Labtone Test Equipment Co., Ltd |

|

Verified Suppliers

|

|

3-axis Vibration Testing Machine With Head Expander and Vibration Controller

Vibration Test Systems

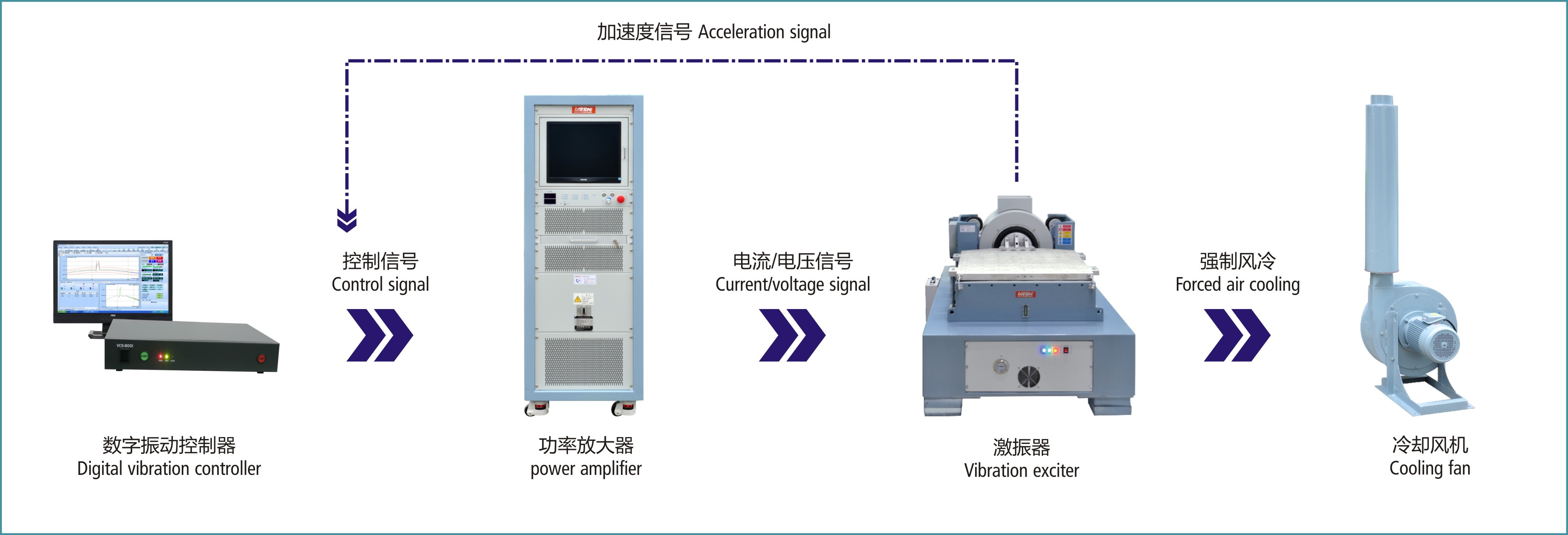

EV series of electromagnetic vibration testing system simulate the vibration environment under the laboratory condition, and test the impact strength as well as reliability of various vibration test applications. In the laboratory, with the aid of vibration testing system, simulations of reproduction of sinusoidal, random, resonant search and dwell, classical shock and road models, etc. can be achieved. It is essential for product quality assurance, new product research and development.

Specifications: EV203-EV220

| Model | EV203 | EV206 | EV210 | EV220 |

| Vibration Generator | VG300/40 | VG300/50 | VG1000/50 | VG2000/50 |

| Frequency(Hz) | 2-2500 | 2-3000 | 2-3000 | 2-2500 |

| Max Exiting Force(kg.f) | 300 | 600 | 1000 | 2000 |

Max. Displacement (mm p-p) | 40 | 50 | 50 | 50 |

| Max. Acceleration(g) | 100 | 100 | 100 | 100 |

| Max. Velocity(cm/s) | 120 | 200 | 200 | 200 |

| Payload(kg) | 120 | 200 | 300 | 400 |

| Armature Mass(kg) | 3 | 6 | 10 | 20 |

| Armature Diameter(mm) | φ150 | φ200 | φ240 | φ320 |

| Cooling Method | Forced Air Cooling | |||

| Vibration Generator Weight(kg) | 460 | 920 | 1100 | 1600 |

| Vibration Generator Dimension L*W*H(MM) | 750*555*670 | 800*600*710 | 845*685*840 | 1200*870*1100 |

| Power Amplifier | Amp3k | Amp6k | Amp12k | Amp22k |

| Cooling Method | Forced Air Cooling | |||

| Power Amplifier Weight(kg) | 250 | 320 | 350 | 500 |

| Power Amplifier Dimension L*W*H(MM) | 800*550*1250 | 800*550*1250 | 800*550*1520 | 800*550*1520 |

| Utility Requirements | 3-phase AC380V ±10% 50Hz | |||

| Aggregate Capacity(KW) | 9 | 20 | 25 | 35 |

Applicable Standards:

MIL-STD, DIN, ISO, ASTM, IEC, ISTA, GB, GJB, JIS, BS etc.

Applicable Industries:

utomotive, Electronics, Aviation, Vessel, Telecommunication, Military Industry, Measuring Instrument etc.

Features:

Working Principle:

Test requirements and model selection guide

To choose a suitable vibration test system, the most important thing is to know the exciting force required to perform the vibration test. To evaluate and calculate the exciting force, the following test specifications should be known:

Clear Testing Requirements:

The specimen fixation is selected based on the upper limit of test frequency and specimen size, either vertical expansion platform or horizontal slip table. Specimen mass is needed to evaluate the required exciting force for vibration test.

Evaluation of Armature Mass

When evaluating the exciting force needed for vibration test, you can choose a temporary armature mass (according to the model of EV series)

Customer Services:

Presales

In-Sales

After-Sales