Dongguan Jintong Plastic Machinery Co., Ltd. |

|

Verified Suppliers

|

|

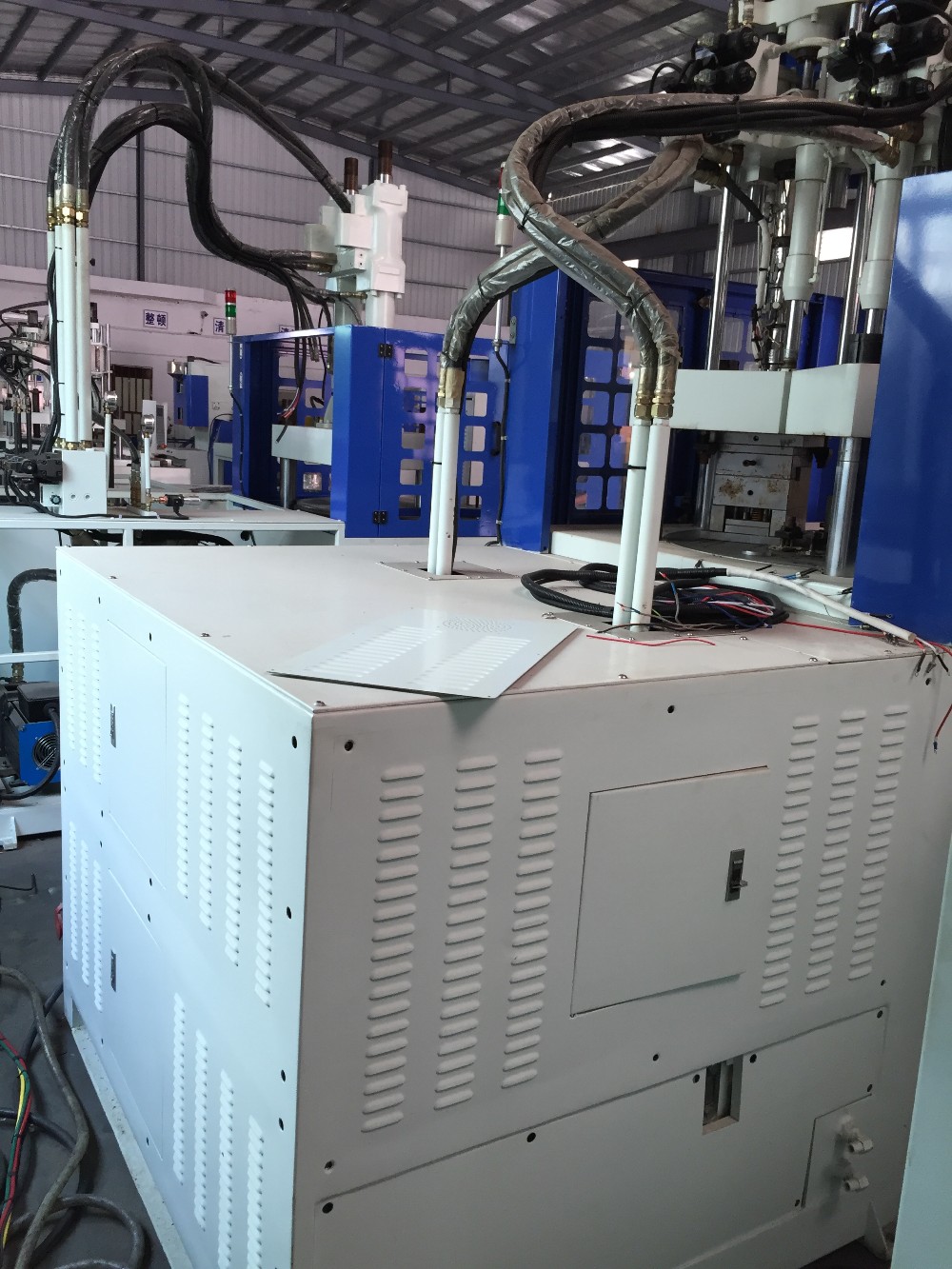

120T Accuracy Injection Molding Machine For Diamond Cutting Wire

| UNIT | JTKR-1200 | ||

| INJECTION SYSTEM | screw diameter | mm | 35 |

| injection pressure | kg/cm² | 3044 | |

| theoretical shot volume | cm³ | 183 | |

| max shot weight | g | 163 | |

| shot rate | oz | 112 | |

| screw stroke | mm | 180 | |

| screw speed | rpm | 25-320 | |

| nozzle contact force | Tons | 1.6 | |

| nozzle stroke | mm | 245 | |

| number of temperature control | 5 | ||

| CLAMPING SYSTEM | clamping force | Tons | 123 |

| opening force | Tons | 23 | |

| platen size | mm | 760*480 | |

| distance between tie bar | mm | 1080*350 | |

| min mold height | mm | 125 | |

| opening stroke | mm | 250 | |

| max open daylight | mm | 375 | |

| up ejector out force | Tons | 8.7 | |

| up ejector in force | Tons | 7.9 | |

| low ejector out force | Tons | 2.8 | |

| low ejector in force | Tons | 2.1 | |

| up ejector stroke | mm | 69 | |

| low ejector stroke | mm | 99 | |

| HYDRAULIC SYSTEM | pump output | cc | 116 |

| oil reservoir capacity | L | 450 | |

| motor power | kw | 14 | |

| motor speed | r/min | 960 | |

| heating power | kw | 10 | |

| total power | kw | 24 | |

| OTHER | machine dimension | m | 3.5*1.6*3 |

| weight | T | 6.5 |

1) vertical clamping, horizontal injection,

2) clamping force, injection weight and shot speed can be changed according to actual demand.

PRODUCT ADVANTAGE

Energy-saving: save 30% energy compared to similar products by

using SIFU pump system

High efficiency: SIFU motor have max speed 2200/min to increase oil

pump output and improve more than 15% productivity speed

Low heating: save 55% cooling water quantity at least compared to

similar products

Low noise: optimize motor working condition with imported bearing

and oil pump to reduce 15-20db working noise

Precision: use completely close-cycle control with pressure sensor

and motor rotary encoder to improve product consistency

SERVICE ADVANTAGE

17 years of customer service experience and summarizing customer feedback, Jintong develop a systematic and standardized service process, and also establish 24 hour response mechanism to wensure timely solve customers problems and offer perfect service to customers as soon as possible.

91.8% Response Rate

91.8% Response Rate

91.8% Response Rate