Labtone Test Equipment Co., Ltd |

|

Verified Suppliers

|

|

100kg Payload Mechanical Shock Test Machine, Table Size 70*80 cm Meet MIL- STD -810F

Multi test-conditions application

High Reproducibility

Easy Maintenance for Long Term Usage

No-brainer Tester to operate

Easy Setting with Simple Construction

Set-up by Double-Layered Shock Absorber

Mode Specifications

| Model | SKT30 | SKT50 | SKT100 | SKT200 | SKT300 | SKT600 | SKT1000 | |

| Table size (cm) | 40*40 | 50*60 | 70*80 | 100*100 | 120*120 | 150*150 | 200*200 | |

| Maximum Specimen Weight(Kg) | 30 | 50 | 100 | 200 | 300 | 600 | 1000 | |

| Max acceleration(G) | half sine | 600 | 600 | 600 | 500 | 500 | 300 | 300 |

| saw-tooth waveform | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| square | 150 | 150 | 150 | 150 | 100 | 100 | 100 | |

| Pulse Duration (ms) | half sine | 40—0.2 | 40~1 | 40~1 | 30~2 | 20~3 | 20~3 | 20~3 |

| saw-tooth waveform | 18~6 | 18~6 | 18~6 | 18~6 | 18~6 | 18~6 | 18~6 | |

| square | 30~6 | 30~6 | 30~6 | 30~6 | 30~6 | 30~6 | ||

| Machine Dimension(cm) | 120*110*245 | 130*140*260 | 130*120*260 | 150*130*260 | 200*160*300 | 230*180*310 | 250*220*310 | |

| Controller cabinet Dimension(cm) | W55*D50*H80 | |||||||

| Machine Weight(Kg) | 1900 | 2300 | 3200 | 4200 | 8500 | 15500 | 19500 | |

| Utility | 3-phase AC380V 50/60Hz 0.5~0.8MPa | |||||||

| Requirements | ||||||||

| Conforming standards | GB/T2423-2008 GJB1217 GJB360.23 GJB150 GJB548 MIL-STD-202F IEC-68-2-27 MIL-STD-883E MIL-STD-810F ISTA UL | |||||||

Applications

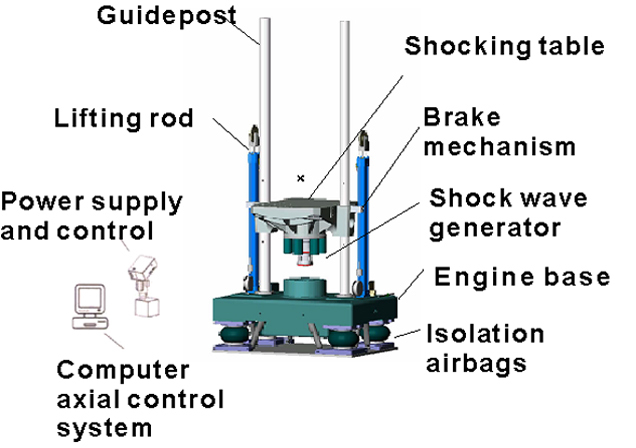

Shock test System Block Diagram

Services

Presales:

In-Sales:

After-Sales:

Production Line: