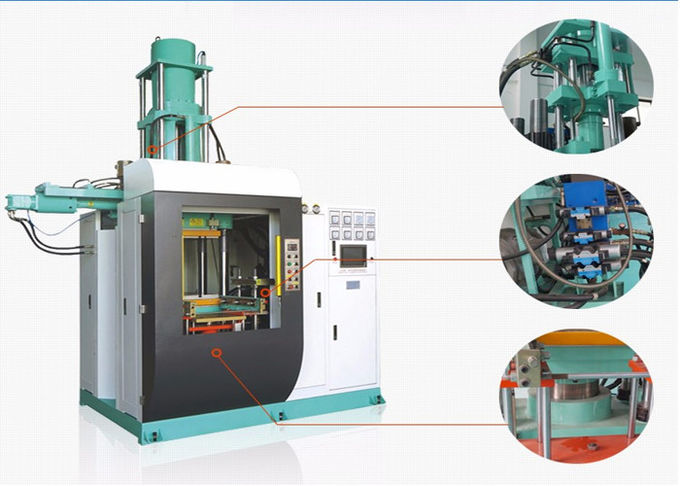

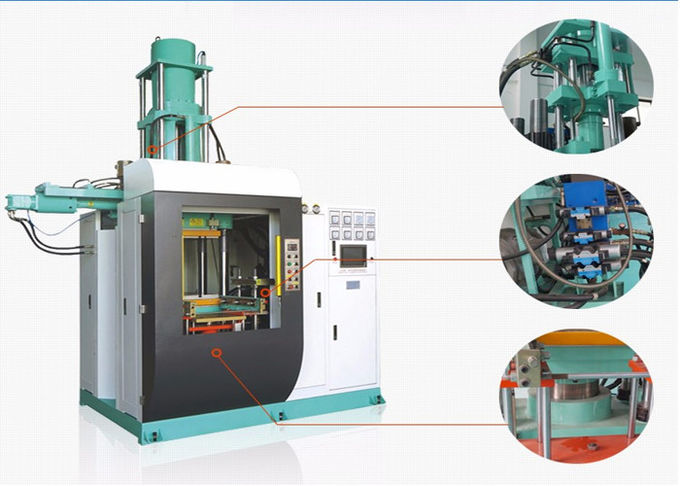

Auto Parts Rubber Injection Molding Making Machine For Making

Rubber Wire Harness Bellows

Detailed Product Description

| Product Name: | JC-1000VI-AO | Pressure Type: | Oil Hydraulic Press |

|---|

| Clamp Force: | 1000Ton | Apply Material: | Silicone Or Rubber Or NBR |

|---|

| Machine Dimension: | 3750x3050x5000mm | Injection Mode: | Sprueless Injection |

|---|

| Patent: | Anti-collision Molding System |

|---|

| High Light: | hydraulic power press machine,silicone bracelet maker machine |

|---|

Auto Parts Making Rubber Injection Molding Machine For Making

Rubber Wire Harness Bellows

Machine Type:

- Rubber molding machine, hydraulic molding machine, transfer rubber

press, hydraulic injection

- 1000Ton clamp force with large production capacity and high

quality.

- All-in-out structure, sprueless injection without material lass

controlable injecting material temperature.

- Stable working performance, can normally runing for over 5 years

without any mechinery problems

- Low working noises, can bring a quiet working environment

Applications :

"all-in-out" series silicone rubber injection molding machine is

advanced rubber molding technology, it's structure is compact with

wide applicability, high efficiency and high quanlity.

Especially it is suitable for the rubber products of complex

shapes, exhausting difficultly, difficult to molding, and need high

precision injection.

Own Patented "all-in-out" Technology:

- Visible Feeding System:

- Avoid the traditional techniques which cannot know about the

situations like temperature/hardness/ Plasticizing before

vulcanizing,

- Efficiently get control of the raw material Plasticizing status,

can make adjustment in time.

- Excellent Plasticizing Effects:

- Excellent Plasticizing effects, reduce the waste rubber material, avoid blocking the cylinder, save much more raw material when

plasticizing.

- Easy to switch the different colors of raw material,easy for cleaning.

- High Temperature Ranges:

- Simple structure, Plasticizing temperature between 90 ℃ and 100 ℃,

ensure good Plasticizing effects.

- Good Plasticizing effects can ensure a good injection products.

- Save Raw Rubber Material:

- Can handle with the raw rubber material as hardness as 85°.

- Improve coefficient of utilization of raw material.

- all material in, and all out:

- All-in-out structure, sprueless injection without material loss

controlable injecting material temperature

- Excellent for high precision molding parts

Specific Charateristics:

Suitable for automotive and electronic rubber parts, high / cold

temprature precision rubber parts, especially NBR products.

All-in-out structure, sprueless injection without material loss

controlable injecting material temperature.

Excellent for high precision molding part

5-10 times better accuracy than conventional injection machine the

measuring precision of 1000cc injection volume is up to ±0.1g

Anti-collision molding system prevent mold damage occurring from

misalignment(patented)

Servo-controlled system up to 40% energy saving

Proportional backpressure controlling characteristic

Intellectual Property Rights:

"all-in-out" injection structure technology

Anti-collision molding system

Energy saving for 40%

Main Technical Parameters:

| Model | Unit | 50VI-AO | 100VI-AO | 200VI-AO | 300VI-AO | 400VI-AO | 600VI-AO | 800VI-AO | 1000VI-AO |

| Clamping Force | Ton | 50 | 100 | 200 | 300 | 400 | 600 | 800 | 1000 |

| Injection Capacity | cc | 500 | 500 | 2000 | 3000 | 4000 | 6000 | 8000 | 10000 |

| Injection pressure | kgf/cm² | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 |

| Operation table size | mm | 300*300 | 400*400 | 550*560 | 700*700 | 700*700 | 850*850 | 1000*1000 | 1200*1200 |

| Min. Mold Thickness | mm | 50 | 50 | 100 | 100 | 100 | 100 | 150 | 150 |

| Plunger stroke | mm | 300 | 350 | 400 | 400 | 400 | 500 | 500 | 500 |

| Distance of Thermo-plate | mm | 350~450 | 400~500 | 500~600 | 500~600 | 500~600 | 600~700 | 650~800 | 650~800 |

| Distance of Tie bar | mm | 400*140 | 515*230 | 640*310 | 820*395 | 820*395 | 970*500 | 1140*600 | 1340*800 |

| Die sinking type | 2RT-3RT-4RT-Upper Mold-Lower Mold |

Max. Operating Pressure | Mpa | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Motor Power | hp | 7.5 | 10 | 15 | 15 | 15 | 20 | 20 | 25 |

| Electric Heating Power | Kw | 8.4 | 10 | 15.3 | 24 | 24 | 29.75 | 35 | 42 |

| Total Power | Kw | 16.9 | 20.5 | 30.3 | 39 | 39 | 48.75 | 54 | 64.5 |

| Gross weight | Ton | 5.5 | 6 | 7.5 | 9 | 10 | 14.2 | 17.5 | 21 |

Dimension (L*W*H) | mm | 2000*1500 *H2800 | 2400*1650 *3200 | 2600*2000 *4000 | 2750*2265 *4200 | 2750*2265 *4200 | 3200*2500 *4350 | L3450*W2750 *H4500 | 3750*3050 *5000 |