EVERSUN Machinery (Henan) Co., Ltd |

|

Verified Suppliers

|

EVERSUN Gyratory Screen EFYB-1030 Quartz Sand Sieving Machine

Introduction

EVERSUN rectangular gyratory sieve is used for sizing frac sand, limestone, petroleum coke, silica sand or quartz sand particles.

Its screening accurary can realize above 98%. Because of its higher capacity, higher accuracy, it is widely used in sand screening

and other high-end industry around the world.Gytratory screen is one ideal machine for very large capacity screening purpose.

Rectangular sifter adopts a fully enclosed structure, which is easy to install and control. The general design is 3 ~ 5 layers, and it

can grade 4 ~ 6 sizes of materials in the same time. User can customized the number of screen layers as required.

| Name: | EVERSUN Gyratory Screen EFYB-1030 Quartz Sand Sieving Machine | ||

| Model | EFYB-1030 | ||

| Layer | 1~8 | ||

| Power | 2.2kw | ||

| Mesh Size | 2~500 | ||

| Motor | Italy OLI motor, Swiss ABB motor | ||

| Voltage | Customized | ||

| Materials | Carbon Steel, SUS304, SUS316L | ||

| Dimension | Length:3600mm | Width:1600mm | Height:Customized |

| Application | powder, granule, bulk solids, liquid | ||

| Customized service | Available | ||

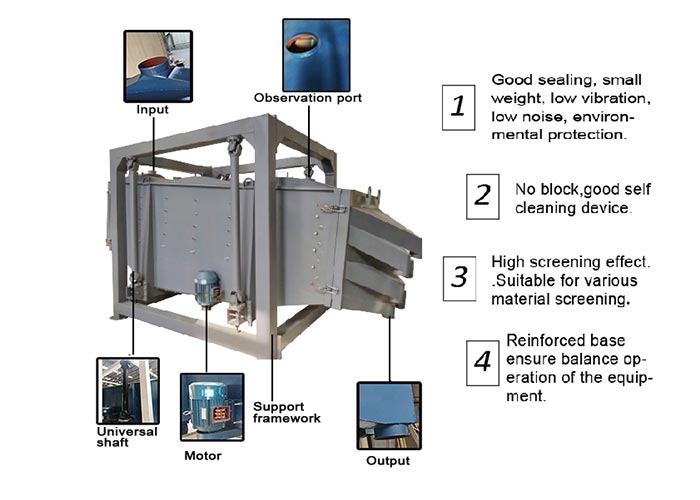

Product Structure

Advantage:

Our Service

Working principle:

Rectangular gyratory screen is also called reciprocating screen, if see from the motion trail of screen box. The vibratory force

produced by its driving device is the inertial force twining along the dead axle, the direction of which is change according to a

certain regular. The essence of rectangular gyratory screen is the reciprocating inertial force formed by the rotation of eccentric

wheel winding the dead axle. According to the structure characteristics and working principle of swinging screen, the screen

surface is arranged with level or incline (angle of inclination is 0-5 degree). After turn on the gyratory screen, the screen box

take reciprocating movement under the inertial force, screen box drives screen surface to make periodic shaking, which makes

the materials on the screen surface to make directional jumping movement with the screen box. During the period, the material

less than the screen aperture falls to under layer, the material bigger than the screen aperture make jumping movement,

discharged from the coarse outlet.

Application

Chemical,food,sugar,salt,ceramsite,mining,metallurgy,feed,fertilizer,medicine,fracturing sand, coated sand, proppant,

activated carbon, imestone, petroleum coke, plastic masterbatch, PC powder. The application of various industries has

proved its screening, separation of durability, reliability and accuracy, and has irreplaceable advanced and efficient

screening capabilities.

FAQ

Q: How to choose the right machine

A: Our engineers will provide suitable machine model based on the

use condition of clients, so please let us know below information:

What materials do you handle and the density.

What capacity do you need for one hour

What mesh number do you need

After knowing above info, our experts will work out the right model

for your purpose.

Q: Is it special requirement available?

A: Yes, the equipment could be designed according to customer's

using aim or special requirements.

Q: How long will my order take?

A: Normal delivery is about 7 working days. Ending delivery

schedule depends on the quantity and items you ordered.