Suzhou Best Bowl Feeder Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

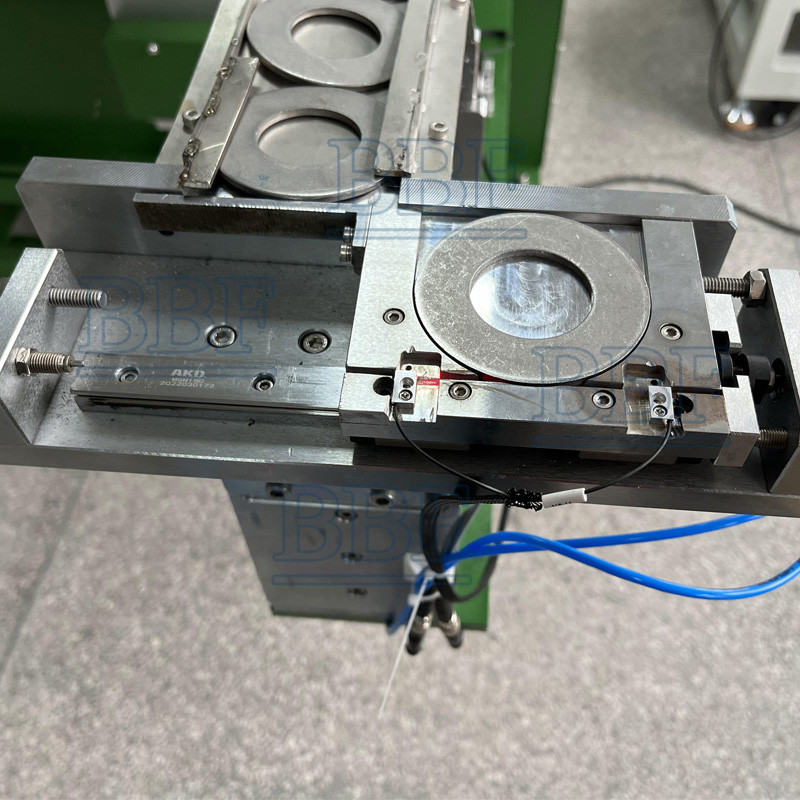

Customized Step Feeder Steel Rods Washers Rivet Step Feeding Machine

1 . Descriptions:

An industrial step feeder, also referred to as a step feeder conveyor, is a specialized material handling equipment extensively used in industrial automation and manufacturing processes. Its primary purpose is to transport and orient parts or components with precision, ensuring that they are presented individually to downstream machinery or assembly stations in a specific orientation.

The name "step" derives from its distinctive design, resembling a series of steps that facilitate the orderly movement of parts. Key characteristics and functionalities of industrial step feeders include:

Part Orientation: Step feeders are designed to align parts or components as they traverse the conveyor, ensuring their correct positioning for subsequent operations like assembly, inspection, or packaging.

Sequential Feeding: These feeders release one part at a time, enabling a controlled and consistent flow of parts to the succeeding stages of the manufacturing or assembly process.

Adjustable Design: Many industrial step feeders can be customized to accommodate parts of varying sizes, shapes, and weights. The steps can be modified to suit the specific requirements of the handled parts.

Precision and Accuracy: Step feeders are engineered to operate with precision and accuracy, minimizing the occurrence of jams, collisions, or misaligned parts during the feeding process.

Automation Integration: Step feeders are commonly integrated into automated manufacturing or assembly lines, working in conjunction with robots, conveyor systems, and other equipment to optimize production efficiency.

Versatility: Their ability to handle a wide range of parts makes them suitable for applications across diverse industries, including automotive, electronics, consumer goods, and medical devices.

Industrial step feeders play a vital role in scenarios that demand meticulous part orientation and sequential feeding, ensuring that parts are delivered to downstream machinery or assembly stations accurately and punctually. By enhancing efficiency and consistency in manufacturing and assembly processes, they contribute to reduced manual handling and increased productivity.

2 . Specifications:

| Product name | Step Feeder |

| Material | Aluminum(AL7075), Stainless Steel(SUS304) or Based on Customers' Requirements |

| Controller | CUH,Sanki,Sinfonia,REO,Afag |

| Voltage | 220V 50HZ/110V 60Hz or Based on Customers' Requirements |

| Power | 300W/500W/1000W/1500W/2000W |

Material Speciality | Excellent Processing Properties,High Strength, High Hardness |

| Speed | Based on Customers Requirements |

| Warranty | 2 Years |

| Certification | CE, ISO9001, ROHS |

| Lead Time | 3 Working Weeks |

3 . Choosing Between Stepper Feeders and Vibratory Bowl Feeders :

When choosing between stepper feeders and vibratory bowl feeders for your application, it's essential to analyze their various features. Here, we focus on three key features:

Setup:

Stepper feeders are customizable, allowing the customer to adjust

the step cycle precisely to meet their production cycle

requirements using a variable frequency drive.

Vibratory bowl feeders rely on gravity and vibrations, which can

sometimes lead to parts being thrown or dropped onto the tracks.

Tweaking may be necessary to ensure the feeder meets the

application's needs.

Part Integrity:

Vibratory feeder tracks can be designed with specific materials,

such as stainless steel, to ensure parts integrity, meeting

sterility and durability standards. For easily scratched parts, a

soft material coating can be applied.

Stepper feeders maintain part integrity by providing smooth motion

without requiring parts to be dropped or thrown, thanks to the air

system.

Noise Levels:

Vibratory feeders, due to the metal tracks and steel design, can

produce noise during operation. Installing a sound enclosure around

the feeder bowl can help mitigate this.

Stepper feeders, with their step operation and air system, function

quietly. Some stepper feeders may include elevators with rubber

belts, further reducing noise.

These features are among the primary considerations when purchasing

an electric feeder. Understanding these and other factors will help

you determine which feeding system will provide the most benefits

for your application.

4 . More Pictures: