesh, a vibration absorbing body and a vibration damping device.

1. Sieve box: welded by steel plate, with certain strength and rigidity, it is

the main component of screen machine.

2. Screen Mesh: the screen mesh is perforated plate. The overall stiffness is

good, solid and reliable.

3. Vibration motor: the vibration motor use and maintenance method to see the vibration motor operating instructions.

4. Motor pedestal: the motor pedestal of the down vibration type of sieve machine

(the motor is installed under the sieve box) can be moved. The

connecting screw must be tightened before using, Especially the new

screening machine must be repeatedly tightened three days before

trial, so as to avoid accidents caused by loosening.

5. Vibration damping spring: to prevent vibration from passing to the ground and support the

full weight of the screen box. When installing, the spring must be

perpendicular to the ground.

6. Bracket: the bracket is used to support the screen box. It must be mounted

perpendicular to the ground during installation. The bracket and

sieve body part shall be joined by the compression spring.

Working Principle of Multi-layer Linear Motion Vibrating Screens for Wood Pellets:

The AZ series linear vibration screener machine use vibration motor as vibration source, the material is rosed and moved in the straight at the same time. The material are entered into entrance equality, and then go through screen to create the materials with different sizes, which was discharged, from different gates. It is suitable for low consuming, high output, and simple structure, easily maintain all-closed structure, no powder dispersed.

Important Information About Multi-layer Linear Motion Vibrating Screens for Wood Pellets:

| Other Names | linear vibrating sieve, rectangular separator, inclined vibrating screen, horizonal vibrating screen, rectangular vibrating screen, rectangular sifter, rectangular screener, linear screen etc. |

| Shape | rectangular shape |

| Motion | linear motion |

| Structural Composition | screen box, screen, vibration motor, motor base, damping spring, support etc. |

| Vibrating Motor | two sets of horizontal vibrating motors, synchronous reverse rotation |

| Applicable Material | suitable for sieving 0.074mm~10mm non-sticky materials with moisture content less than 7% |

| Screen Surface | horizontal or inclined (0°~7°) |

| Layers of Screen | 1~6 layers of screen (The more layers can be customized according to the actual situation) |

| Screen Frame | wooden screen frame, carbon steel screen frame, stainless steel screen frame etc. |

| Mesh Deblinding System | bouncing balls, ultrasonic system etc. |

| Material | carbon steel, stainless steel 304/316L, titanium material etc. |

| Screen Size | screen width*length 500*2000mm, 500*2500mm, 1000*2000mm, 1000*2500mm, 1000*3000mm, 1000*4000mm, 1200*2500mm, 1200*3500mm, 1200*4000mm, 1500*3500mm etc. |

| Application | plastic particle, tea, chemical fertilizer, lysine, urea, organic fertilizer, limestone, fodder, feeding stuff, refractory material etc. |

Technical Parameters of Multi-layer Linear Motion Vibrating Screens for Wood Pellets:

| Model | Nominal Size (mm) | Particle Size (mm) | Leaning Angle of Screen (°) | Amplitude (mm) | Layer | Power (Kw) |

| AZ-520 | 500*2000 | 0.074~10 | 0~7° | 4~10 | 1~6 | 2*(0.4~0.75) |

| AZ-525 | 500*2500 | 2*(0.4~0.75) | ||||

| AZ-530 | 500*3000 | 2*(0.4~0.75) | ||||

| AZ-1020 | 1000*2000 | 2*(0.4~0.75) | ||||

| AZ-1025 | 1000*2500 | 2*(0.4~1.1) | ||||

| AZ-1030 | 1000*3000 | 2*(1.1~1.5) | ||||

| AZ-1040 | 1000*4000 | 2*(1.1~1.5) | ||||

| AZ-1225 | 1200*2500 | 2*(1.1~1.5) | ||||

| AZ-1235 | 1200*3500 | 2*(1.1~2.2) | ||||

| AZ-1250 | 1200*5000 | 2*(1.1~2.2) | ||||

| AZ-1535 | 1500*3500 | 2*(1.1~2.2) | ||||

| AZ-1560 | 1500*6000 | 2*(2.2~3.7) | ||||

| AZ-1845 | 1800*4500 | 0.074~15 | 2*(2.2~3.7) | |||

| AZ-2050 | 2000*5000 | 2*(2.2~3.7) | ||||

| AZ-2060 | 2000*6000 | 2*(2.2~3.7) |

Note: The data in the table are for reference only. Our company reserve the right to modify the above data.

Features of Multi-layer Linear Motion Vibrating Screens for Wood Pellets:

1. Simple structure, large screening capacity.

2. Sealed structure, no dust flying.

3. Bounce balls could prevent the mesh from be blocked through

jumping from up to down.

4. Robust construction for improved fatigue life.

5. Single layer or multi-layer are both available, can be installed

7 layers at most.

6. Manufactured in standard models or as per customer requirement.

Application of Multi-layer Linear Motion Vibrating Screens for Wood Pellets:

1. Ceramic industry: Alumina, quartz sand, slurry, glaze and

pigment etc.

2. Chemical industry: Resin, powder, paint, fine powder, soda,

citric acid etc.

3. Foodstuffs industry: Sugar, salt, alkali milk, powder, soybean

milk, yeast etc.

4. Pharmaceuticals industry: Chinese medicine powder, western

medicine powder etc.

5. Paper making industry: Black and white liquid paper, pulp, waste

water recycle etc.

6. Metallurgy: Metal powder, welding rod powder etc.

7. Pollutant treatment: Rubbish waste, oil animal, droppings etc.

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

WhatsApp/WeChat: 0086-15637361027

Website: https://www.aarealmachine.com