Xinxiang AAREAL Machine Co.,Ltd |

|

Triple Deck Vibrating Screen Vibro Sieve Separator For Chocolate Drink Powder

Overview of Multi-layer Circular Vibrating Screen Machine For Chocolate Drink Powder:

The multi-layer circular vibrating screen machine for chocolate drink powder is a revolutionary high performance vibrating screen for screening wet or dry materials. It is also known as the rotary vibrating screen, rotary vibrating sieve, round separator, vibro screen, vibrating sifter, round vibro sieve, gyro screen, gyro sieve, round sifter, round screener, round vibro sieve machine, round gyratory screen, rotary screen, rotatory vibrating screen, rotary vibrating sieve, circular vibratory screen, circular vibrating screen, circular vibrating sieve, gyro screen, gyro sifter, gyratory sifter, gyratory screen, gyratory sieving machine, vibro sifter, vibro separator, vibro grader, classic separator, vibratory separator, vibratory sifter, sanitary separators, filter sieve machine, industrial sifter etc.

The AY model vibrating screen classifier is one of precised powder sieve ,Low noise, high efficiency, need only 3-5 minutes to rapidly replace the screen, all closed structure. Used to filter particles, powder and mucilage.

The rotary vibrating screen machine is a kind of mature technology, general and tend to be standardized classic inertia screening equipment. It can meet the requirement of the most materials in grading granulated stuffs and screening out powder and liquid in different operation.

Application of Multi-layer Circular Vibrating Screen Machine For Chocolate Drink Powder:

1. Food industry: flour, milk powder, starch, soybean, fish meal,

rice flour, quinoa, vitamin, spices, dextrin, drinks, juice, sugar,

soy sauce, pineapple juice, yeast, the mother liquor etc.

2. Chemical industry: paint, tree cosmetics, PVC tree of cosmetics,

citric acid, PE powder, washing powder etc.

3. Ceramic abrasive metallurgy industry: bentonite,

attapulgite clay, aluminum silver pulp, mud, kaolin, quartz sand,

alumina, artificial black aluminum, graphite, silicon carbide,

spray soil grain, emery, iron powder, titanium dioxide,

electrolytic copper powder etc.

4. Pharmaceutical industry: pharmaceutical intermediates, medical auxiliary materials, this solution, west powder, and west solution etc.

Important Information You May Concern About Multi-layer Circular Vibrating Screen Machine For Chocolate Drink Powder:

| Model | AY |

| Shape | round or circular |

| Layers of Screen | 1~5 screen decks (with 2~6 discharge ports) |

| Mesh Size | above 325 mesh |

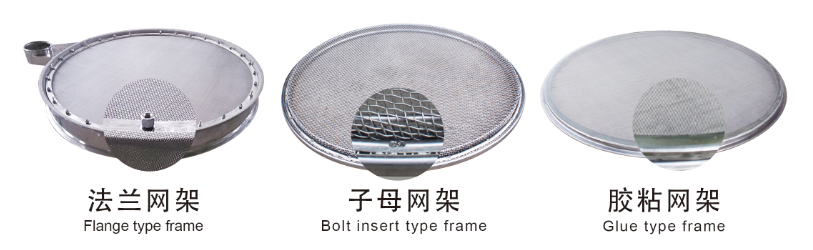

| Screen Frame | L type, adhesive type, ultrasonic type (transducer internal and external) etc. |

| Mesh Cleaning Method | bouncing balls, ultrasonic system, rotary brush system etc. |

| Diameter | 400mm, 600mm, 800mm, 1000mm, 1200mm, 1500mm, 1800mm, 2000mm |

| Material | carbon steel, stainless steel 304, 316L etc. |

| Function | grading, solid-separation, remove the impurity etc. |

| Movement | three dimensional vibration motion |

| Damping Spring | galvanized steel spring etc. |

| Motor | verticle vibrating motor |

| Motor Brand | China Made, OLI-WOLONG etc. |

| Optional | quick release clamp, magnetic guard, discharge gate, glass viewing port etc. |

1. it is suitable for screening all of dry material (from 0.074mm

to 20mm).

2. the dimension is ranged from diameter 400mm, 500mm, 600mm,

800mm, 900mm, 1000mm, 1200mm, 1500mm, 1800mm, 2000mm.

3. it supports at most 5 layers. But 3 layers is highly

recommended.

4. the material can be full stainless steel 304 or 316 or contact

part SUS304 or carbon steel Q235A.

5. the voltage is supported to be customized. 220/240/380/415/450V

are all available. 50HZ or 60HZ.

6. with large capacity, small volume, high screening efficiency,

easily changed screen and good safe performance.

7. it is widely used for screening, grading and filtering,

separating and classifying and sieving of powders, pellets,

granule.

8. it can be used in food, chemical, construction, paper-making,

metallurgy and mining, abrasive and ceramic industry etc.

9. it is composed of vibration motor, basement support, screen

frame, inlet and outlets, dust-proof cover etc.

