Changzhou Welldone Machinery Technology Co.,Ltd |

|

Verified Suppliers

|

|

The Spray drying is the technology most widely used in the liquid technology shaping and in the drying industry.The drying technology is most suitable for producing solid powder or particle products from liquid materials,such as:solution, emulsion, suspension and pumpable paste states,For this reason,when the particle size and distribution of the final products, residual water contents, mass density, and the particle shape must meet the precise standard, spray drying is one of the most desired technologies.

After filtering and heating, the hot fresh air enter into the air distributor at the top of drying chamber, distributed in spiral way uniformly from up to down. At the same time, the feeding liquid is pumped to the top atomizer, then be sprayed to extremely fine mist liquid drop. Through the short time of direct contact with hot air, the moisture evaporated at once, the solid remains to be powder. The dry whey powder will be discharged continuously from the bottom of drying tower and cyclone collector, the exhaust air will be discharged after cleaning.

High Efficient Fast Drying Speed Spray Drying Tower of liquid conveying, air filtering and heating, liquid atomization, drying chamber, exhaust collection, and control system, etc. The characteristics of each system are as follows.

1. Liquid conveying system consists of a liquid tank, magnetic filter, pump, etc. to ensure that the liquid enters the atomizer smoothly.

2. Air filtration system and heating system Before entering the heater, the fresh air should pass through the front and rear filters before entering the heater for heating. The heating methods are electric heater, steam radiator, gas furnace, etc. The choice of which method depends on the customer's site conditions. To ensure that the drying medium has high purity when it enters the drying chamber, the heating air should pass through the high-efficiency filter before entering the drying chamber.

3. Atomization system

The atomization system consists of a high-speed centrifugal atomizer with frequency converter, etc. The powder from the high speed centrifugal atomizer is between 40-120 microns.

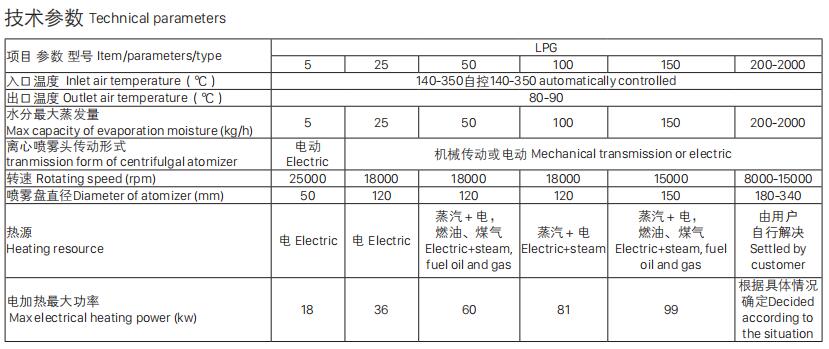

Technical Parameters of High Efficient Fast Drying Speed Spray Drying Tower

Picture of High Efficient Fast Drying Speed Spray Drying Tower