Labtone Test Equipment Co., Ltd |

|

Verified Suppliers

|

|

Durable Electrodynamic Vibration Shaker With Factory Price For Product Reliability Test

Introduction:

EV series of electromagnetic vibration testing system simulate the vibration environment under the laboratory condition, and test the impact strength as well as reliability of various vibration test applications. In the laboratory, with the aid of vibration testing system, simulations of reproduction of sinusoidal, random, resonant search and dwell, classical shock and road models, etc. can be achieved. It is essential for product quality assurance, new product research and development.

EV series of electromagnetic vibration testing system is specially designed to meet the need for long time operation. Vertical and horizontal vibrations can be achieved by the installation of vibration resistant base. The standard platform is equipped with high efficiency airbag shock isolation device, so that the vibration transmitted to the building can be minimized. There is no need for additional foundation in most of the cases.

A complete set of vibration testing system is composed of shaker, power amplifier and vibration measuring control system, in accordance with the relevant national and international standards (such as: MIL-STD, DIN, ISO, ASTM, IEC, ISTA, GB, GJB, JIS, BS, etc.) to provide technical support for establishing product quality inspection.

Features:

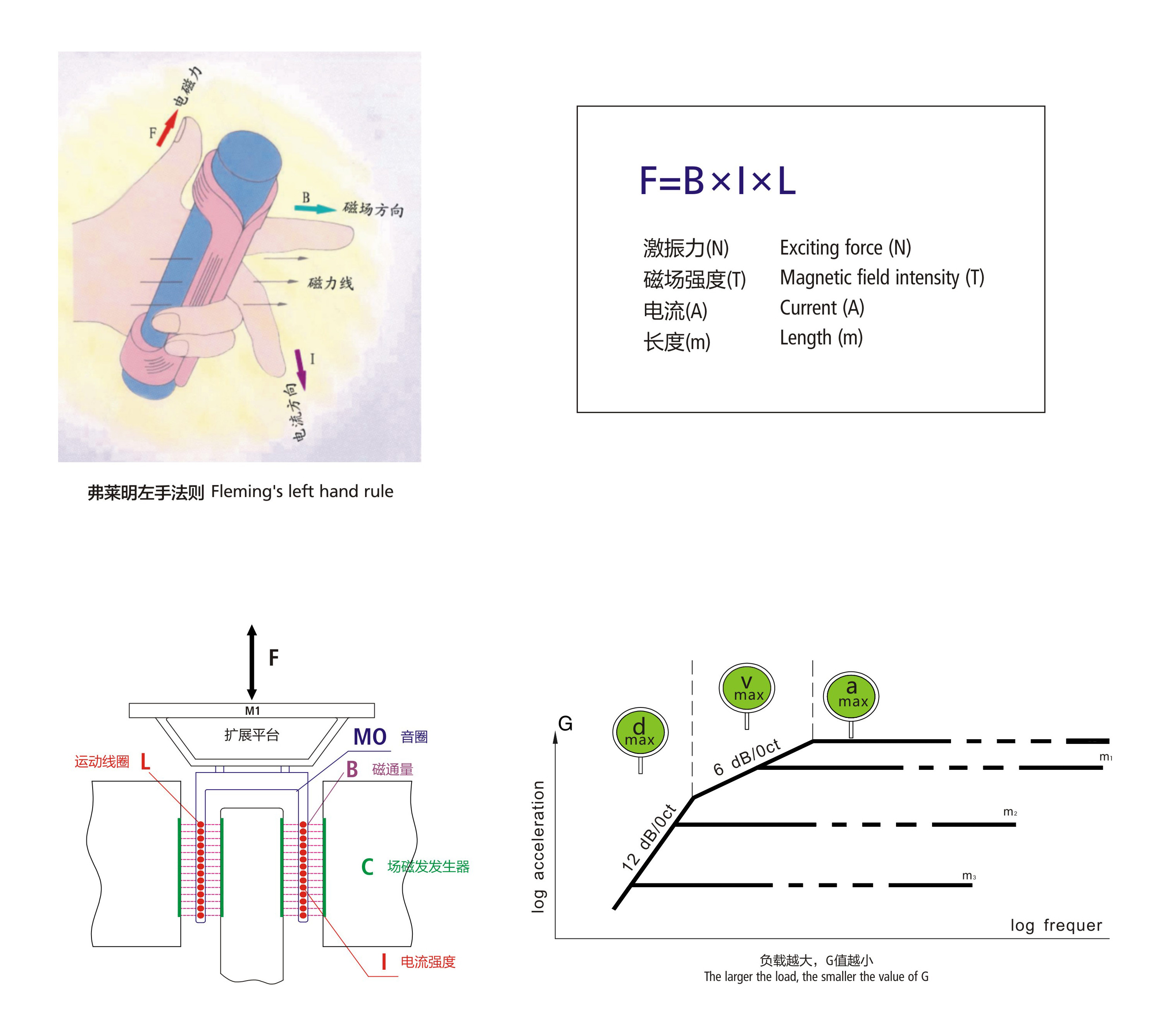

Working Principle:

Specifications: EV103-EV220

| Model | EV103 | EV203 | EV106 | EV206 | EV210 | EV220 |

| Vibration Generator | VG300/25 | VG300/40 | VG600/25 | VG300/50 | VG1000/50 | VG2000/50 |

| Frequency(Hz) | 2-4000 | 2-2500 | 2-3000 | 2-3000 | 2-3000 | 2-2500 |

| Max Exiting Force(kg.f) | 300 | 300 | 600 | 600 | 1000 | 2000 |

| Max. Displacement (mmp-p) | 25 | 38 | 25 | 50 | 50 | 50 |

| Max. Acceleration(g) | 100 | 100 | 100 | 100 | 100 | 100 |

| Max. Velocity(cm/s) | 200 | 120 | 180 | 200 | 200 | 200 |

| Payload(kg) | 110 | 120 | 200 | 200 | 300 | 400 |

| Armature Mass(kg) | 3 | 3 | 6 | 6 | 10 | 20 |

| Armature Diameter(mm) | φ150 | φ150 | φ200 | φ200 | φ240 | φ320 |

| Cooling Method | Forced Air Cooling | |||||

| Vibration Generator Weight(kg) | 460 | 460 | 720 | 920 | 1100 | 1600 |

| Vibration Generator Dimension L*W*H(MM) | 750*560*670 | 750*555*670 | 800*600*710 | 800*600*710 | 845*685*840 | 1200*870*1100 |

| Power Amplifier | Amp3k | Amp3k | Amp6k | Amp6k | Amp12k | Amp22k |

| Cooling Method | Forced Air Cooling | |||||

| Power Amplifier Weight(kg) | 250 | 250 | 320 | 320 | 350 | 500 |

| Power Amplifier Dimension L*W*H(MM) | 800*550*1250 | 800*550*1250 | 800*550*1250 | 800*550*1250 | 800*550*1520 | 800*550*1520 |

| Utility Requirements | 3-phase AC380V ±10% 50Hz | |||||

| Aggregate Capacity(KW) | 8 | 9 | 18 | 20 | 25 | 35 |

Customer Services

Presales:

In-Sales:

After-Sales:

Detailed Pictures: