Xinxiang Tongxin Machinery Co., Ltd. |

YBS Series Tumbler Screening Medicine Powder Chemical Metallurgy Industry

Brief Introduction

Tumbler screen machine is a kind of inertial equipment with mature technology and classical application. Its new design Philosophy and unique structure making it the closest manual screen machine.

The Tumbler screen have bright application prospects for its perfect screening effect. From the aspect of its trajectory, it is a non-linear inertial vibrating screen. The Tumbler screen is particularly used to classify small materials and fine powder according to its unique structure and working principle.

It is not only apply to dry sieving, but also wet sieving.It is widely used in mine, building material, metallurgy, foundry, abrasive material, chemical, light industry, medical, food and other industry.

Its screen and frame are made by different materials and designed by different craft work.Its whole sealing structure prevents materiel dust moving out, so no worry about air pollution;On the other hand, it is very easy to add drying, cooling, dedusting, cleaning and other supporting facilities as part of the Tumbler screen.

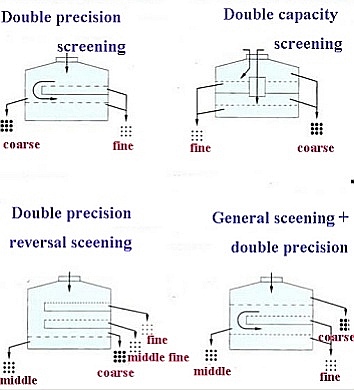

Screening Schemes

| Rotary Screen | Two layers of the same size screen allow the material to be screened once again to achieve higher screening accuracy. |

| Rotary Reverse Screening | Material screening by fine - medium fine- medium- coarse screening, coarse material plays a role in cleaning mesh. |

| Double Processing Screen | The material entering the screen machine is evenly distributed on two levels, so that the processing capacity of a single screen machine is nearly doubled, one screen machine can be used as two screen machine. |

| Combined Screen | Ordinary screen + rotary screen, can improve the use rate of a single screen machine. |

Features

1. Precise to Level 6 classification, up to 90%-95% of screening efficiency;

2. Adopting silicone rubber ball, ultrasonic and other high efficient screen cleaning device system, no blocking of screen opening;

3. Enclosed, dust removal, safe operation; acceleration is 4.5 times lower than that of vibrating screen, longer life of screening parts, less maintenance;

4. Noise <75 decibel;

5. Optimization of weight balance, low foundation dynamic load.

Application

Suitable for mining, casting, abrasive, building

materials, cement, chemical industry, chemical fertilizer,

medicine, light industry, paper making, food, grain industry, salt

industry, grain and other granule, powder related industries dry

wet screening, liquid solid separation waste water screening

recovery and other occasions.

Working Principle

The basic rotary motion is similar to that of the artificial sieve, and the eccentricity ratio is adjustable from 25 to 40mm, and the low speed V type belt drive can be adjusted from 120 to 360rpm.

The residence time of each product can be adjusted by the radial direction and the tangential angle of the swinging screen.

Therefore, established the level and throwing three-dimensional tumbling motion. from the center to the outer edge in the sieve surface is uniformly dispersed, to in a spiral motion to the axial propagation. Thus fine particles complete the whole screening process.

Horizontal and vertical acceleration with the movement of the material increased, and close to the aperture size of particles subsequently successfully separated ;Larger particles were transported to the exit, the outlet is controlled by an adjustable guide device, which is another factor that controls the retention time of the material.

The process is repeated among each layer of screen.

Technical Parameters

| Type | YBS600 | YBS1000 | YBS1200 | YBS1600 | YBS2000 | YBS2400 | YBS2600 |

| Diameter | 600 | 1000 | 1200 | 1600 | 2000 | 2400 | 2600 |

| Sieving area | 0.29 | 0.71 | 1.11 | 1.83 | 2.62 | 3.63 | 5.31 |

| Space requirement | 0.4 | 1.2 | 1.6 | 2.5 | 3.6 | 5.2 | 6.8 |

| Maximum layer of screen | 5 | ||||||

Note: this is only for reference and products specification should

be studied from the real products provided. Can be customized

according to customer requirements.

Our Service

1. We Provide video installation instructions;

2. We offer 24-hour online consulting service;

3. 20 years production experience to ensure quality;

4. We have thorough data to ensure the quality;

5. We provide detailed instruction an product information.

If you want to get more information of product, please contact us!