Working Principle of Multi-layer Circular Vibrating Screen Machine For Chocolate Drink Powder:

The multi-deck rotary vibating screen separator adopts the latest vertical vibrating motor, which produces a horizontal, vertical and oblique vibration of three dimensional, and then directly passes the vibration to screen surface. Changing the angle of the upper and lower eccentric block of the motor, it produces different exciting force, and the direction in which the material is running is changed.

Its vertical motor, which is installed with eccentric hammers on the top and bottom, regarded as a vibratory source. The eccentric hammers change the track of rotation in to horizontal, vertical and inclined movement, and then pass the movement to the sieving surface. Adjusting the phase angle between the top and bottom eccentric weight can change trajectories of the materials on the sieve.

The general characteristics of the vibrator adjustment are described below:

Structure Diagram of Multi-layer Circular Vibrating Screen Machine For Chocolate Drink Powder:

Screen Frame Or Screen Holder For Optional:

Features of Multi-layer Circular Vibrating Screen Machine For Chocolate Drink Powder:

1. High efficiency, refined design,duration,any powers and mucilage

are suitable for using.

2. Easily replace the screen, simple operation and convenience

washing.

3. Never jam the mesh with no power flying and filter size of the

power between 500 mesh or 0.028mm.

4. Discharge the impurity and coarse materials automobile and

operates continuously.

5. Small volume, move easily.

6. The highest layers of the screen are 5 layers. But 3 layers are

suggested.

Optional Designs for Multi-layer Circular Vibrating Screen Machine

For Chocolate Drink Powder:

1. Discharge Gate: it is used to control production flow and speed.

This enables a better flow and provides consistent discharge

characteristics from even surfaces. However, the discharge rate

might differ from the ratio and diameter of the discharge pipe.

2. Quick Release Clamp: it is used for releasing camps rings

without the need to use tools. While the other side of the clamp is

used for tightening. It is mostly used for cleaning and dissembling

purposes.

3. Spring Dust Cover: it is used to provide additional protection

against dust and other particles by the strength of the springs,

which is determined by the rollers which are also spring-loaded.

4. Customised Dust Cover: it is used to reduce any leaks from the

machine. It also helps reduce airborne dust from flowing on the

steam or conveyer belt. This device is made custom to fit your

production line.

5. Magnetic Guard: it is used for preventing any contamination and

also to ensure that manufacturing is done safely and free from any

irregularities. It captures particles with the use of high magnetic

strength. The collected contaminants are then unleashed into the

discharge chutes.

Basic Function of Multi-layer Circular Vibrating Screen Machine For Chocolate Drink Powder:

1. Grading

Each model of vibrating sieve machine can precisely and

continuously screen and separate screened products, the multi-layer

type can screen and separate five groups of different particles at

a time. It is suitable for dry materials.

2. Solid-liquid separation

The mixture of solid and liquid can be separated effectively by

single or multi-layer type into different grade materials.

3. Remove the impurity

The model can quickly separate a few oversize or undersized

particles from a quantity of materials.

Technical Parameters of Multi-layer Circular Vibrating Screen Machine For Chocolate Drink Powder:

| Model | Power | Screen Surface Diameter | Effective Screening Area (m2) | Layers |

| AY-400 | 0.18 KW | 350mm | 0.0962 | 1~3 |

| AY-600 | 0.25 KW | 550mm | 0.2375 | 1~3 |

| AY-800 | 0.55 KW | 750mm | 0.4416 | 1~3 |

| AY-1000 | 0.75 KW | 920mm | 0.6644 | 1~3 |

| AY-1200 | 1.1 KW | 1120mm | 0.9847 | 1~3 |

| AY-1500 | 1.5 KW | 1420mm | 1.5829 | 1~3 |

| AY-1800 | 2.2 KW | 1720mm | 2.3223 | 1~3 |

| AY-2000 | 3.0 KW | 1920mm | 2.89 | 1~3 |

Overall Dimensions of Multi-layer Circular Vibrating Screen Machine For Chocolate Drink Powder:

| Model | A | B | C | D | E | F | G | I | Single Layer Height | Double Layer Height | Three Layer Height |

| AY-400 | 472 | 372 | 150 | 400 | 110 | 60 | 300 | 270 | 550 | 660 | 770 |

| AY-600 | 570 | 450 | 200 | 600 | 120 | 80 | 380 | 340 | 730 | 865 | 1000 |

| AY-800 | 690 | 570 | 200 | 800 | 130 | 100 | 550 | 340 | 730 | 865 | 1000 |

| AY-1000 | 810 | 690 | 250 | 970 | 150 | 120 | 650 | 400 | 790 | 925 | 1060 |

| AY-1200 | 970 | 850 | 250 | 1170 | 180 | 130 | 760 | 450 | 860 | 1025 | 1190 |

| AY-1500 | 1180 | 1060 | 250 | 1470 | 200 | 140 | 950 | 480 | 985 | 1180 | 1370 |

| AY-1800 | 1480 | 1360 | 350 | 1770 | 220 | 150 | 1110 | 520 | 1030 | 1220 | 1410 |

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

WhatsApp/WeChat: 0086-15637361027

Website: https://www.aarealmachine.com