SHENZHEN JOINT TECHNOLOGY CO.,LTD |

|

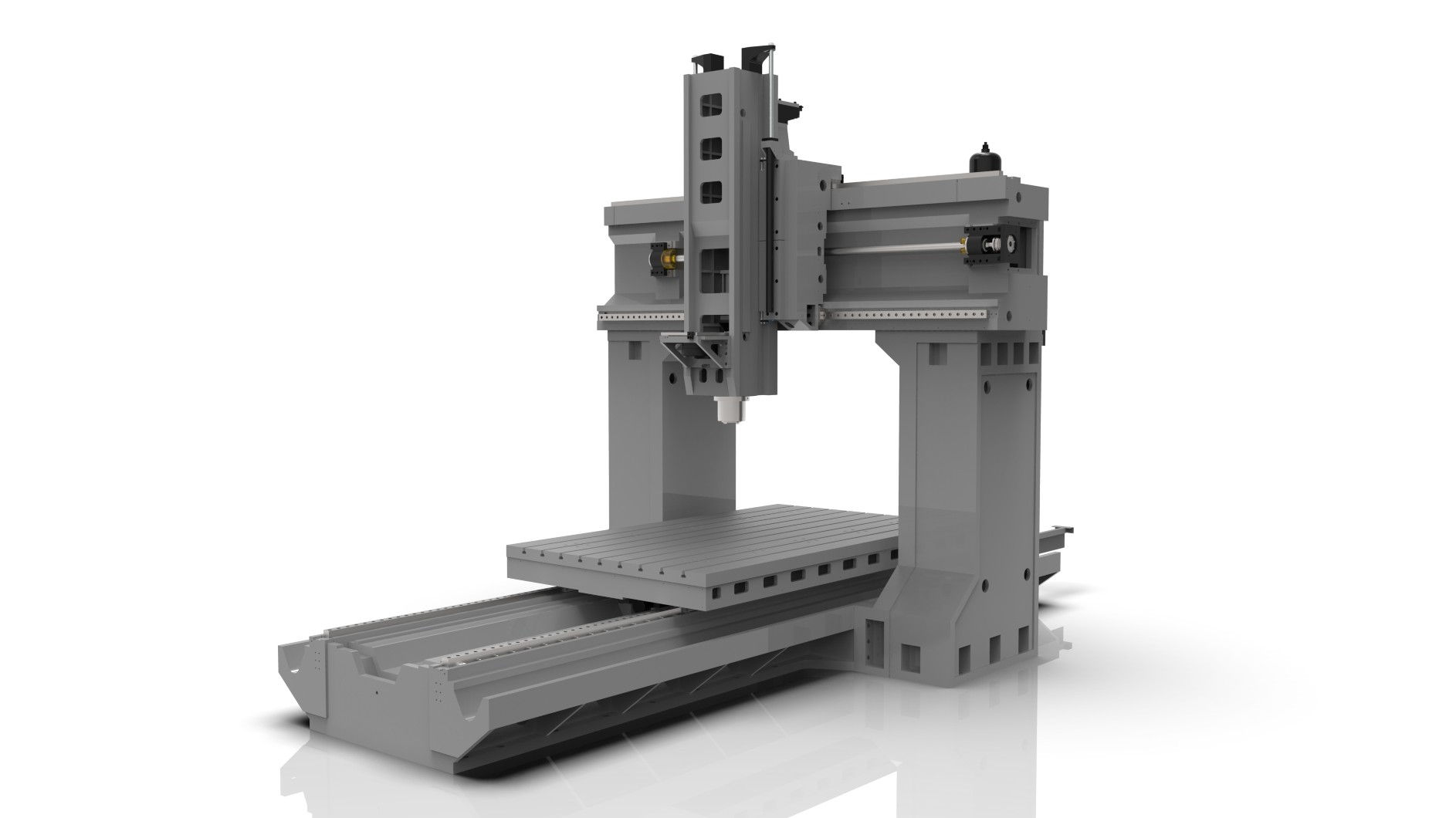

Gantry double column CNC machine center BTMC-1530Q

![]()

1. The structure of machine tool is analyzed with ANSYS at all stages from foundation

design to guarantee of high-speed and high-precision continuous machining. A simulation

test for deformation produced when the center of machine tool bears load is conducted to

guarantee excellent bending rigidity of machine tool.

2. Transverse helical chip conveyor.

3. Arm type tools magazine capability 32 tools or 40 tools.

4. Fanuc oi md, Siemens 828d, Mitsubishi M70, Heidenhain, and so on cnc control sytem for

your choice

5. Fixed beam type structure

6. X,Y axis linear guideway; Z axis box guideway

7. Germany ZF gearbox is optional

8. Hydraulic station is optioanl

![]()

| Model | BTMC-1530Q |

| Table size | 1300*3000mm |

| X/Y/Z travel | 3000*1660*850mm |

| Distance between tool head and table | 240-1090mm |

| Work table Y slot (NO.-size*pitch) | 7-22*175mm |

| Width of gantry | 1650mm |

| Spindle rotation speed | 6000 rpm/min |

| Spindle Taper | BT50 |

| Spindle Motor | 15KW |

| X/Y/Z axis Rapid feed | 8/110/12 m/min |

| Positioning accuracy | 0.01mm |

| X/Y/Z axis Cutting feed | 8 m/min |

| Dimension | 8000*3300*4300mm |

| Net weight | 17000kg |

| Max load of table | 6000kg |

![]()

| 1) Fanuc-OI MF(5) Control System with motor and drive | 9) Automatic lubrication system |

| 2) 6000RPM/15KW/BT50 Taiwan brand belt type spindle | 10) Heat exchange |

| 3) X/Y axis are roller linear way, Z axis is box way | 11) Warning light |

| 4) 1300*3000mm worktable area | 12) Tool and tool box |

| 5) Screw type chip conveyor | 13) Working light |

| 6) Pneumatic system | 14) RS232 Interface |

| 7) Work piece coolant system | 15) Operation manual |

| 8) Spindle oil chiller |

![]()

Precision machinery manufacturer since 1995.

Your reliant expert on moulding and machining equipemnt!

Q1. How can I get a quotation?

A. Leave us massage with your purchase requements and we will reply

you ASAP. And you may contact us directly by Trade Manager or Telephone.

Q2. Can you provide customized machine or SPM (Special purpose machine)?

A. Yes, we provide smart solutions for our customer, in order to increase efficiency.

Q3. Can you provide training for operation CNC machines?

A. Yes, free training in our factory is available.

Q4. How about your price?

A. Send me details about what you need, you will get the best price in China. The price is

competitive over the world.

Q5. What's your warranty terms?

A. We will supply a replacement for parts that prove to be defective

for a period of 12 months,

starting on the machine’s bill of lading date. Extended warranty is available at the time of purchase.

Please contact your Joint sales representative for details.